Abstract

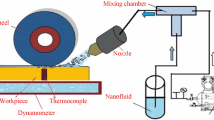

Application of vegetable-based nanolubricants in machining operations has been promoted due to the environmental concerns and higher demand for better quality of machined parts. In this study, lubrication properties of copper oxide nanofluids in surface grinding of AISI 1045 hardened steel are investigated. These nanofluids were synthesized by submerged electro discharge process, exposed to ultrasonic agitation in the presence of Tween 20 as dispersant and sprayed in grinding position using minimum quantity lubrication system. The base fluid is an emulsion of canola oil and distilled water with vegetable oil acting as triglyceride agent. Convective heat transfer coefficients of different lubrication systems in grinding are measured using an innovative approach to better explore the cooling mechanisms involved in grinding process with or without the application of nanolubricants. The variation of grinding forces and sub-surface temperature of workpiece are recorded at different lubrication conditions. These parameters along with surface roughness, micro-hardness, and microscopic observations of ground surfaces are employed to evaluate the performance of synthesized nanofluids as lubricants in grinding. The results show that the synthesized nanofluids are effective in reducing the grinding forces and temperatures especially in extreme machining conditions. Better surface integrity of ground parts is observed in all grinding conditions through the application of CuO nanofluids as lubricant in minimum quantity lubrication system.

Similar content being viewed by others

References

Fritz Klocke EH, Kuchie A (2009) Principles of cutting edge engagement. In: Klocke F, Manufacturing processes 2. Springer, Berlin Heidelberg

Shen B, Shih AJ, Xiao G (2011) A heat transfer model based on finite difference method for grinding. J Manuf Sci Eng 133:1–10

Kalita P, Malshe AP, Jiang W, Shih AJ (2010) Tribological study of nano lubricant integrated soybean oil for minimum quantity lubrication (MQL) grinding. Transactions of NAMRI/SME 38:137–144

Srikant RR, Prasad MMS, Amrita M, Sitaramaraju AV, Krishna PV (2014) Nanofluids as a potential solution for minimum quantity lubrication: a review. Institution of Mechanical Engineering, Proc IMechE Part B: Journal of Engineering Manufacture, 228: 3–20

Lee PH, Nam JS, Li C, Lee SW (2012) An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). International Journal of Precision Engineering and Manufacture 13:331–338

Ju C, Keranen LP, Haapala KR, Michalek DJ, Sutherland JW (2005) Issues associated with MQL implementation: effect on peripheral milling process performance and impact on machining economics. ASME Proceedings, Manufacturing, IMECE 79259, pp. 3–12

Dhar NR, Ahmed MT, Islam S (2007) An experimental investigation on effect of minimum quantity lubrication in machining AISI 1040 steel. Int J Mach Tools Manuf 47:748–753

Sadeghi MH, Haddad MJ, Tawakoli T, Emami M (2009) Minimal quantity lubrication-MQL in grinding of Ti–6Al–4V titanium alloy. Int J Adv Manuf Technol 44:487–500

Barczak LM, Batako ADL, Morgan MN (2010) A study of plane surface grinding under minimum quantity lubrication (MQL) conditions. Int J Mach Tools Manuf 50:977–985

Verma A, Malshe AP, Brown W, Jiang W, Adhvaryu A, McCluskey P (2006) Exploring mechanical synthesis of inorganic nanoparticles of MoS2 lubricant and its composite with organic medium for advanced manufacturing. 4th International Symposium on Nanomanufacturing (ISNM)

Xu T, Zhang J, Xu K (1996) The ball-bearing effect of diamond nanoparticles as an oil additive. Appl Phys 29:2932–2937

Stachowiak GW, Batchelor AW (2005) Engineering tribology, 3rd edn. Elsevier, Oxford

Krishna PV, Srikantb RR, Rao DN (2010) Experimental investigation on the performance of nanoboric acid suspensions in SAE-40 and coconut oil during turning of AISI 1040 steel. Int J Mach Tools Manuf 50:911–916

Shen B, Shin AJ, Tung SC (2008) Application of nanofluids in minimum quantity lubrication grinding, Society of Tribologists and Lubrication Engineers. Tribol Trans 51:730–737

Shen B, Malshe AP, Kalita P, Shih AJ (2008) Performance of novel MoS2 nanoparticles based grinding fluids in minimum quantity lubrication grinding. Transactions of NAMRI/SME 36:358–364

Nguyen TK, Do I, Kwon P (2012) A tribological study of vegetable oil enhanced by nano-platelets and implication in MQL machining. Int J Precis Eng Manuf 13:1077–1083

Setti D, Sinha MK, Ghosh S, Rao PV (2014) An investigation into the application of Al2O3 nanofluid-based minimum quantity lubrication technique for grinding of Ti-6Al-4V. International Journal of Precision Technology 4:268–279

