Abstract

The present study deals with the effect of the heat input on the tensile properties of AH-40 fatigue crack arrester steel (FCA). The joining process was implemented by the use of the robotic metal-cored arc welding technique with five heat input levels (0.5, 1.0, 1.5, 2.0, and 2.5 kJ/mm), which led to different microstructural and mechanical properties of the weldments. Initially, the microstructural characterization of the welds was carried out, followed by the measurement of the microhardness distribution, while appropriate coupons extracted from the welds were tested under uniaxial tensile loading and examined fractographically. The experimental results of the analysis correlate the selected operational parameters with the properties of the welds and principally with their tensile performance. Consequently, the obtained data result in the optimization of the structure, leading to the conclusion that the optimum heat input should be approximately 1.0 kJ/mm when AH-40 FCA steel plates of 13-mm thickness are welded.

Similar content being viewed by others

References

ASM International (2004) Tensile testing

Lee JH, Park SH, Kwon HS et al (2014) Laser, tungsten inert gas, and metal active gas welding of DP780 steel: comparison of hardness, tensile properties and fatigue resistance. Mater Des 64:559–565. doi:10.1016/j.matdes.2014.07.065

Zuhailawati H, Jamaluddin MA, Seman AA, Ismail S (2016) Welding investigation and prediction of tensile strength of 304 stainless steel sheet metal joint by response surface methodology. Procedia Chem 19:217–221. doi:10.1016/j.proche.2016.03.096

Mishra RR, Tiwari VK, Rajesha S (2014) A study of tensile strength of MIG and TIG welded dissimilar joint of mild steel and stainless steel. Int J Adv Mater Sci Eng 3:23–32. doi:10.14810/ijamse.2014.3203

Ragu Nathan S, Balasubramanian V, Malarvizhi S, Rao AG (2015) Effect of welding processes on mechanical and microstructural characteristics of high strength low alloy naval grade steel joints. Def Technol 11:308–317. doi:10.1016/j.dt.2015.06.001

BS EN ISO 1011–1 (2009) Welding recommendations for welding of metallic materials. Part 1: general guidance for arc welding

Hu J, Du L-X, Xie H et al (2014) Microstructure and mechanical properties of TMCP heavy plate microalloyed steel. Mater Sci Eng A 607:122–131. doi:10.1016/j.msea.2014.03.133

Yakubtsov IA, Poruks P, Boyd JD (2008) Microstructure and mechanical properties of bainitic low carbon high strength plate steels. Mater Sci Eng A 480:109–116. doi:10.1016/j.msea.2007.06.069

Nishioka K, Ichikawa K (2012) Progress in thermomechanical control of steel plates and their commercialization. Sci Technol Adv Mater 13:23001. doi:10.1088/1468-6996/13/2/023001

Ohmori A, Nakagawa K, Murota Y (2015) High performance 590 N/mm2 class thermo-mechanical control process ( TMCP ) steel plate“HBL TM440” for building structure

Imai S (2002) General properties of TMCP steels. In: Int. Offshore Polar Eng. Conf. The International Society of Offshore and Polar Engineers, Kitakyushu, Japan, pp 392–396

Alipooramirabad H, Ghomashchi R, Paradowska A, Reid M (2016) Residual stress- microstructure- mechanical property interrelationships in multipass HSLA steel welds. J Mater Process Technol 231:456–467. doi:10.1016/j.jmatprotec.2016.01.020

Chen Y, Yong-Yi W (2007) Microstructure modeling of HAZ softening in microalloyed high strength linepipe steels. Proc. Sixt. Int. Offshore Polar Eng. Conf

Minagawa M, Funatsu Y, Ishida K, Shiro I (2004) 390 MPa yield strength steel plate for large heat-input welding for large container ships

Zondi C (2014) Factors that affect welding-induced residual stress and distortions in pressure vessel steels and their mitigation techniques: a review. J Press Vessel Technol 136

TWI Is there a restriction on the heat input that can be used for the welding of TMCP (thermo-mechanically controlled processed) steels—if so, why? In: http://www.twi-global.com/

Pirinen M (2013) The effects of welding heat input on the usability of high strength. Lappeenranta University of Technology

Ghazvinloo HR, Honarbakhsh Raouf A (2010) Effect of gas-shielded flux cored arc welding parameters on weld width and tensile properties of weld metal in a low carbon steel. J. Appl. Sci

Kannan T, Yoganandh J (2010) Effect of process parameters on clad bead geometry and its shape relationships of stainless steel claddings deposited by GMAW. Int J Adv Manuf Technol 47:1083–1095. doi:10.1007/s00170-009-2226-1

