Abstract

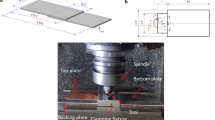

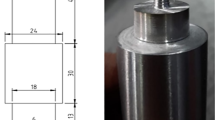

Two different in-process control strategies were developed and compared with the aim to produce AZ31 magnesium alloy joints by friction stir welding on sheet blanks with a non-uniform thickness. To this purpose, sheets with dip or hump zones were welded by either changing the rotational speed or the tool plunging in order to keep constant the value of the vertical force occurring during the welding stage of the process. The influence of the main process parameters on the tool force, the micro- and macromechanical properties, and the joints microstructures in the dip and hump zones were analyzed. The results showed that using the rotational speed change-based approach, the hump zones are subjected to increased heat input with consequent increase of the heat-affected zone extension and average grain size (up to 11 μm). On the contrary, using the tool plunge change-based approach, the weld seam thickness in the dip zones is reduced, resulting in a decreased joint strength, with respect to tool rotation approach, equal to about 18%.

Similar content being viewed by others

References

Merklein M, Johannes M, Lechner M, Kuppert A (2014) A review on tailored blanks—production, applications and evaluation. J Mater Process Technol 214:151–164

Maier V, HausöL T, Schmidt CW, BöHm W, Nguyen H, Merklein M et al (2012) Tailored heat treated accumulative roll bonded aluminum blanks: microstructure and mechanical behavior. Metall Mater Trans A 43:3097–3107

Ryabkov N, Jackel F, van Putten K, Hirt G (2008) Production of blanks with thickness transitions in longitudinal and lateral direction through 3D-strip profile rolling. Int J Mater Form 1:391–394

Meyer A, Wietbrock B, Hirt G (2008) Increasing of the drawing depth using tailor rolled blanks—numerical and experimental analysis. Int J Mach Tools Manuf 48:522–531

Kleiner M, Chatti S, Klaus A (2006) Metal forming techniques for lightweight construction. J Mater Process Technol 177:2–7

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mat Sci Eng R 50:1–78

DebRoy T, Bhadeshia HKDH (2010) Friction stir welding of dissimilar alloys—a perspective. Sci Technol Weld Join 15:266–270

Simoncini M, Forcellese A (2012) Effect of the welding parameters and tool configuration on micro- and macro-mechanical properties of similar and dissimilar FSWed joints in AA5754 and AZ31 thin sheets. Mater Des 41:50–60

Simar A, Avettand-Fènoël MN (2017) State of the art about dissimilar metal friction stir welding. Sci Technol Weld Join 22:389–403

Buffa G, Fratini L, Hua J, Shivpuri R (2006) Friction stir welding of tailored blanks: investigation on process feasibility. CIRP Ann Manuf Technol 55:279–282

Buffa G, Fratini L, Shivpuri R (2008) Finite element studies on friction stir welding processes of tailored blanks. Comput Struct 86:181–189

Silva MB, Skjoedt M, Vilaça P, Bay N, Martins PAF (2009) Single point incremental forming of tailored blanks produced by friction stir welding. J Mater Process Technol 209:811–820

Sheikhi S, Dos Santos JF (2007) Effect of process parameter on mechanical properties of friction stir welded tailored blanks from aluminium alloy 6181-T4. Sci Technol Weld Join 12:370–375

Buffa G, Fratini L, Gnibl T, Wieland M, Merklein M (2012) Process mechanics in friction stir welding of magnesium alloys: experimental and numerical analysis. Key Eng Mater 504–506:735–740

Rai R, De A, Bhadeshia HKDH, DebRoy T (2011) Review: friction stir welding tools. Sci Technol Weld Join 11:325–342

Forcellese A, Gabrielli F, Simoncini M (2012) Mechanical properties and microstructure of joints in AZ31 thin sheets obtained by friction stir welding using “pin” and “pinless” tool configurations. Mater Des 34:219–229

Forcellese A, Simoncini M (2012) Plastic flow behaviour and formability of friction stir welded joints in AZ31 thin sheets obtained using the “pinless” tool configuration. Mater Des 36:123–129

Yang J, Wang D, Xiao BL, Ni DR, Ma ZY (2013) Effects of rotation rates on microstructure, mechanical properties, and fracture behavior of friction stir-welded (FSW) AZ31 magnesium alloy. Metall Mater Trans A 44:517–530

Motalleb-nejad P, Saeid T, Heidarzadeh A, Darzi K, Ashjari M (2014) Effect of tool pin profile on microstructure and mechanical properties of friction stir welded AZ31B magnesium alloy. Mater Des 59:221–226

Selvaraj M, Murali V, Koteswara Rao SR (2013) Mechanism of weld formation during friction stir welding of aluminum alloy. Mater Manuf Process 28:595–600

Trimble D, Monaghan J, O'Donnell GE (2012) Force generation during friction stir welding of AA2024-T3. CIRP Ann Manuf Technol 61:9–12

Forcellese A, Martarelli M, Simoncini M (2016) Effect of process parameters on vertical forces and temperatures developed during friction stir welding of magnesium alloys. Int J Adv Manuf Technol 85:595–604

Su H, CS W, Pittner A, Rethmeier M (2013) Simultaneous measurement of tool torque, traverse force and axial force in friction stir welding. J Manuf Process 15:495–500

Mehta M, Chatterjee K, De A (2013) Monitoring torque and traverse force in friction stir welding from input electrical signatures of driving motors. Sci Technol Weld Join 18:191–197

Zhang H, Lin SB, Wu L, Feng JC, Ma SL (2006) Defects formation procedure and mathematic model for defect free friction stir welding of magnesium alloy. Mater Des 27:805–809

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Buffa, G., Campanella, D., Forcellese, A. et al. In-process control strategies for friction stir welding of AZ31 sheets with non-uniform thickness. Int J Adv Manuf Technol 95, 493–504 (2018). https://doi.org/10.1007/s00170-017-1223-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1223-z