Abstract

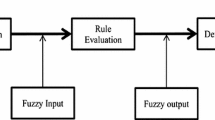

Evaluation of manufacturing equipment performance has been very important in production-related functions such as planning, scheduling, and maintenance. Nevertheless, low accuracy of performance measurements can mislead decision makers. In this study, overall equipment effectiveness (OEE) is considered as a performance indicator of manufacturing equipment. In practice, components of OEE may consist of uncertainty due to manual or semi-automatic measurement systems. As a consequence, true performance of equipment may be masked by the uncertainty of measurements. In this study, two types of uncertainty are considered in production speed and stoppage duration measurements, which are used in calculating OEE components. When the measurements have uncertainty due to use of linguistic terms or some minor stoppages, idling, or speed losses being ignored, fuzzy arithmetic is used as a method to handle uncertainty. In some low accuracy cases, best guess interval estimates of operators may better reflect the state than just providing a point estimate. For such cases, interval arithmetic is used as a method to handle uncertainty. Implementation of the methods are illustrated using two real-world examples and a software is provided for practitioners. Proposed methods help making better informed decisions using OEE under measurement uncertainty of production speed and stoppage durations.

Similar content being viewed by others

References

Assaf SA, Hadidi LA, Hassanain MA, Rezq MF (2015) Performance evaluation and benchmarking for maintenance decision making units at petrochemical corporation using a DEA model. Int J Adv Manuf Technol 76(9–12):1957–1967

Zammori F (2015) Fuzzy overall equipment effectiveness (FOEE): capturing performance fluctuations through LR Fuzzy numbers. Prod Plan Control 26(6):451–466

Sonmez V, Testik MC (2017) Using accurately measured production amounts to obtain calibration curve corrections of production line speed and stoppage duration consisting of measurement errors. Int J Adv Manuf Technol 88(9–12):3257–3263

Sohal A, Olhager J, O’Neill P, Prajogo D (2010) Implementation of OEE—issues and challenges. Competitive and sustainable manufacturing products and services, 1–8

Muchiri P, Pintelon L, Gelders L, Martin H (2011) Development of maintenance function performance measurement framework and indicators. Int J Prod Econ 131(1):295–302

Rößler MP, Abele E (2013). Uncertainty in the analysis of the overall equipment effectiveness on the shop floor. In IOP Conference Series: Materials Science and Engineering. IOP Publishing

Zammori F, Braglia M, Frosolini M (2011) Stochastic overall equipment effectiveness. Int J Prod Res 49(21):6469–6490

Nakajima S (1988) Introduction to TPM: total productive maintenance. Productivity Press, Inc

de Sousa SDT, Nunes EMP, da Silva Lopes I (2013) Uncertainty components in performance measures. In IAENG Transactions on Engineering Technologies (pp. 753–765). Springer Netherlands

Iannone R, Nenni ME (2013) Managing OEE to optimize factory performance. INTECH Open Access Publisher, Rijeka

Muchiri P, Pintelon L (2008) Performance measurement using overall equipment effectiveness (OEE): literature review and practical application discussion. Int J Prod Res 46(13):3517–3535

Nakajima S (1989) TPM development program: implementing total productive maintenance. Productivity Press

Konopka J, Trybula W (1996) Overall equipment effectiveness (OEE) and cost measurement [semiconductor manufacturing]. In Electronics Manufacturing Technology Symposium, 1996, Nineteenth IEEE/CPMT (pp. 137-140). IEEE

Giegling S, Verdini WA, Haymon T, & Konopka, J. (1997) Implementation of overall equipment effectiveness (OEE) system at a semiconductor manufacturer. In Electronics Manufacturing Technology Symposium, 1997, Twenty-First IEEE/CPMT International (pp. 93-98). IEEE

Jeong KY, Phillips DT (2001) Operational efficiency and effectiveness measurement. Int J Oper Prod Manag 21(11):1404–1416

Zhai Y, Jing Z (2017) Applying TPM on production line of Huanwei MATEC Web of Conferences. Vol. 100. EDP Sciences

Lakhdar K (2006). Production planning of biopharmaceutical manufacture (Doctoral dissertation, University of London)

Sonmez V, Testik ÖM (2015) Modeling uncertainty in operators’ statements in measuring the performance of a continuous production line, The 4th International Fuzzy Systems Symposium (FUZZYSS'15), İstanbul/TURKEY, November 5–6

Zimmermann HJ (2010). Fuzzy set theory. Wiley Interdiscip Rev Computat Stat

Kaufmann A, Gupta MM (1988) Fuzzy mathematical models in engineering and management science. Elsevier Science Inc

Mahato SK, Sahoo L, Bhunia AK (2013) Effect of defuzzification methods in redundancy allocation problem with fuzzy valued reliabilities via genetic algorithm. Int J Inf Comput Sci 2(6):106–115

Cheng AC, Chen CJ, Chen CY (2008) A fuzzy multiple criteria comparison of technology forecasting methods for predicting the new materials development. Technol Forecast Soc Chang 75(1):131–141

Moore RE, Kearfott RB, Cloud M J (2009). Introduction to interval analysis. Siam

Hansen E, Walster GW (2003) Global optimization using interval analysis: revised and expanded (264). CRC Press

Dawood, H. (2014) Interval mathematics as a potential weapon against uncertainty. Mathematics of uncertainty modeling in the analysis of engineering and science problems, 1–38

Acknowledgements

We thank the anonymous reviewers for carefully reading the manuscript and for the insightful comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sonmez, V., Testik, M.C. & Testik, O.M. Overall equipment effectiveness when production speeds and stoppage durations are uncertain. Int J Adv Manuf Technol 95, 121–130 (2018). https://doi.org/10.1007/s00170-017-1170-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1170-8