Abstract

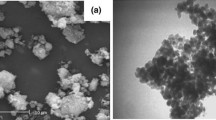

Spark plasma sintering (SPS) is a powder metallurgy technique where uniaxial force and pulsed direct current are employed to perform metallic or ceramic particle consolidation in very short times. The high heating and cooling rates allow to prevent excessive grain growth favoring densification. Spark plasma sintering has been recognized, in the recent past, as a very useful method to produce metal matrix composites characterized by enhanced mechanical and wear properties. Obviously, the materials final properties are strongly related to the reinforcement types and percentages as well as to the processing parameters employed during synthesis. The present paper analyses the effect of microscopic and nanometric alumina particles, blended to pure aluminum in different combinations, on the final properties of metal matrix composites produced via SPS. The SPSed composites were friction stir processed (FSPed), and the processing forces and the heat input in the materials were analyzed. The microstructural and mechanical behavior of the processed materials are shown to be strongly dependent on the starting material properties and on the processing parameters employed during FSP.

Similar content being viewed by others

References

Ghasali E, Alizadeh M, Ebadzadeh T (2016) Mechanical and microstructure comparison between microwave and spark plasma sintering of Al–B4C composite. J Alloys Compd 655:93–98

Ghasali E, Pakseresht A, Rahbari A, Eslami-shahed H, Alizadeh M, Ebadzadeh T (2016) Mechanical properties and microstructure characterization of spark plasma and conventional sintering of Al–SiC–TiC composites. J Alloys Compd 666:366–371

Wolff C, Mercier S, Couque H, Molinari A (2012) Modeling of conventional hot compaction and spark plasma sintering based on modified micromechanical models of porous materials. Mech Mater 49:72–91

Liu Z-F, Zhang Z-H, Lu J-F, Korznikov AV, Korznikova E, Wang F-C (2014) Effect of sintering temperature on microstructures and mechanical properties of spark plasma sintered nanocrystalline aluminum. Mater Des 64:625–630

Munir ZA, Quach DV, Ohyanagi M (2010) Electric current activation of sintering: a review of the pulsed electric current sintering process. J Am Ceram Soc 94(1):1–19

Firestein KL, Corthay S, Steinman AE, Matveev AT, Kovalskii AM, Sukhorukova IV, Golberg D, Shtansky DV (2017) High-strength aluminum-based composites reinforced with BN, AlB2 and AlN particles fabricated via reactive spark plasma sintering of Al-BN powder mixtures. Mater Sci Eng A681:1–9

Babu NK, Kallip K, Leparoux M, AlOgab KA, Maeder X, Rojas Dasilva YA (2016) Influence of microstructure and strengthening mechanism of AlMg5-Al2O3 nanocomposites prepared via spark plasma sintering. Mater Des 95:534–444

Tan Z, Wang L, Xue Y, Zhang P, Cao T, Cheng X (2016) High-entropy alloy particle reinforced Al-based amorphous alloy composite with ultrahigh strength prepared by spark plasma sintering. Mater Des 109:219–226

Mula S, Mondal K, Ghosh S, Pabi SK (2010) Structure and mechanical properties of Al–Ni–Ti amorphous powder consolidated by pressure-less, pressure-assisted and spark plasma sintering. Mater Sci Eng A527:3757–3763

Zhang J, Shi H, Cai M, Liu L, Zhai P (2009) The dynamic properties of SiCp/Al composites fabricated by spark plasma sintering with powders prepared by mechanical alloying process. Mater Sci Eng A527:218–224

Sweet GA, Brochu M, Hexemer RL Jr, Donaldson IW, Bishop DP (2015) Consolidation of aluminum-based metal matrix composites via spark plasma sintering. Mater Sci Eng A648:123–133

Daoush W, Francis A, Lin Y, German R (2015) An exploratory investigation on the in-situ synthesis of SiC/AlN/Al composites by spark plasma sintering. J Alloys Compd 622:458–462

Sadeghian Z, Lotfi B, Enayati MH, Beiss P (2011) Microstructural and mechanical evaluation of Al–TiB2 nanostructured composite fabricated by mechanical alloying. J Alloys Compd 509:7758–7763

Mizuuchi K, Inoue K, Agari Y, Nagaoka T, Sugioka M, Tanaka M, Takeuchi T, Tani J, Kawahara M, Makino Y, Ito M (2012) Processing and thermal properties of Al/AlN composites in continuous solid–liquid co-existent state by spark plasma sintering. Compos Part B 43:1557–1563

Liu ZY, Xiao BL, Wang WG, Ma ZY (2014) Tensile strength and electrical conductivity of carbon nanotube reinforced aluminum matrix composites fabricated by powder metallurgy combined with friction stir processing. J Mater Sci Technol 30(7):649–655

Izadi H, Nolting A, Munro C, Bishop DP, Plucknett KP, Gerlich AP (2013) Friction stir processing of Al/SiC composites fabricated by powder metallurgy. J Mater Proc Technol 213:1900–1907

Guo JF, Liu J, Sun CN, Maleksaeedi S, Bi G, Tan MJ, Wei J (2014) Effects of nano-Al2O3 particle addition on grain structure evolution and mechanical behavior of friction-stir-processed Al. Mater Sci Eng 602:143–149

Elrefaey A, Anders K, Kilian H, Ellermann F, Kulein W (2014) Friction stir welding of extruded powder metallurgy Al alloy. Welding Res 93:451–457

