Abstract

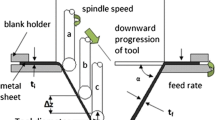

Single point incremental forming (SPIF) process has the potential to replace conventional sheet forming process in industrial applications. For this, its major defects, especially poor geometrical accuracy, should be overcome. This process is influenced by many factors such as step size, tool diameter, and friction coefficient. The optimum selection of these process parameters plays a significant role to ensure the quality of the product. This paper presents the optimization aspects of SPIF parameters for titanium denture plate. The optimization strategy is determined by numerical simulation based on Box–Behnken design of experiments and response surface methodology. The Multi-Objective Genetic Algorithm and the Global Optimum Determination by Linking and Interchanging Kindred Evaluators algorithm have been proposed for application to find the optimum solutions. Minimizing the sheet thickness, the final achieved depth and the maximum forming force were considered as objectives. For results evaluation, the denture plate was manufactured using SPIF with the optimum process parameters. The comparison of the final geometry with the target geometry was conducted using an optical measurement system. It is shown that the applied method provides a robust way for the selection of optimum parameters in SPIF.

Similar content being viewed by others

References

Jeswiet J, Micari F, Hirt G, Bramley A, Duflou J, Allwood J (2005) Asymmetric single point incremental forming of sheet metal. CIRP Ann Manuf Technol 54(2):88–114

Arfa H, Bahloul R, BelHadjSalah H (2013) Finite element modelling and experimental investigation of single point incremental forming process of aluminum sheets: influence of process parameters on punch force monitoring and on mechanical and geometrical quality of parts. Int J Mater Form 6(4):483–510

Hirt G, Ames J, Bambach M, Kopp R, Kopp R (2004) Forming strategies and process Modelling for CNC incremental sheet forming. CIRP Ann Manuf Technol 53(1):203–206

Ambrogio G, Filice L, Gagliardi F (2012) Formability of lightweight alloys by hot incremental sheet forming. Mater Des 34:501–508

Bagudanch I, Vives-Mestres M, Sabater M, Garcia-Romeu ML (2016) Polymer incremental sheet forming process: temperature analysis using response surface methodology. Mater Manuf Process 32(1):44–53

Governale A, Lo Franco A, Panzeca A, Fratini L, Micari F (2007) Incremental forming process for the accomplishment of automotive details. Key Eng Mater 344:559–566

Hussain G, Khan HR, Gao L, Hayat N (2013) Guidelines for tool-size selection for single-point incremental forming of an aerospace alloy. Mater Manuf Process 28(3):324–329

Lu B, Ou H, Shi SQ, Long H, Chen J (2016) Titanium based cranial reconstruction using incremental sheet forming. Int J Mater Form 9(3):361–370

Sbayti M, Ghiotti A, Bahloul R, Belhadjsalah H, Bruschi S (2016) Finite element analysis of hot single point incremental forming of hip prostheses, NUMIFORM 2016: The 12th International Conference on Numerical Methods in Industrial Forming Processes, Troyes, France. MATEC Web of Conferences, vol 80

Khan MS, Coenen F, Dixon C (2015) An intelligent process model: predicting springback in single point incremental forming. Int J AdvManuf Technol 76:2071–2082

Isidore BBL, Hussain G, Shamchi SP, Khan WA (2016) Prediction and control of pillow defect in single point incremental forming using numerical simulations. J Mech Sci Technol 30(5):2151–2161

Behera AK, Lauwers B, Duflou JR (2014) Tool path generation for single point incremental forming using intelligent sequencing and multi-step mesh morphing techniques. Int J Mater Form 8(4):517–532

Azaouzi M, Lebaal N (2012) Tool path optimization for single point incremental sheet forming using response surface method. Simul Model Pract Theory 24:49–58

Lu H, Kearney M, Li Y, Liu S, Daniel WJT, Meehan PA (2016) Model predictive control of incremental sheet forming for geometric accuracy improvement. Int J Adv Manuf Technol 82:1781–1794

Lu H, Kearney M, Wang C, Liu S, Meehan PA (2017) Part accuracy improvement in two point incremental forming with a partial die using a model predictive control algorithm. Precis Eng

Ham M, Jeswiet J (2007) Single point incremental forming limits using a Box-Behnken design of experiment. Key Eng Mater 344:629–636

Hussain G, Gao L, Zhang ZY (2008) Formability evaluation of a pure titanium sheet in the cold incremental forming process. Int J Adv Manuf Technol 37(9–10):920–926

Hussain G, Gao L, Hayat N, Dar NU (2010) The formability of annealed and pre-aged AA-2024 sheets in single-point incremental forming. Int J Adv Manuf Technol 46(5–8):543–549

Liu Z, Liu S, Li Y, Meehan PA (2014) Modeling and optimization of surface roughness in incremental sheet forming using a multi-objective function. Mater Manuf Process 29(7):808–818

Bahloul R, Arfa H, BelHadjSalah H (2014) A study on optimal design of process parameters in single point incremental forming of sheet metal by combining Box–Behnken design of experiments, response surface methods and genetic algorithms. Int J Adv Manuf Technol 74(1–4):163–185

Arfa H, Bahloul R, Belhadj Salah H (2015) Multiobjective optimization problem of dieless incremental forming. Key Eng Mater 651–653:1078–1083

Petersen RG (1985) Design and analysis of experiments

Box GEP, Behnken DW (1960) Some new three level designs for the study of variables quantitative. Technometrics 2(4):455–475

Roy K, Kar S, Das RN (2015) A primer on QSAR/QSPR modeling

Zitzler E, Thiele L (1998) Multiobjective optimization using evolutionary algorithms—a comparative case study, Parallel Probl Solving from Nat - PPSN V, pp. 292–301

Oldenhuis R, GODLIKE—a robust single-& multi-objective optimizer—File Exchange—MATLAB Central. [Online]. Available: https://www.mathworks.com/matlabcentral/fileexchange/24838-godlike-a-robust-single---multi-objective-optimizer. [Accessed: 23-Nov-2016]

Chiandussi G, Codegone M, Ferrero S, Varesio FE (2012) Comparison of multi-objective optimization methodologies for engineering applications, vol. 63, no. 5. Elsevier Ltd

Acknowledgements

The authors would like to thank the German Research Foundation DFG for the kind support within the Cluster of Excellence “Integrative Production Technology for High-Wage Countries”. Furthermore, the authors thank the Institute of Metal Forming of RWTH Aachen University for their support in the performance and evaluation of the incremental sheet forming experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sbayti, M., Bahloul, R., BelHadjSalah, H. et al. Optimization techniques applied to single point incremental forming process for biomedical application. Int J Adv Manuf Technol 95, 1789–1804 (2018). https://doi.org/10.1007/s00170-017-1305-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1305-y