Abstract

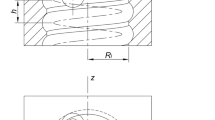

As a new hole-making method, helical milling has been widely used to machine holes on difficult-to-cut materials in the aircraft industry. The accurate prediction of the surface topography and the corresponding surface roughness are essential for optimizing the cutting conditions in order to improve the surface quality of the generated holes. In this paper, the kinematics of helical milling was first analyzed. Subsequently, a mathematical model was established to simulate the three-dimensional surface topography after a helical milling operation, in which the tool eccentricity, the secondary cutting, and also the size effect were taken into account. Further, an in-depth research on the process of extracting surface roughness from the surface topography was conducted. The proposed method is capable of extracting the roughness of the generated hole effectively, and meanwhile the predicted surface roughness is well in harmony with the experimental result. As a result, the developed model in this work can be used in planning and optimizing the cutting conditions.

Similar content being viewed by others

References

Zeilmann RP, Weingaertner WL (2006) Analysis of temperature during drilling of Ti6Al4V with minimal quantity of lubricant. J Mater Process Technol 179(1):124–127

Briksmcicr E, Fangmann S, Meyer I (2008) Orbital drilling kinematics. Prod Eng 2:277–283

Wang H, Qin X, Ren C, Wang Q (2012) Prediction of cutting forces in helical milling process. Int J Adv Manuf Technol 215(9):9–13

Zhou L, Ke Y, Dong H, Chen Z, Gao K (2016) Hole diameter variation and roundness in dry orbital drilling of CFRP/Ti stacks. Int J Adv Manuf Technol:1–14

Tian Y, Liu Y, Wang F, Jing X, Zhang D (2016) Modeling and analyses of helical milling process. Int J Adv Manuf Technol:1–20

Tönshoff HK, Friemuth T, Groppe M (2001) High efficient circular milling: a solution for economical machining of bore holes in composite materials. In Proceedings of the Third International Conference on High Speed Machining, 2001, 287–296, Metz (France)

Liu J, Chen G, Ji C, Qin X, Li H, Ren C (2014) An investigation of workpiece temperature variation of helical milling for carbon fiber reinforced plastics (CFRP). Int J Mach Tool Manu 86(11):89–103

Qin XD, Hua S, Ji XL, Liu WC, Chen SM (2010) Surface roughness model for helical milling of die-steel based on response surface methodology. Key Eng Mater 431-432:346–350

Li Z, Liu Q, Ming X, Dong Y (2014) Cutting force prediction and analytical solution of regenerative chatter stability for helical milling operation. Int J Adv Manuf Technol 73(1):433–442

Fernández-Vidal SR, Mayuet P, Rivero A, Salguero J, del Sol I, Marcos M (2015) Analysis of the effects of tool wear on dry helical milling of Ti6Al4V alloy. Procedia Eng 132:593–599

Denkena B, Boehnke D, Dege JH (2008) Helical milling of CFRP-titanium layer compounds. CIRP J Manuf Sci Technol 1(2):64–69

Liu C, Wang G, Dargusch MS (2012) Modelling, simulation and experimental investigation of cutting forces during helical milling operations. Int J Adv Manuf Technol 63(9):839–850

Daymi A, Boujelbene M, Amara AB, Bayraktar E, Katundi D (2011) Surface integrity in high speed end milling of titanium alloy Ti-6Al-4V. Mater Sci Technol 27(1):387–394

Li SP, Liu DX, Li RH, Xia ML, Zhang W, Qiao MJ, Du DX (2012) Influence of shot peening and surface integrity on fatigue properties of TC21 titanium alloy. Mech Sci Technol Aerosp Eng 31(12):1921–1926 (in Chinese)

Arrazola PJ, Özel T, Umbrello D, Davies M, Jawahir IS (2013) Recent advances in modelling of metal machining processes. CIRP Ann Manuf Technol 62(2):695–718

Xu A, Qu Y, Li W, Zhang D, Huang T (2001) Generalized simulation model for milled surface topography-application to peripheral milling. Chin J Mech Eng 14(2):121–126

Gao T, Zhang W, Qiu K, Wan M (2006) Numerical simulation of machined surface topography and roughness in milling process. J Manuf Sci Eng 128(1):96–103

Li Z, Liu Q (2013) Surface topography and roughness in hole-making by helical milling. Int J Adv Manuf Technol 66(9):1415–1425

Shan YC, He N, Li L, Zhao W, Yang YF (2013) Vector modeling of robotic helical milling hole movement and theoretical analysis on roughness of hole surface. J Cent South Univ 20(7):1818–1824

Shan YC, He N, Li L, Zhang T (2015) Research on hole surface roughness by orbital drilling of Ti6Al4V titanium alloy with simulation and test. Mach Tool Hydraul 43(19):46–50 (in Chinese)

Jiang YD, He GY, Qin XD, Zhao Q (2015) Study on surface integrity of hole in helical milling process of TC4 titanium alloy. Mech Sci Technol Aerosp Eng 34(10):1521–1525 (in Chinese)

Zhang X, Ehmann KF, Yu T, Wang W (2016) Cutting forces in micro-end-milling processes. Int J Mach Tool Manu 107:21–40

Funding

The research is supported by the National Natural Science foundation of China (No. 51420105007) and National Foundation of China (Grant No. 51675371).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Y., Tian, Y., Jing, X. et al. Surface topography modeling and roughness extraction in helical milling operation. Int J Adv Manuf Technol 95, 4561–4571 (2018). https://doi.org/10.1007/s00170-017-1516-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1516-2