Abstract

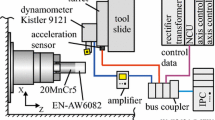

The combination of different materials in one workpiece in order to optimize the workpiece characteristics is a state of the art design method for high-performance components. These workpieces can be made of the most qualified materials according to local requirements. However, during machining of material compounds, the different materials have to be considered. This is due to the specific material properties, cutting characteristics, and chip formation mechanisms. Cutting parameters have to be adapted for each material in order to achieve the demanded workpiece quality and optimal processes in respect of tool life and material removal rate. The focus of this research is the development of an in-process material identification algorithm. Thus, a cylindrical turning process is investigated for friction welded aluminum/steel shafts (EN-AW6082/20MnCr5). A universal monitoring approach is presented which detects the different materials process-parallel. For this purpose, cutting forces and spindle torque are linked with a dexel-based material removal model to determine monitoring parameters. The design of experiment method is used to validate the approach for various process parameters. Cutting speed and feed velocity are adapted for cylindrical turning operations based on the monitoring algorithm. As a result, material-specific cutting parameters are adjusted during the machining in order to optimize the material removal rate. Based on this approach, further process optimization can be implemented, like the improvement of chip formation, while machining hybrid workpieces.

Similar content being viewed by others

References

Behrens BA, Bouguecha A, Frischkorn C, Huskic A, Stakhieva A, Duran D (2016) Tailored forming technology for three dimensional components: approaches to heating and forming. 5th International Conference on Thermomechanical Processing, Italy

Blohm T, Mildebrath M, Stonis M, Langner J, Hassel T, Behrens BA (2017) Investigation of the coating thickness of plasma-transferred arc deposition welded and cross wedge rolled hybrid parts. Prod Eng Res Dev 11:255–263

Boehnke D (2007) Qualitätsorientierte Zerspanung von Parallelverbunden im kontinuierlichen Schnitt. Dissertation, Leibniz Universität Hannover

Ozsváth P, Szmejkál A, Takács J, Eidenhammer M, Obermair F (2006) Development of face milling process for Mg-hybrid (Mg-Al, Mg-sintered steel) Materials. Proceedings of the 7th Int. Conference on Magnesium Alloys and Their Applications, Wiley-VCH Verlag, pp 894–900

Kramer N (2007) In-Process Identification of Material-Properties by Acoustic Emission Signals. Annals of the CIRP, 56/1, pp 331–334

Denkena B, Dahlmann D, Neff T (2016) Autonomous modular process monitoring. 3rd international conference on system-integrated intelligence: new challenges for product and production engineering. Procedia Technol 26, pp 302–308

Denkena B, Koeller M (2013) Simulation based parameterization for process monitoring of machining operations. Procedia CIRP 12:79–84

Tönshoff HK, Denkena B (2013) Basics of cutting and abrasive processes. Springer, Berlin

Acknowledgements

The results presented in this paper were obtained within the German Collaborative Research Centre 1153 “Process chain to produce hybrid high performance components by Tailored Forming” in the subproject B5. The authors would like to thank the German Research Foundation (DFG) for the financial and organizational support of this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Denkena, B., Bergmann, B. & Witt, M. Automatic process parameter adaption for a hybrid workpiece during cylindrical operations. Int J Adv Manuf Technol 95, 311–316 (2018). https://doi.org/10.1007/s00170-017-1196-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1196-y