Abstract

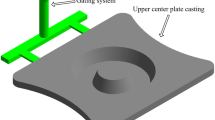

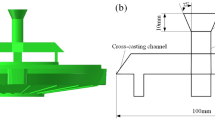

With the continuous development and improvement of computer simulation technology, computer simulation analysis has become an important means for judging the feasibility of casting process design. But computer consumption is also gradually increasing due to the more complex castings, the huge computation quantity and the long cycle of casting process design. Therefore, in order to reduce the computer consumption, a new method for optimal riser design based on geometric reasoning method and fruit fly optimization algorithm in CAD is proposed in this paper. The main focus of the method is to carry out the initial process optimization design of riser purely taking into account the casting geometry based on CAD techniques. Firstly, geometric reasoning method based on implicit surface is used to obtain every hot spot of casting. Secondly, the open source CAD application (HeeksCAD) is used to compute the volume and heat transfer area of casting which need to be compensated. Thirdly, fruit fly optimization algorithm (FOA) is used to optimize the riser geometric sizes. A cylinder sleeve casting is taken as an example to illustrate the feasibility of the methodology. Finally, numerical modeling method confirms the validity of the implementation of the new methodology for optimal riser design. The results indicate that the method could be useful in cutting down the expense and time of casting production cycle, particularly for casting process optimization stage.

Similar content being viewed by others

References

Lampman S (2009) Casting design and performance. ASM International, Ohio

Li YZ, Yang HB, Xing ZW (2017) Numerical simulation and process optimization of squeeze casting process of an automobile control arm. Int J Adv Manuf Technol 88(1–4):941–947. https://doi.org/10.1007/s00170-016-8845-4

Xu Y (2012) Development of 3-D foundry design CAD system for cast steel with sand mold. Shandong University, Dissertation

Khan MAA, Sheikh AK (2016) Simulation tools in enhancing metal casting productivity and quality: a review. P I Mech Eng B-J Eng 230(10):1799–1817

Sutaria M, Ravi B (2014) Computation of casting solidification feed-paths using gradient vector method with various boundary conditions. Int J Adv Manuf Technol 75(1–4):209–223. https://doi.org/10.1007/s00170-014-6049-3

Ransing RS, Sood MP (2006) Optimization in castings—an overview of relevant computational technologies and future challenges. Metall Mater Trans B Process Metall Mater Process Sci 37(6):905–911. https://doi.org/10.1007/BF02735012

Campbell J (2011) Complete casting handbook—metal casting processes, metallurgy, techniques and design. Butterworth-Heinemann, Oxford

Heine RW, Uicker JJ (1983) Risering by computer assisted geometric modeling. AFS Trans 91:127–136

Neises SJ, Uicker JJ, Heine RW (1987) Geometric modeling of directional solidification based on section modulus. AFS Trans 95:25–30

Sirilertworakul N, Webster PD, Dean TA (1993) Computer prediction of location of heat centres in castings. Mater Sci Technol 9(10):923–928. https://doi.org/10.1179/mst.1993.9.10.923

Ravi B, Srinivasan MN (1989) Hot spot detection and modulus computation by computer graphics. 56th World Foundry Congress. Dusseldorf 12:1–12.7

Ravi B, Srinivasan MN (1996) Casting solidification analysis by modulus vector method. Int J Cast Metal Res 9(1):1–8. https://doi.org/10.1080/13640461.1996.11819638

Li W, Cui J (2002) A new method for quickly locating the hot spots in solidification simulation of complicated castings. Int J Cast Metal Res 15(4):319–323

Pao WKS, Ransing RS, Lewis RW, Lin C (2004) A medial-axes-based interpolation method for solidification simulation. Finite Elem Anal Des 40(5):577–593. https://doi.org/10.1016/S0168-874X(03)00097-0

Ransing RS, Pao WKS, Lin C, Sood MP, Lewis RW (2005) Enhanced medial axis interpolation algorithm and its application to hotspot prediction in a mould–casting assembly. Int J Cast Metal Res 18(1):1–12. https://doi.org/10.1179/136404604225022766

