Abstract

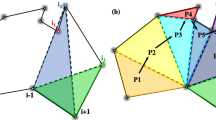

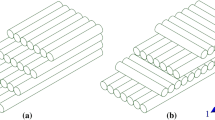

In additive manufacturing, fused deposition modeling (FDM) is widely used for its simplicity and ease of use. However, it exhibits longer printing times compared with other types of three-dimensional printers. One of the causes of the slow printing speed is infill, which is uniform structure that uses excessive material. The recently studied block-based infill generation method effectively reduced material usage and printing time with adaptive structure through the merging and splitting of unit blocks. Methods to increase the effectiveness of the block-based infill generation method have been sought in this paper. First, the directionality of the block’s surface was increased by substituting the previously used cubic unit block with octahedron and tetrahedron unit blocks to generate infill with more flexibility. Second, a quantitative splitting algorithm was proposed to solve the determination of order and direction of infill generation, which is an NP-hard problem. In most cases, the extended block-based infill generated with these two modifications showed reduced material usage and faster printing time compared with the cubic block-based infill generated.

Similar content being viewed by others

References

Lee J, Lee K (2016) Block-based inner support structure generation algorithm for 3D printing using fused deposition modeling. The International Journal of Advanced Manufacturing Technology, 1–13

Melchels FPW, Domingos MAN, Klein TJ, Malda J, Bartolo PJ, Hutmacher DW (2012) Additive manufacturing of tissues and organs. Prog Polym Sci 37(8):1079–1104

Murphy SV, Atala A (2014) 3D bioprinting of tissues and organs. Nat Biotechnol 32(8):773–785

Sun J, Zhou W, Huang D, Fuh JY, Hong GS (2015) An overview of 3D printing technologies for food fabrication. Food and bioprocess technology 8(8):1605–1615

Gao W, Zhang Y, Ramanujan D, Ramani K, Chen Y, Williams CB, Wang CCL, Shin YC, Zhang S, Zavattieri PD (2015) The status, challenges, and future of additive manufacturing in engineering. Comput Aided Des 69:65–89

Campbell I, Bourell D, Gibson I (2012) Additive manufacturing: rapid prototyping comes of age. Rapid Prototyp J 18(4):255– 258

Huang SH, Liu P, Mokasdar A, Hou L (2013) Additive manufacturing and its societal impact: a literature review. The International Journal of Advanced Manufacturing Technology

Mai J, Zhang L, Tao F, Ren L (2016) Customized production based on distributed 3D printing services in cloud manufacturing. Int J Adv Manuf Technol 84(1-4):71–83

Schmidt R, Umetani N (2014) Branching support structures for 3D printing. ACM SIGGRAPH Talks’14

Vanek J, Galicia JA, Benes B (2014) Clever support: Efficient support structure generation for digital fabrication. Comput Graphics Forum 33(5):117–125

Vanek J, Galicia JA, Benes B, Měch R, Carr N, Stava O, Miller GS (2014) PackMerger: A 3D print volume optimizer. Comput Graphics Forum 33(6):322–332

Luo L, Baran I, Rusinkiewicz S, Matusik W (2012) Chopper: partitioning models into 3D-printable parts. ACM Trans Graph 31(6):129

Wei XR, Zhang YH, Geng GH (2016) No-infill 3D Printing. 3D Research 7(3):24

Wang W, Wang TY, Yang Z, Liu L, Tong X, Tong W, Deng J, Chen F, Liu X (2013) Cost-effective printing of 3D objects with skinframe structures. ACM Trans Graph 32(6):177

Zhang X, Xia Y, Wang J, Yang Z, Tu C, Wang W (2015) Medial axis tree-an internal supporting structure for 3D printing. Comput Aided Geom Des 35:149–162

Lu L, Shaft A, Zhao H, Wei Y, Fan QN, Chen X, Savoye Y, Tu CH, Daniel CO, Chen BQ (2014) Build-to-last: strength to weight 3D printed objects. ACM Trans Graph 33(4):97

Li D, Dai N, Jiang X, Chen X (2016) Interior structural optimization based on the density-variable shape modeling of 3D printed objects. Int J Adv Manuf Technol 83(9-12):1627–1635

Strano G, Hao L, Everson RM, Evans KE (2013) A new approach to the design and optimisation of support structures in additive manufacturing. Int J Adv Manuf Technol 66(9-12):1247–1254

Prévost R, Whiting E, Lefebvre S, Sorkine-Hornung O (2013) Make it stand: balancing shapes for 3D fabrication. ACM Trans Graph (TOG) 32(4):81

Christiansen AN, Schmidt R, Bærentzen JA (2015) Automatic balancing of 3D models. Comput Aided Des 58:236–241

Wu J, Wang CC, Zhang X, Westermann R (2016) Self-supporting rhombic infill structures for additive manufacturing. Comput Aided Des 80:32–42

Xie Y, Chen X (2017) Support-free interior carving for 3D printing. Visual Informatics

Graham RL, Hell P (1985) On the history of the minimum spanning tree problem. IEEE Ann Hist Comput 7(1):43–57

3DWOX DP200 (2016) FDM 3D Printer. http://3dprinter.sindoh.com/

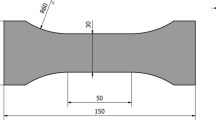

(2015) ASTM D695-15 Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International, West Conshohocken, PA. doi:10.1520/D0695-15

Wu J, Aage N, Westermann r, Sigmund O (2017) Infill Optimization for Additive Manufacturing–Approaching Bone-like Porous Structures. IEEE Transactions on Visualization and Computer Graphics

Stava O, Vanek J, Benes B, Carr N, MěchR (2012) Stress relief: improving structural strength of 3D printable objects. ACM Trans Graph (TOG) 31(4):48

Acknowledgments

The Institute of Engineering Research at Seoul National University provided research facilities for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, T., Lee, J. & Lee, K. Extended block based infill generation. Int J Adv Manuf Technol 93, 1415–1430 (2017). https://doi.org/10.1007/s00170-017-0572-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0572-y