Hadi M, Atefi R (2015) Effect of minimum quantity lubrication with gamma-Al2O3 nanoparticles on surface roughness in milling AISI D3 steel. Indian Journal of Science and Technology 8:296–300

Dongkun Z, Changhe L, Dongzhou J, Yanbin Z, Xiaowei Z (2015) Specific grinding energy and surface roughness of nanoparticle jet minimum quantity lubrication in grinding. Chinese Society of Aeronautics and Astronautics and Beihang University, Chinese Journal of Aeronautics, 28: 570–581

Jia D, Li C, Zhang D, Zhang Y, Zhang X (2014) Experimental verification of nanoparticle jet minimum quantity lubrication effectiveness in grinding. J Nanopart Res 16:1–15

Prabhu S, Vinayagam BK (2010) Nano surface generation of grinding process using carbon nano tubes. Sãdhanã, Indian Academy of Sciences 35:747–760

Sayuti M, Sarhan AAD, Tanaka T, Hamdi M, Saito Y (2013) Cutting force reduction and surface quality improvement in machining of aerospace duralumin AL-2017-T4 using carbon onion nanolubrication system. Int J Adv Manuf Technol 65:1493–1500

Alberts M, Kalaitzidou K, Melkote S (2009) An investigation of graphite nanoplatelets as lubricant in grinding. Int J Mach Tools Manuf 49:966–970

Su Y, Gong L, Chen D (2015) An investigation on tribological properties and lubrication mechanism of graphite nanoparticles as vegetable based oil additive. Hindawi Publishing Corporation, Journal of Nanomaterials, 2015: 1–7

Shabgard M, Seyedzavvar M, Abbasi H (2016) Investigation into features of graphite nanofluid synthesized using electro discharge process. Int J Adv Manuf Technol:1–14. doi:10.1007/s00170-016-9388-4

Çengel YA, Ghajar AJ (2015) Heat and mass transfer, fundaments and application. McGraw-Hill Education, New York

AISI 1045 medium carbon steel, AZO Materials, http://www.azom.com/article.aspx?ArticleID=6130

1045 medium tensile carbon steel, Interlloy Pty Ltd, http://www.interlloy.com.au/our-products/carbon-steels/1045-medium-tensile-carbon-steel-bar/

Datasheet: L6D8 load cell, Zemic Europe BV, http://loadcell.ir/document/Zemic/L6D8/Datasheet%20L6D8.pdf

Minimal quantity lubrication (MQL) for dry machining processes, http://www.skf.com/binary/79-32233/1-5102-EN.pdf, page 5.

Kenbeck D, Bunemann TF (2009) Organic friction modifiers. In: Rudnick LR (ed) Lubricant additives chemistry and applications. CRC Press Taylor & Francis Group, Florida

Rudnick LR (2009) Additives for industrial lubricant applications. In: Lubricant additives chemistry and applications. CRC Press Taylor & Francis Group, Florida

Suarez AN, Grahn M, Pasaribu R, Larsson R (2010) The influence of base oil polarity on the tribological performance of zinc dialkyl dithiophosphate additives. Tribol Int 43:2268–2278

Hsu SM, Gates RS (2005) Boundary lubricating films: formation and lubrication mechanism. Tribol Int 38:305–312

Chang H, Lan CW, Chen CH, Kao MJ, Guo JB (2014) Anti-wear and friction properties of nanoparticles as additives in the lithium grease. Int J Precis Eng Manuf 15:2059–2063

Lovell MR, Kabir MA, Menezes PL, Higgs CF III (2010) Influence of boric acid additive size on green lubricant performance. Philosophical Transactions of Royal Society A 368:4851–4868

Thottackkad MV, Perikinalil RK, Kumarapillai PN (2012) Experimental evaluation on the tribological properties of coconut oil by the addition of CuO nanoparticles. Int J Precis Eng Manuf 13:111–116

Elyasi P, Shateri AR (2016) MHD boundary layer flow and heat transfer of Newtonian nanofluids over a stretching sheet with variable velocity and temperature distribution. Transport Phenomena in Nano and Micro Scales 4:28–40

Kwak K, Kim C (2005) Viscosity and thermal conductivity of copper oxide nanofluid dispersed in ethylene glycol. Korea-Australia Rheology Journal 17:35–40

Pashmforoush F, Rahimi A (2015) Nano-finishing of BK7 optical glass using magnetic abrasive finishing process. Appl Opt 54:2199–2207

Kiyak M, Cakir O, Altan E (2006) A study on surface roughness in external cylindrical grinding. 12th International Scientific Conference on Achievements in Mechanical and Materials Engineering, Polish Academy of Sciences, Gliwice-Zakopane, Poland, 459–462

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shabgard, M., Seyedzavvar, M. & Mohammadpourfard, M. Experimental investigation into lubrication properties and mechanism of vegetable-based CuO nanofluid in MQL grinding. Int J Adv Manuf Technol 92, 3807–3823 (2017). https://doi.org/10.1007/s00170-017-0319-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0319-9