Abstract

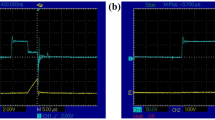

The mechanism of material removal through cool electrode electrical discharge machining (EDM) was investigated in this study by using single pulse discharge method. The influence of electrode temperature on the electric erosion pit morphology on the surface of the electrode and workpiece was analyzed. Finite element simulation was conducted on the temperature field between the electrode and workpiece under different electrode temperatures, and the simulation results were verified through a single pulse experiment. Under the same single pulse discharge parameters, when the electrode temperature was −20, 20, and 60 °C, the electric erosion pit diameter on the electrode surface increased to 290, 350, and 403 μm, respectively; the change in electric erosion pit diameter on the workpiece surface was small, and the corresponding values were 690, 705, and 718 μm. However, the bulge of the electric erosion pit on the surface of the workpiece became increasingly obvious, and the surface became unsmooth. The results of the single pulse experiment and the finite element simulation were identical. A comparative experiment involving the machining of Ti-6Al-4V titanium alloy was conducted with cool electrode and conventional EDM. Electrode wear, surface roughness, and machining efficiency were analyzed. Compared with that in conventional EDM, electrode wear decreased by 24.5%, the material removal rate increased by 14.16%, and surface roughness decreased by 14.14% in cool electrode EDM. Reducing the electrode temperature changed the electric erosion pit morphology on the electrode and workpiece surface, reduced electrode wear, improved surface processing quality, and increased processing efficiency.

Similar content being viewed by others

References

Liu ZD, Gao CS (2011) Electrical discharge machining technology and application. National Defence Industry Press, Beijing, pp 13–26

Zhang M, Zhang Q, Dou L, Liu Q, Dong C (2016) Comparisons of single pulse discharge crater geometries in EDM and EAM. J Manuf Process 22:74–81

Macedo FTB, Wiessner M, Hollenstein C, Kuster F, Wegener K (2016) Dependence of crater formation in dry EDM on electrical breakdown mechanism. Procedia CIRP 42:161–166

Schulze HP, Herms R, Juhr H, Schaetzing W, Wollenberg G (2004) Comparison of measured and simulated crater morphology for EDM. J Mater Process Technol 149(1–3):316–322

Gill SS, Singh J (2010) Effect of deep cryogenic treatment on machinability of titanium alloy (Ti-6246) in electric discharge drilling. Mater Manuf Process 25(6):378–385

Abdulkareem S, Khan AA, Konneh M (2010) Cooling effect on electrode and process parameters in EDM. Mater Manuf Process 25(6):462–466

Abdulkareem S, Khan AA, Konneh M (2009) Reducing electrode wear ratio using cryogenic cooling during electrical discharge machining. Int J Adv Manuf Technol 45(11–12):1146–1151

Hui ZG, Liu ZD, Qiu MB, Wang XZ, Cao ZL (2014) Discharge characteristics of cool electrode in EDM based on monopulse discharge. Int J Adv Manuf Technol 75(5–8):731–738

Tlili A, Ghanem F, Ben Salah N (2015) A contribution in EDM simulation field. Int J Adv Manuf Technol 79(5–8):921–935

Ben Salah N, Ghanem F, Ben Atig K (2008) Thermal and mechanical numerical modelling of electric discharge machining process. Commun Numer Methods Eng 24(12):2021–2034

Xie L, Tang GF (2008) The development and application of semiconductor refrigeration technology. Contamination Control & Air-conditioning Technology 1:68–71

Qiu MB, Huang YH, Liu ZD, Tian ZJ, Wang W (2009) Study on energy distribution at electrode of electrical discharge machining based on photon emission. Acta Opt Sin 09:2546–2551

Mingbo Q (2010) Research on electrical discharged machining of semiconductor crystal materials. Nanjing University of Aeronautics and Astronautics

Li MH (1989) Theoretical basic of EDM. National Defense Industry Press, Beijing

Pandey PC, Jilani ST (1986) Plasma channel growth and the resolidified layer in edm. Precis Eng 8(2):104–110

Van Dijck FS, Dutré WL (2002) Heat conduction model for the calculation of the volume of molten metal in electric discharges. Food Science & Technology International Tokyo 7(6):559–584

Hui Z, Liu Z, Cao Z, Qiu M (2016) Effect of cryogenic cooling of tool electrode on machining titanium alloy (Ti-6Al-4V) during EDM. Materials & Manufacturing Processes 31(4):475–482

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chao, Z., Mingbo, Q., Jing, Y. et al. Influence of electrode temperature on electric erosion pit morphology during cool electrode EDM. Int J Adv Manuf Technol 93, 2173–2181 (2017). https://doi.org/10.1007/s00170-017-0672-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0672-8