Abstract

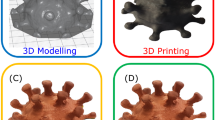

Additive manufacturing (AM) technique can help reduce time, cost, and complexity of the manufactured parts apart from adding functionality. This work explores AM techniques, namely fused deposition modeling (FDM) and PolyJet printing to fabricate a free-form structure with embedded electrical components. Both additive manufacturing technologies are discussed, analyzed, and compared. Another additive manufacturing method is then employed to print the electronic circuitry inside to connect the components. High-resolution X-ray computed tomography (CT) is employed to investigate the dimensional accuracy of the printed parts. This work demonstrates an innovative approach to construct arbitrary 3D objects with fully functional electronic circuits.

Similar content being viewed by others

References

Lindemann C, Jahnke U, Moi M, Koch R (2012) Analyzing product lifecycle costs for a better understanding of cost drivers in additive manufacturing. In: Bourell DL, Crawford RH, Seepersad CC, Beaman JJ, Marcus HL (eds) 23th Annual International Solid Freeform Fabrication Symposium—an Additive Manufacturing Conference., Austin Texas USA, 6th-8th August 2012. pp 177-188

Chua C-K, Yeong W-Y, Leong K-F (2005) Rapid prototyping in tissue engineering: a state-of-the-art report. In: Bartolo PJdS (ed) Proc. 2nd Int. Conf. on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 28 Sep-1 Oct 2005. CRC Press, pp 19-27

Wang S, Lee JM, Yeong WY (2015) Smart hydrogels for 3D bioprinting. Int J Bioprinting 1:1–14

Yap Y, Yeong W (2015) Shape recovery effect of 3D printed polymeric honeycomb: This paper studies the elastic behaviour of different honeycomb structures produced by PolyJet technology. Virtual Phys Prototyp 10(2):91–99

Yeong W, Yap C, Mapar M, Chua C (2013) State-of-the-art review on selective laser melting of ceramics. In: High value manufacturing: advanced research in virtual and rapid prototyping: Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1–5 October, 2013, CRC Press p.65

Olivas R, Salas R, Muse D, MacDonald E, Wicker R, Newton M, Church K Structural electronics through additive manufacturing and micro-dispensing. In: International Symposium on Microelectronics, Raleigh Convention Center, North Carolina, USA, November 2–4 2010. vol 1. International Microelectronics Assembly and Packaging Society, pp 940–946

DeNava E, Navarrete M, Lopes A, Alawneh M, Contreras M, Muse D, Castillo S, MacDonald E, Wicker R (2008) Solid Freeform Fabrication Symposium. In: Three-dimensional off-axis component placement and routing for electronics integration using solid freeform fabrication. The University of Texas at Austin, Austin TX, pp 4–6

Chen L, He Y, Yang Y, Niu S, Ren H (2016) The research status and development trend of additive manufacturing technology. Int J Adv Manuf Technol 9(89):3651–3660

Yap YL, Wang C, Sing SL, Dikshit V, Yeong WY, Wei J (2017) Material jetting additive manufacturing: an experimental study using designed metrological benchmarks. Precision engineering

Moon SK, Tan YE, Hwang J, Yoon Y-J (2014) Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures. Int J Precis Eng Manuf-Green Technol 1(3):223–228

Espalin D, Muse D, MacDonald E, Wicker R (2014) 3D printing multifunctionality: structures with electronics. Int J Adv Manuf Technol 72(5–8):963–978

Willis K, Brockmeyer E, Hudson S, Poupyrev I (2012) Printed optics: 3D printing of embedded optical elements for interactive devices. In: Proceedings of the 25th annual ACM symposium on user interface software and technology, ACM, pp 589–598

Joe Lopes A, MacDonald E, Wicker RB (2012) Integrating stereolithography and direct print technologies for 3D structural electronics fabrication. Rapid Prototyp J 18(2):129–143

MacDonald E, Salas R, Espalin D, Perez M, Aguilera E, Muse D, Wicker RB (2014) 3D printing for the rapid prototyping of structural electronics. Access, IEEE 2:234–242

Periard D, Malone E, Lipson H (2007) Printing embedded circuits. In: 18th Solid Freeform Fabrication Symposium, Austin TX, Citeseer, pp 6–8

Agarwala S, Yeong WY (2016) 3D printed electronics tracks for bio-integrated free-form devices. In: Chua C-K (ed) 2nd International Conference on Progress in Additive Manufacturing (Pro-AM), Singapore, May 2016. pp 313–316

Zhang Z, Zhu W (2015) Controllable synthesis and sintering of silver nanoparticles for inkjet-printed flexible electronics. J Alloys Compd 649:687–693

Chen S, Su M, Zhang C, Gao M, Bao B, Yang Q, Su B, Song Y (2015) Fabrication of nanoscale circuits on inkjet-printing patterned substrates. Adv Mater 27(26):3928–3933

Goh GL, Ma J, ChuaKLF, Shweta A, Yeong WY, ZhangYP (2016) Inkjetprinted patch antenna emitter for wireless communication application. Virtual and Physical Prototyping 11(4):289-294

Lewis JA, Ahn BY (2015) Device fabrication: three-dimensional printed electronics. Nature 518(7537):42–43

Muth JT, Vogt DM, Truby RL, Mengüç Y, Kolesky DB, Wood RJ, Lewis JA (2014) Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv Mater 26(36):6307–6312

Lessing J, Glavan AC, Walker SB, Keplinger C, Lewis JA, Whitesides GM (2014) Inkjet printing of conductive inks with high lateral resolution on omniphobic “RF paper” for paper-based electronics and MEMS. Adv Mater 26(27):4677–4682

Agarwala S, Kevin M, Wong A, Peh C, Thavasi V, Ho G (2010) Mesophase ordering of TiO2 film with high surface area and strong light harvesting for dye-sensitized solar cell. ACS Appl Mater Interfaces 2(7):1844–1850

Agarwala S, Lim Z, Nicholson E, Ho G (2012) Probing the morphology-device relation of Fe2O3 nanostructures towards photovoltaic and sensing applications. Nano 4(1):194–205

Agarwala S, Ong W, Ho G (2013) Tailoring the porosity of 3D tin oxide nanostructures using urea for sensing and photovoltaic applications. Sci Adv Mater 5(10):1418–1426

Nancharaiah T, d Ranga Raju VR, Raju R (2010) An experimental investigation on surface quality and dimensional accuracy of FDM components

Sood AK, Ohdar R, Mahapatra S (2009) Improving dimensional accuracy of fused deposition modelling processed part using grey Taguchi method. Mater Des 30(10):4243–4252

Huang X, Ye C, Wu S, Guo K, Mo J (2009) Sloping wall structure support generation for fused deposition modeling. Int J Adv Manuf Technol 42(11–12):1074

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Electronic supplementary material

Figure S1

(a) Image of (a) silver nanoparticle and (b) carbon paint ink on PolyJet printed substrate. Optical microscope images for (c) silver nanoparticle and (d) carbon paint printed track lines (PPTX 10559 kb).

Rights and permissions

About this article

Cite this article

Goh, G. ., Agarwala, S., Goh, G.D. et al. Additively manufactured multi-material free-form structure with printed electronics. Int J Adv Manuf Technol 94, 1309–1316 (2018). https://doi.org/10.1007/s00170-017-0972-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0972-z