Palani PK, Murugan N (2007) Modeling and simulation of wire feed rate for steady current and pulsed current gas metal arc welding using 317L flux cored wire. Int J Adv Manuf Technol 34:1111–1119. doi:10.1007/s00170-006-0678-0

Konda N, Inami A, Arimochi K, et al (2010) A proposed design S-N curve for steels with improved fatigue resistance (FCA steels). In: 11th Int. Symp. Pract. Des. Ships Other Float. Struct. pp 1233–1242

Konda N, Arimochi K, Hirota K, et al (2003) Development of structural steel with superior resistance against fatigue crack growth. In: 22nd Int. Conf. Offshore Mech. Arct. Eng. pp 1–10

Kazasidis M, Chionopoulos S, Pantelis D (2015) Experimental investigation of FCAW-G weldments of HSLA AH-40 FCA steel, used in marine applications. NAV 2015 18th Int Conf Ships Shipp Res

ISO 17632:2015 Welding consumables—tubular cored electrodes for metal arc welding with and without a gas shield of non-alloy and fine grain steels—classification

BS EN ISO 15614–1 (2012) Specification and qualification of welding procedures for metallic materials. Part 1: arc and gas welding of steels and arc welding of nickel and nickel alloys

Peng Y, Wang A, Xiao H, Tian Z (2012) Effect of interpass temperature on microstructure and mechanical properties of weld metal of 690 MPa HSLA steel. Mater Sci Forum. doi:10.4028/www.scientific.net/MSF.706-709.2246

Scotti A, Ponomarev V, Lucas W (2012) A scientific application oriented classification for metal transfer modes in GMA welding. J Mater Process Technol 212:1406–1413. doi:10.1016/j.jmatprotec.2012.01.021

Lincoln electric (2010) Gas metal arc welding. Product and Procedure Selection

Bhadeshia H, Honeycombe R (2006) Steels: microstructure and properties. doi:10.1016/0378-3804(82)90037-7

Xue XH, Shan YY, Zheng L, Lou SN (2006) Microstructural characteristic of low carbon microalloyed steels produced by thermo-mechanical controlled process. Mater Sci Eng A 438–440:285–287. doi:10.1016/j.msea.2006.02.064

Eroğlu M, Aksoy M, Orhan N (1999) Effect of coarse initial grain size on microstructure and mechanical properties of weld metal and HAZ of a low carbon steel. Mater Sci Eng A 269:59–66. doi:10.1016/S0921-5093(99)00137-9

Kong X, Lan L (2014) Optimization of mechanical properties of low carbon bainitic steel using TMCP and accelerated cooling. Procedia Eng 81:114–119. doi:10.1016/j.proeng.2014.09.136

Wang J, Liu Y, Wang K, Liu Y (2015) Research on acicular ferrite nucleation induced by inclusions in pipeline steel welding heat affected zone. In: Int. Conf. Mater. Sci. Appl. (ICMSA 2015) res. pp 902–905

Liu Z, Kobayashi Y, Yin F et al (2007) Nucleation of acicular ferrite on sulfide inclusion during rapid solidification of low carbon steel. ISIJ Int 47:1781–1788. doi:10.2355/isijinternational.47.1781

Fattahi M, Nabhani N, Hosseini M et al (2013) Effect of Ti-containing inclusions on the nucleation of acicular ferrite and mechanical properties of multipass weld metals. Micron 45:107–114. doi:10.1016/j.micron.2012.11.004

Nuruddin I (2012) Effect of welding thermal cycles on the heat affected zone microstructure and toughness of multi-pass welded pipeline steels. Cranfield University

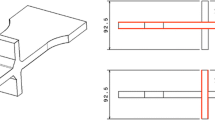

EN ISO 4136: 2012 Destructive tests on welds in metallic materials—transverse tensile test

Yuan WJ, Zhang ZL, Su YJ et al (2012) Influence of specimen thickness with rectangular cross-section on the tensile properties of structural steels. Mater Sci Eng A 532:601–605. doi:10.1016/j.msea.2011.11.021

Lehto P, Remes H, Saukkonen T et al (2014) Influence of grain size distribution on the Hall-Petch relationship of welded structural steel. Mater Sci Eng A 592:28–39. doi:10.1016/j.msea.2013.10.094

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kazasidis, M.E., Pantelis, D.I. The effect of the heat input energy on the tensile properties of the AH-40 fatigue crack arrester steel, welded by the use of the robotic metal-cored arc welding technique. Int J Adv Manuf Technol 93, 3967–3980 (2017). https://doi.org/10.1007/s00170-017-0761-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0761-8