Saeidi M, Behnagh RA, Manafi B, Niko MF, Givi MKB (2017) Study on ultrafine-grained aluminum matrix nanocomposite joint fabricated by friction stir welding. J Mater Des Appl. https://doi.org/10.1177/1464420715572235

Zhang Q, Xiao BL, Wang QZ, Ma ZY (2011) In situ Al3Ti and Al2O3 nanoparticles reinforced Al composites produced by friction stir processing in an Al-TiO2 system. Mater Lett 65:2070–2072

Khodabakhshi F, Ghasemi Yazdabadi H, Kokabi AH, Simchi A (2013) Friction stir welding of a P/M Al-Al2O3 nanocomposite: microstructure and mechanical properties. Mater Sci Eng A585:222–232

Guillon O, Gonzalez-Julian J, Dargatz B, Kessel T, Schierning G, Räthel J, Herrmann M (2014) Field-assisted sintering technology/spark plasma sintering: mechanisms, materials, and technology developments. Adv Eng Mater 16(7):830–849

Hitchcock D, Livingston R, Liebenberg D (2015) Improved understanding of the spark plasma sintering process. J Appl Phys 117(17):174505

Kieback B (2011) A review of spark plasma sintering. Proceedings of the Hagen Symposium, Hagen

Garay J (2010) Current-activated, pressure-assisted densification of materials. Annu Rev Mater Res 40:445–468

Sadeghi B, Shamanian M, Ashrafizadeh F, Cavaliere P, Rizzo A (2017) Influence of Al2O3 nanoparticles on microstructure and strengthening mechanism of al-based nanocomposites produced via spark plasma sintering. J Mater Eng Perform 26(6):2928–2936

Khorshid MT, Jahromi SJ, Moshksar M (2010) Mechanical properties of tri-modal Al matrix composites reinforced by nano- and submicron-sized Al2O3 particulates developed by wet attrition milling and hot extrusion. Mater Des 31(8):3880–3884

Leon C, Rodriguez-Ortiz G, Aguilar-Reyes E (2009) Cold compaction of metal–ceramic powders in the preparation of copper base hybrid materials. Mater Sci Eng A 526:106–112

Mukhopadhyay NK, Paufler P (2006) Micro- and nanoindentation techniques for mechanical characterisation of materials. Int Mater Rev 51(4):209–245

Casati R (2014) Aluminum matrix composites reinforced with alumina nanoparticles. PoliMi Springer Briefs, doi: https://doi.org/10.1007/978-3-319-27732-5_5

Asgharzadeh H, Simchi A, Kim HS (2011) Microstructural features, texture and strengthening mechanisms of nanostructured AA6063 alloy processed by powder metallurgy. Mater Sci Eng A528(12):3981–3989

Deng K, Shi J, Wang C, Wang X, Wu Y, Nie K, Wu K (2012) Microstructure and strengthening mechanism of bimodal size particle reinforced magnesium matrix composite. Compos Part A 43(8):1280–1284

Pelleg J (2012) Mechanical properties of materials. Springer Science & Business Media, Berlin

Dash K, Chaira D, Ray BC (2013) Synthesis and characterization of aluminium–alumina micro- and nano-composites by spark plasma sintering. Mater Res Bull 48:2535–2542

Tjong SC (2013) Processing and deformation characteristics of metals reinforced with ceramic nanoparticles. In: Nanocrystalline materials: their synthesis-structure-property relationships and applications. 269–304

Hirata Y, Fujita H, Shimonosono T (2017) Compressive mechanical properties of partially sintered porous alumina of bimodal particle size system. Ceram Int 43(2):1895–1903

He A, Han Q, Jackson MJ (2008) Nanoparticulate reinforced metal matrix nanocomposites—a review. Int J Nanoparticles 1(4):301–309

Cavaliere P, Campanile G, Panella F, Squillace A (2006) Effect of welding parameters on mechanical and microstructural properties of AA6056 joints produced by friction stir welding. J Mater Proc Technol 180:263–270

Cavaliere P, Squillace A, Panella F (2008) Effect of welding parameters on mechanical and microstructural properties of AA6082 joints produced by friction stir welding. J Mater Proc Technol 200:364–372

Cavaliere P, Cabibbo M, Panella F, Squillace A (2009) 2198 Al–Li plates joined by friction stir welding: mechanical and microstructural behavior. Mater Des 30:3622–3631

Hsu CJ, Chang CY, Kao PW, Ho NJ, Chang CP (2006) Al–Al3Ti nanocomposites produced in situ by friction stir processing. Acta Mater 54:5241–5249

Bodaghi M, Dehghani K (2017) Friction stir welding of AA5052: the effects of SiC nano-particles addition. Int J Adv Manuf Technol 88:2651–2660

McNelley TR, Swaminathan S, Su JQ (2008) Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr Mater 58(5):349–354

Periyasamy P, Mohan B, Balasubramanian V (2012) Effect of heat input on mechanical and metallurgical properties of friction stir welded AA6061-10% SiCp MMCs. J Mater Eng Perform 21(11):2417–2428

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena. Elsevier Science Publisher, Amsterdam

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sadeghi, B., Shamanian, M., Cavaliere, P. et al. Microstructural and mechanical behavior of bimodal reinforced Al-based composites produced by spark plasma sintering and FSP. Int J Adv Manuf Technol 94, 3903–3916 (2018). https://doi.org/10.1007/s00170-017-1144-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1144-x