Abstract

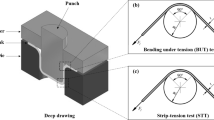

Springback, which occurs during stamping of shallow-drawn titanium alloy sheets, can negatively influence the stamping accuracy and reliability of follow-up assembly and welding of parts and restrict the application of titanium alloy sheets when high precision is a requirement. Therefore, accurate prediction and control of springback in titanium alloy sheets is an industrial problem that requires urgent attention. In this paper, a TA2M titanium alloy box formed via shallow drawing is used as the research object and springback control during stamping is attempted by varying the magnitude and mode of the blank holder force (VBHF) and height of a controllable drawbead. The influences of drawbead height, VBHF magnitude, and loading mode on the resulting sheet springback are determined by means of finite element simulation and experimentation to determine the best combination yielding the minimum springback. The results of this research provide a reliable reference for future efforts to form tough materials.

Similar content being viewed by others

References

Tan FX, Li MZ, Cai ZY, Li XJ (2009) Formability analysis on the process of multi-point forming for titanium alloy retiary sheet. Int J Adv Manuf Technol 41(11):1059–1065

Xiao R, Li XX, Lang LH, Song Q, Liu KN (2017) Forming limit in thermal cruciform biaxial tensile testing of titanium alloy. J Mater Process Technol 240:354–361

Satoh J, Gotoh M, Maeda Y (2003) Stretch-drawing of titanium sheets. J Mater Process Technol 139(1–3):201–207

Behera AK, Lu B, Ou H (2016) Characterization of shape and dimensional accuracy of incrementally formed titanium sheet parts with intermediate curvatures between two feature types. Int J Adv Manuf Technol 83(5):1099–1111

Yang HC, Chen ZT, Zhou ZT (2015) Influence of cutting speed and tool wear on the surface integrity of the titanium alloy Ti-1023 during milling. Int J Adv Manuf Technol 78(5):1113–1126

Marretta L, Lorenzo RD (2010) Influence of material properties variability on springback and thinning in sheet stamping processes: a stochastic analysis. Int J Adv Manuf Technol 51(1):117–134

Vasudevan D, Srinivasan R, Padmanabhan P (2011) Effect of process parameters on springback behaviour during air bending of electrogalvanised steel sheet. J Zhejiang Univ Sci A 12(3):183–189

Duchêne L, Guzmán CF, Behera AK, Duflou JR, Habraken AM (2013) Numerical simulation of a pyramid steel sheet formed by single point incremental forming using solid-shell finite elements. Key Eng Mater 549:180–188

Behera AK, Gu J, Lauwers B, Duflou JR (2012) Influence of material properties on accuracy response surfaces in single point incremental forming. Key Eng Mater 504-506:919–924

Essa K, Hartley P (2011) An assessment of various process strategies for improving precision in single point incremental forming. Int J Mater Form 4(4):401–412

Su CJ, Zhao J, Guan YP (2010) Quantitative analysis of cap-shape bending and springback. J Mech Eng 46(8):42–50

Duan YC, Guan YP, Zhao J (2012) Prediction and experiment verification of spring-back of tailor welded blanks air bending process. J Mech Eng 48(20):63–69

He DH, Li DS, Li XQ, Jin CH (2010) Optimization on springback reduction in cold stretch forming of titanium alloys aircraft skin. Trans Nonferrous Metals Soc China 12:2350–2357

Wei Z, Zhang ZL, Dong XH (2006) Deep drawing of rectangle parts using variable blank holder force. Int J Adv Manuf Technol 29(9):885–889

Kitayama S, Natsume S, Yamazaki K, Han J, Uchida H (2016) Numerical investigation and optimization of pulsating and variable blank holder force for identification of formability window for deep drawing of cylindrical cup. Int J Adv Manuf Technol 82(1):583–593

Mrad H, Bouazara M, Aryanpour G (2013) A reliability study of springback on the sheet metal forming process under probabilistic variation of prestrain and blank holder force. Acta Mech Sinica 29(4):557–566

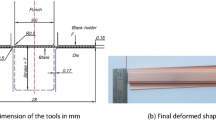

Su CJ, Wang XT, Wang Q (2015) Sheet metal springback control by variable blank holder force and controllable drawbead. J Plast Eng 22(6):47–51

Su CJ, Zhang P, Wang XT, Wang Q (2016) Influence rule of controllable draw-bead on springback in hat-shape sheet bending. J Plast Eng 23(2):81–86

Zhou J, Hua JJ, Yang DS, Zhuang YY, Yi ZH (2010) Deep drawing simulation for high-strength steel box of controllable drawbead. J Chongqing Univ 33(6):42–49

Wang GK, Cheng SY, Li SY, Zhang XW (2011) Application of numerical simulation in stamping process of complex box-type parts. Adv Mater Res 291-294:579–584

Acquisto LD, Fratini L (2006) Springback effect evaluation in three-dimensional stamping processes at the varying of blankholder force. Proc IMechE 220(11):1827–1837

Ma GY, Huang BB, Jiang SB, Chen K (2013) Analysis of process parameters influencing V-bending based on Dynaform. Appl Mech Mater 423-426:1858–1861

Zeng X, Peng BY, Liao LZ, Cheng YK (2014) Application research and analysis of bending springback of semi-circular arc stamping parts based on DYNAFORM. Appl Mech Mater 543-547:3931–3934

Koyama H, Wagoner RH, Manabe K (2004) Blank holding force control in panel stamping process using a database and FEM-assisted intelligent press control system. J Mater Process Technol 152(2):190–196

Meng DA, Zhao SD, Li L, Liu C (2016) A servo-motor driven active blank holder control system for deep drawing process. Int J Adv Manuf Technol 87(9):3185–3193

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, C., Zhang, K., Lou, S. et al. Effects of variable blank holder forces and a controllable drawbead on the springback of shallow-drawn TA2M titanium alloy boxes. Int J Adv Manuf Technol 93, 1627–1635 (2017). https://doi.org/10.1007/s00170-017-0620-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0620-7