Abstract

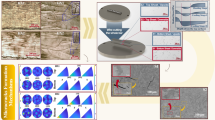

Electroless nickel phosphide (Ni–P) plating is used to fabricate microgrooves for precision glass molding (PGM) due to its excellent mechanical properties as a mold material. To achieve a high-quality microgroove fabrication, the causes of the machining defect, like burrs on the mold surface during the microgrooving of amorphous nickel phosphide (a-Ni–P) by single-point diamond cutting, are investigated. We find that the burrs can be eliminated by increasing the brittleness of a-Ni–P, so the brittleness enhancement of the material is conducted by crystallization. Then, the machined surface and the chip morphology during cutting crystalline nickel phosphide (c-Ni–P) are analyzed and compared with that during a-Ni–P microgrooving. Through this innovation, the surface quality of the microgroove is improved with minimized burrs.

Similar content being viewed by others

References

Yan JW, Oowada T, Zhou TF, Kuriyagawa T (2009) Precision machining of microstructureson electroless-plated NiP surface for molding glass components. J Mater Process Technol 209:4802–4808

Yan JY, Zhang ZY, Kuriyagawa T, Gonda H (2010) Fabricating micro-structured surface by using single-crystalline diamond endmill. Int J Adv Manuf Technol 51:957–964

Chao CH, Shen SC, Wu JR (2009) Fabrication of 3-D submicron glass structures by FIB. J Mater Process Technol 18:878–885

Fang FZ, Chen L (2000) Ultra-precision cutting for ZKN7 glass. Ann Manuf Technol 49:17–20

Palanikumar K (2008) Application of Taguchi and response surface methodologies for surface roughness in machining glass fiber reinforced plastics by PCD tooling. Int J Adv Manuf Technol 36:19–27

Arif M, Rahman M, San W (2013) A study on the effect of tool-edge radius on critical machining characteristics in ultra-precision milling of tungsten carbide. Int J Adv Manuf Technol 67:1257–1265

Brenner A, Riddell G, Res J (1946) Natl Bur Stand The 31th Annu. Tech. Conf. Proc.-Am. Electroplat. Soc.33 37:31–34

Casstevens JM, Daugherty CE (1978) Diamond turning of optical surfaces on electroless nickel. SPIE 159 Precision Machining of Optics 109–113

Hitchiner MP, Wilks J (1984) Factors affecting chemical wear during machining. Wear 93:63–80

Davies MA., Evans CJ, Patterson SR (2003) Application of precision diamond machining to the manufacture of micro-photonics components. In: Proc. of SPIE Lithographic and Micromachining Techniques for Optical Component Fabrication II, vol 5183. SPIE, Bellingham, pp 94–108

Zhoua TF, Yan JW, Liang ZQ, Wang XB (2015) Development of polycrystalline Ni–P mold by heat treatment for glass microgroove forming. Precis Eng 39:25–30

Fang FZ, Liu YC (2004) On minimum exit-burr in micro cutting. J Micromech Microeng 14(7):984–988

Le D, Lee JM, Kim SJ (2010) Burr analysis in microgrooving. Int J Adv Manuf Technol 50(5–8):569–577

Keong NW, Kumar AS, Rahman M (2012) A novel method for layered tool path generation in the fast tool servo diamond turning of noncircular microstructural surfaces. Proc IMechE Part B J Eng Manuf 227(2):210–219

Li GH, Xu ZW, Fang FZ (2013) Micro cutting of V-shaped cylindrical grating template for roller nanoimprint. J Mater Process Tech 213(6):895–904

Zong WJ, Li ZQ, Zhang L, Liang YC, Sun T, An CH, Zhang JF, Zhou L, Wang J (2013) Finite element simulation of diamond tool geometries affecting the 3D surface topography in fly cutting of KDP crystals. Int J Adv Manuf Technol 68:1927–1936

Chen WQ, Liu HT, Sun YZ, Yang K, Zhang JY (2017) A novel simulation method for interaction of machining process and machine tool structure. Int J Adv Manuf Technol 88:3467–3474

Shen YF, Xue WY, Liu ZY, Zuo L (2010) Nanoscratching deformation and fracture toughness of electroless Ni–P coatings. Surf Coat Technol 205:632–640

Liu Y, Zhao WX, Zhou TF, Xin L, Wang XB (2017) Microgroove machining on crystalline nickel phosphide plating by single-point diamond cutting. Int J Adv Manuf Technol. doi:10.1007/s00170-016-9720-z

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Zhao, W., Zhou, T. et al. Surface defect elimination in microgrooving of electroless nickel phosphide plating layer by brittleness enhancement. Int J Adv Manuf Technol 94, 1327–1333 (2018). https://doi.org/10.1007/s00170-017-0940-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0940-7