Abstract

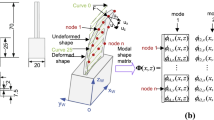

The surface waviness of blade surfaces in numerically controlled (NC) milling processes directly affects the mechanical behavior of the blade. To research the mechanism of surface waviness formation, this study utilizes wavelet analysis in investigating the measured results of surface profile. Firstly, the experiment on a #45 steel cantilever blade was performed on an NC milling machine and the vibrational signals during the milling process were analyzed by fast Fourier transform. Secondly, the first-order natural frequencies of the machine-tool system and the machine-workpiece system were obtained by modal test based on DWESOFT and simulation based on ANSYS. Thirdly, the selected optimal wavelet was applied to decompose and reconstruct each layer of the blade surface contour signal based on MATLAB. Finally, the frequency information of the wavelet, the frequency information of the milling vibration signals, and the first-order natural frequencies of the systems were compared. The maximum of the amplitude value of the milling vibration signals corresponds to the frequency 161.1 Hz, which is equivalent to the excitation frequency of the teeth by calculating and the frequency of the maximum amplitude of the second-layer profile by wavelet analysis. The modal analysis showed that the first-order natural frequencies of the machine-tool system in the x and y directions and the machine-workpiece system are 737.3, 668.9, and 542.0 Hz, respectively, which are far away from the frequencies the maximum amplitude of the each layer profile obtained by wavelet analysis. The results showed that surface waviness is caused by forced vibration in thin-blade NC milling, rather than self-excited vibration.

Similar content being viewed by others

References

Lin XJ, Wang WH, Shan CW (2009) Research on the new manufacturing process of aeroengine blade. Aviat Precis Manufac Technol 45(05):262–274

Pessoles X, Tournier C (2009) Automatic polishing process of plastic injection molds on a 5-axis milling center. J Mater Process Technol 209(209):3665–3673

Tsai MJ, Huang JF, Kao WL (2009) Robotic polishing of precision molds with uniform material removal control. Int J Mach Tool Manu 49(11):885–895

Huang Z, Huang Y (2009) The development of cutter location algorithm for the 6-axis simultaneous CNC abrasive belt grinding complex surface. Key Eng Mater 416(9):375–380

Huang Z, Huang Y, Wu YY, Zhang WW (2009) Finishing advanced surface of magnesium alloy tube based on abrasive belt grinding technology. Mater Sci Forum 610-613:975–978

Huang Z, Huang Y, Zhang MD, Guo XD (2008) Development of the 6-axles CNC abrasive belt grinding machine. Key Eng Mater 359(11):574–578

Huang Z, Huang Y, Zhang MD, Guo XD (2008) Testing of a six-axis computer numerical control abrasive belt grinding machine based on free-form surfaces. J Chongqing Univ 31(06):598–602

Wu JQ, Huang Y, Huang Z (2010) The analysis of four-axis belt grinding for marine propeller blade. Adv Mater Res 154-155(10):647–653

Duan JH, Shi YY, Zhang JF, Dong T, Li XB (2013) Flexible polishing technology for blade of aviation engine. Acta Aeronautica Et Astronautica Sinica 33(03):573–578

Li XB, Shi YY, Zhao PB, Duan JH (2012) Research on polishing force control technology of aero-engine blade in belt polishing. Comput Integr Manufac Syst 18(06):1209–1214

Zhao PB, Shi YY, Li XB (2013) Compensation control of belt polishing force for aero-engine blade based on disturbance observer. Comput Integr Manufac Syst 19(06):1279–1287

Ren J, Zhang HP, Wang GL (2006) Research of robotic automatic polishing system for plasma spray rapid mould. Spec Form 41(04):88–91

Han GC, Zhang HO, Wang GL (2007) Numerical simulation & experiments of robotic plasma spray forming process. J Huazhong Univ Sci Technol 35(05):62–68

Ji SM, Zhou LB, Tan DP (2013) Optimization method of technological parameters of softness abrasive flow precision machining. Chin Mech Eng 24(14):1943–1950

Xu JL (2012) High-efficiency soft abrasive flow precision machining method and its measurement and control system. Dissertation, Zhejiang University of Technology.

Tsai MJ, Chang JL, Haung JF (2005) Development of an automatic mold polishing system. IEEETrans Autom Sci Eng 2(04):393–397

Tsai MJ, Haung JF (2006) Efficient automatic polishing process with a new compliant abrasive tool. Int J Adv Manuf Technol 30(09):817–827

Tsai MJ, Haung JF, Kao WL (2009) Robotic polishing of precision molds with uniform material removal control. Int J Mach Tool Manu 49(11):886–895

Ahn JH, Shen YF, Kim HY, Jeong HD, Cho KK (2001) Development of a sensor information integrated export system for optimizing die polishing. Robot Com-Int Manuf 17(04):269–276

Ahn JH, Lee MC, Jeong HD, Kim SR, Cho KK (2002) Intelligently automated polishing for high quality surface formation of sculptured die. J Mater Process Tech 130(02):339–344

Wu XX (2003) Application of artificial neural network in resolving machining error. Dissertation, Jilin University.

Han XJ, Gou ZJ, Mu DQ, Ji QF (1998) A study on the influence of grinding wheel unbalance on the ground surface waviness. Trans Chin Soc Agric Mach 29(01):104–107

Sheng XM, Zi JL, Mi HQ, Chen T (2006) Research on surface waviness of advanced ceramics in high efficiency surface grinding. J Eng Design 13(06):421–425

Parenti P, Leonesio M, Cassinari A, Bianchi G, Monno M (2015) A model-based approach for online estimation of surface waviness in roll grinding. Int J Adv Manuf Tech 79(05):1195–1208

Wang X, Gao H, Chen Y, Guo D (2016) A water dissolution method for removing micro-waviness caused by SPDT process on KDP crystals. Int J Adv Manuf Tech 85(05):1347–1360

Zhou JM, Hognas S, Stahl JE (2010) Improving waviness of bore in precision hard turning by pressurized coolant. Int J Adv Manuf Tech 49(05):469–474

Cao Y, Guan J, Li B, Chen X, Yang J, Gan C (2013) Modeling and simulation of grinding surface topography considering wheel vibration. Int J Adv Manuf Tech 66(05):937–945

Kim JD, Lee DH, Lee KB (2005) The effects of dynamic characteristics on the surface texture in mirror grinding. Int J Adv Manuf Tech 27(03):274–280

Chen S, Cheung C, Zhao C, Zhang F (2016) Simulated and measured surface roughness in high-speed grinding of silicon carbide wafers. Int J Adv Manuf Tech: 1-12.

Yin DZ, Liu CJ, Liu BW (2014) Mechanism and countermeasures of grinding ripple in gantry. Metal Processing (Cold Working) 21:78–80

Chen DJ, Fan JW, Li HY (2013) Relationship between waviness in ultra-precision machining and spindle unbalance. J Mech Eng 49(01):191–198

Li LJ (2008) Experimental research on surface waviness and dynamic characteristics of engineering ceramics in surface grinding. Dissertation, Tianjin University.

Chui C K (1992) An introduction to wavelets. New York.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, X., Wu, D., Yang, B. et al. Research on the mechanism of milling surface waviness formation in thin-walled blades. Int J Adv Manuf Technol 93, 2459–2470 (2017). https://doi.org/10.1007/s00170-017-0669-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0669-3