Abstract

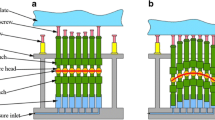

In order to solve the folded problem in multi-point forming with symmetric punches (SMPF), a new process of multi-point forming with asymmetric punches (AMPF) is proposed in this paper. Experiment and numerical simulation were both used to elaborately analyze the problem of fold. The deformation behaviors of cylindrical surface, spherical surface, and sail surface in two processes were investigated. The characteristics of shape precision of the sheet metal were obtained under different forming parameters. Then, the stress and strain distribution of the cylindrical surface is obtained by numerical simulations. Finally, the mechanisms of folded generation and suppression were revealed by process analysis. It is shown that the surface quality and the forming precision of the workpiece formed by AMPF are improved by AMPF. Besides, the stress fluctuation during the forming process is obviously reduced and the uniformity of stress and strain after forming is enhanced. In addition, under the same loading condition, the average shape error of the cylindrical surface decreases by 17.6%, the stress extremum difference decreases by 5.7%, and the strain extremum difference decreases by 4.3%. The above research indicates that AMPF has a good application prospect in sheet metal forming.

Similar content being viewed by others

References

Liu CG, Li J, Dong YN, Zhang XG, Yue T (2017) Fracture prediction in the forming of aircraft Al stiffeners using multi-point dies. Int J Adv Manuf Technol 90(9):3109–3118

Heo SC, Seo YH, Ku TW, Kang BS (2010) A study on thick plate forming using flexible forming process and its application to a simply curved plate. Int J Adv Manuf Technol 51(1):103–115

Liu CG, Li MZ, Fu WZ (2008) Principles and apparatus of multi-point forming for sheet metal. Int J Adv Manuf Technol 35(11):1227–1233

Chen JJ, Li MZ, Liu W, Wang CT (2005) Sectional multipoint forming technology for large-size sheet metal. Int J Adv Manuf Technol 25(9):935–939

Tan FX, Li MZ, Cai ZY, Li XJ (2009) Formability analysis on the process of multi-point forming for titanium alloy retiary sheet. Int J Adv Manuf Technol 41(11):1059–1065

Abebe M, Park JW, Kang BS (2016) Reliability-based robust process optimization of multi-point dieless forming for product defect reduction. Int J Adv Manuf Technol. doi:10.1007/s00170-016-9172-5

Lu J, Zhou K (2011) Multi-point location theory method and application for flexible tooling system in aircraft manufacturing. Int J Adv Manuf Technol 54(5):729–736

Liu CG, Li J, Dong YN, Zhang XG, Yue T (2016) Fracture prediction in the forming of aircraft Al stiffeners using multi-point dies. Int J Adv Manuf Technol. doi:10.1007/s00170-016-9634-9

Liu Y, Li M, Ju F (2016) Research on the process of flexible blank holder in multi-point forming for spherical surface parts. Int J Adv Manuf Technol. doi:10.1007/s00170-016-9198-8

Cai ZY, Wang SH, Li MZ (2008) Numerical investigation of multi-point forming process for sheet metal wrinkling dimpling and springback. Int J Adv Manuf Technol 37(9):927–936

Walczyk DF, Hardt DE (1998) Design and analysis of reconfigurable discrete dies for sheet metal forming. J Manuf Syst 17(6):436–454

Quan GZ, Ku TW, Kang BS (2011) Improvement of formability for multi-point bending process of AZ31B sheet material using elastic cushion. Int J Precis Eng Man 12(6):1023–1030

Zhang Q, Wang ZR, Dean TA (2008) The mechanics of multi-point sandwich forming. Int J Mach Tool Manu 48(12):1495–1503

Lu B, Zhang H, Xu DK, Chen J (2014) A hybrid flexible sheet forming approach towards uniform thickness distribution. Int Conf Manuf Light Components 18(18):244–249

Gong XP, Li MZ, Lu QP, Peng ZQ (2012) Research on continuous multi-point forming method for rotary surface. J Mater Process Tech 212(1):227–236

Hua JF, Yong HU, Wang CF, Zhou YQ (2011) No-pair dins forming technology for complex curved surface of ship hull plate. Ship Engineering 33(2):63–66 (in Chinese)

Sun G, Li MZ, Yan XP, Zhong PP (2007) Study of blank-holder technology on multi-point forming of thin sheet metal. J Mater Process Tech 187-188(12):517–520

Xing J, Li MZ, Chen YY, Wang BL, Yang Z (2016) Effect of the arrangement of the punch units in multi-point stretch forming process. Int J Adv Manuf Technol. doi:10.1007/s00170-016-8367-0

Li MZ, Cai ZY, Sui Z, Yan QG (2002) Multi-point forming technology for sheet metal. J Mater Process Tech 129(1–3):333–338

Selmi N, Belhadjsalah H (2013) Experimental implementation of the multipoint hydroforming process. In: Proceedings of the fifth international conference design and modeling of mechanical systems, pp. 477–484

Luo Y, Yang W, Liu Z, Wang Y, Du R (2016) Numerical simulation and experimental study on cyclic multi-point incremental forming process. Int J Adv Manuf Technol 85(5):1249–1259

Liu ZW, Li MZ, Han QG (2012) Multi-point forming with wrinkle resistance function and it’s forming accuracy. Journal of Mechanical Engineering 48(12):56–62 (in Chinese)

Jia BB, Wang WW (2016) New process of multi-point forming with individually controlled force-displacement and mechanism of inhibiting springback. Int J Adv Manuf Technol. doi:10.1007/s00170-016-9709-7

Cai ZY, Wang SH, Xu XD, Li MZ (2009) Numerical simulation for the multi-point stretch forming process of sheet metal. J Mater Process Tech 209(1):396–407

Abebe M, Lee K, Kang BS (2016) Surrogate-based multi-point forming process optimization for dimpling and wrinkling reduction. Int J Adv Manuf Technol 85(1):391–403

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, B., Wang, W. Deformation behavior of curved shells in multi-point forming with asymmetric punches. Int J Adv Manuf Technol 93, 3981–3990 (2017). https://doi.org/10.1007/s00170-017-0825-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0825-9