Abstract

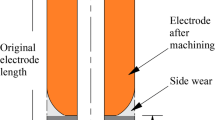

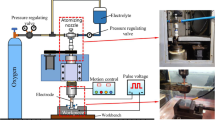

To improve the efficiency of conventional electrical discharge machining (EDM) milling, this study proposes a highly efficient machining method that employs continuous oxygen feeding and fast-moving electrode. High-efficiency machining is achieved by the method of feeding with small thickness, allowing the electrode suspended above the workpiece to reduce short circuit and using a high discharge probability to ignite the workpiece in order to realizing high efficiency machining with great chemical energy released from metal combustion. Comparative tests for conventional EDM milling, EDM ablation milling, and ablation milling by fast-moving electrode were performed in the milling process. In this study, we analyzed the mechanism, machining efficiency, electrode relative wear ratio, and machining quality. The machining efficiency of EDM ablation milling was 6.8 times higher than that of conventional EDM milling, and the relative tool wear ratio was 20% of conventional EDM milling; the machining efficiency of ablation milling by fast-moving electrode can reach 11.2 times higher than that of conventional EDM milling, and the electrode relative wear ratio decreased by 86%.

Similar content being viewed by others

References

Liu ZD (2013) Nontraditional machining. Peking University Press, Beijing

Kunieda M, Yoshida M, Taniguchi N (1997) Electrical discharge machining in gas. CIRP Ann Manuf Technol 46(1):143–146

Li LQ, Wang ZL, Zhao WS (2004) Mechanism analysis of electrical discharge machining in gas. J Harbin Inst Technol 36(3):359–362

Tanimura T, Isuzugawa K, Fujita I, Iwamoto A, Kamitani T (1989) Development of EDM in the mist. Proc ISEM 9:313–316

Gu L, Zhao WS, Zhang ZH, Kang XM (2006) Mist-jetting-ED-milling and its mechanism. Electromachin Mould 2:1–4

Zhang QH, Zhang JH, Deng JX (2002) Ultrasonic vibration electrical discharge machining in gas. J Mater Process Technol 129(1):135–138

Wang XZ, Liu ZD, Xue RY, Tian ZJ, Huang YH (2013) Research on self-mixed oxygen in discharge gap to improve the processing characteristics of titanium alloy electrical discharge machining. Acta Aeronaut Astronaut Sin 34:2419–2426

Wang X, Liu Z, Qiu M, Hui Z, Tian Z, Huang Y (2014) Mechanism of electrical discharge machining ablation. Mater Manuf Process 29(11–12):1367–1373

Fujiki M, Kim GY, Ni J (2011) Gap control for near-dry EDM milling with lead angle. Int J Mach Tools Manuf 51(1):77–83

Fonseca J, Marafona J (2013) The importance of servo reference voltage on multiple discharges. Procedia CIRP 6:416–421

Cao ZL, Liu ZD, Ling JJ, Qiu MB, Wang XZ (2015) Deep-type hole machining by inner jetted aerosol dielectric ablation. Int J Adv Manuf Technol 78(9–12):1989–1998

Acknowledgments

We extend our sincere thanks to all who contributed in the preparation of this manuscript.

Funding

This project is supported by the National Natural Science Foundation of China (Grant Nos. 51675272, 51575271).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, D., Qiu, M., Han, Y. et al. Technology of ablation milling by fast-moving electrode. Int J Adv Manuf Technol 96, 103–109 (2018). https://doi.org/10.1007/s00170-017-1260-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1260-7