Abstract

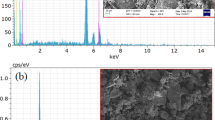

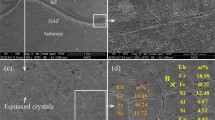

The Fe–Cr–Ni–C alloy coatings with different phases have been prepared by plasma cladding technique on high manganese austenitic steel preheated with different temperatures. The effect of the phase composition on crack formation, residual stress, and micro-hardness of Fe–Cr–Ni–C alloy coatings was investigated by scanning electron microscopy (SEM) with energy-dispersive spectrum (EDS), micro-hardness tester, infrared thermal imager, and residual stress tester. The results show that for Fe-based coating deposited on the substrate non-preheated, the transverse and perpendicular cracks are generated after the end of cladding, which belongs to transcrystalline fracture. The Fe–Cr–Ni–C alloy coatings are composed of the solid solution of austenitic and fishbone-like eutectic carbide, which was mainly (Cr, Fe)7C3. As the preheating temperature of substrate is 350 °C, granular metallic carbides with the diameter 1 μm are precipitated at grain boundaries and no cracks formed. The carbide phases are mainly (Cr, Fe)7C3 and (Cr, Fe)23C6 in cladding coatings. With the decreased rate of cooling, carbide precipitation phase changed from metastable (Cr, Fe)7C3 to stable (Cr, Fe)23C6 phase. The precipitation stable carbide phase has significance to prevent the formation of cracks and improves the micro-hardness of the Fe-based coating on the substrate preheated to 350 °C. The residual stress of specimen with substrates of non-preheating and preheating 250 and 350 °C is 234.2, 267.3, and 300.6 MPa, respectively. The maximum value of micro-hardness of coating with substrates of non-preheating is 986.1 HV, which is about six times than that of substrate.

Similar content being viewed by others

References

Zwilsky KM, LAMET, Aggen G, Akstens WF et al (1993) ASM handbook. Properties and selection: irons, steels, and high-performance alloys. ASM international, Ohio

Shur EA, Kleshcheva II, Bychkova NY (1989) Application of knurling for the preoperational strengthening of objects made of high manganese steel. Met Sci Heat Treat 31(5):384–386

Zhang L (2008) Effect of niobium on the microstructure and wear resistance of iron-based alloy coating produced by plasma cladding. Mater Sci Eng A 490(1–2):57–61

Moghaddam EG, Varahram N, Davami P (2012) On the comparison of microstructural characteristics and mechanical properties of high-vanadium austenitic manganese steels with the Hadfield steel. Mater Sci Eng A 532:260–266

Nakada N, Mizutani K, Tsuchiyama T, Takaki S (2014) Difference in transformation behavior between ferrite and austenite formations in medium manganese steel. Acta Mater 65:251–258

Schymura M, Fischer A (2014) Metallurgical aspects on the fatigue of solution-annealed austenitic high interstitial steels. Int J Fatigue 61:1–9

Lu F, Li HQ, Ji Q (2011) Characteristics of the functionally graded coating fabricated by plasma transferred arc centrifugal cladding. Surf Coat Tech 205:4441–4446

Wang FJ, Mao HD, Zhang DW, Zhao XY (2009) The crack control during laser cladding by adding the stainless steel net in the coating. Appl Surf Sci 255:8846–8854

Fallah V, Alimardani M, Corbin SF, Khajepour (2010) A impact of localized surface preheating on the microstructure and crack formation in laser direct deposition of Stellite1 on AISI 4340 steel. App Surf Sci 257:1716–1723

Zhang K, Wang SJ, Liu JW, Long RS (2014) Effects of substrate preheating on the thin-wall part built by laser metal deposition shaping. App Surf Sci 317:839–855

Daniel C, Christien F, Le Gall R (2007) Intergranular fatigue cracking enhanced by impurity segregation. Mater Sci Forum 539-543:2137–2142

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, Y., Wan, J., Yuan, L. et al. Influence of the phase composition and microstructure of plasma cladding Fe-Cr-Ni-C alloy coating on residual stress and crack formation. Int J Adv Manuf Technol 96, 1607–1613 (2018). https://doi.org/10.1007/s00170-017-0765-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0765-4