Xu Y, Zhang K, Zheng HL, Sun YC, Tian XL (2011) An improved geometric model to predict hot spots of castings. Materials Science Forum. Trans Tech Publ 689:29–32

Sutaria M, Joshi D, Jagdishwar M, Ravi B (2011) Automatic optimization of casting feeders using feed-paths generated by VEM. Proceedings of the ASME 2011 International Mechanical Engineering Congress & Exposition, Denver

Jacob E, Sasikumar R, Praveen B, Gopalakrishna V (2004) Intelligent design of feeders for castings by augmenting CAD with genetic algorithms. J Intell Manuf 15(3):299–305. https://doi.org/10.1023/B:JIMS.0000026568.93342.35

Sethian JA (1999) Level set methods and fast marching methods: evolving interfaces in computational geometry, fluid mechanics, computer vision, and materials science. Cambridge University Press, Oxford

Osher S, Fedkiw R (2006) Level set methods and dynamic implicit surfaces. Springer Science & Business Media, Dordrecht

Chen T (2013) Numerical simulation of casting thermal stress based on finite element method and intelligent techniques. Huazhong University of Science and Technology, Dissertation

Chen T, Liao DM, Shen X, Pang SY, Zhou JX (2013) Application of implicit surface in post-processing of casting simulation. Int J Adv Manuf Technol 69(5–8):1841–1854. https://doi.org/10.1007/s00170-013-5090-y

Zhang YT, Zhao HK, Qian J (2006) High order fast sweeping methods for static Hamilton–Jacobi equations. J Sci Comput 29(1):25–56. https://doi.org/10.1007/s10915-005-9014-3

Zhao H (2005) A fast sweeping method for eikonal equations. Math Comput 74(250):603–627

Dučić N, Ćojbašić Ž, Radiša R, Slavković R, Milićević I (2016) CAD/CAM design and genetic optimization of feeders for sand casting process. Facta Universitatis, Series: Mech Eng 14(2):147–158

Gao SS, Yu ZY (2000) Calculate riser dimensions of steel castings using cubic equation mathematical analytic method. Foundry 49(9):533–537

Pan WT (2012) A new fruit fly optimization algorithm: taking the financial distress model as an example. Knowl-Based Syst 26:69–74. https://doi.org/10.1016/j.knosys.2011.07.001

Pan WT (2011) Fruit fly optimization algorithm. Tsang Hai Book Publishing Co., Taipei

Wu XW, Li Q (2013) Research of optimizing performance of fruit fly optimization algorithm and five kinds of intelligent algorithm. Fire Control & Command Control 38(4):17–20

Wang T, Zhou JX, Yin YJ, Shen X, Zhou Q (2016) Riser optimization based on fruit fly optimization algorithm. Special Casting & Nonferrous Alloys 36(3):246–249

Zhang XL, Liu LQ (2012) Intelligent optimization algorithm and its application in mechanical engineering. National Defense Industry Press, Beijing

Zhou JX, Zhou Q, Chen T, Yin YJ, Shen X (2015) Computation of feed-path based on temperature gradient method. Mater Res Innov 19(S5):811–816

Zhou JX, Wang M, Yin YJ, Shen X, Chen X, Li W, Zhang DQ (2017) Feed paths and hot spots computation based on a time gradient method in casting. Int J Adv Manuf Technol 93(1–4):261–272. https://doi.org/10.1007/s00170-016-8932-6

Funding

This research was financially supported by the National Natural Science Fund Projects, China (no.51605174, no.51475181) and State Key Laboratory of Materials Processing and Die & Mould Technology Research Project (2015–2017).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, T., Yin, Y., Zhou, J. et al. Optimal riser design method based on geometric reasoning method and fruit fly optimization algorithm in CAD. Int J Adv Manuf Technol 96, 53–65 (2018). https://doi.org/10.1007/s00170-017-1496-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1496-2