Abstract

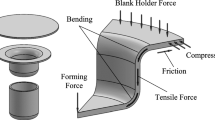

To manufacture a component with uniform deformation as well as homogeneous properties to fulfill the need of good consistency in service, both tool geometry and forming method were taken into account on the forming of double curvature shell. Experimental setups with planed and curved blank-holder surfaces combined with hydroforming process were performed on the evaluation of stain and thickness distribution compared with conventional deep drawing process. The average strain and its standard deviation on the formed shell were calculated as the indicators of whole strain level and strain uniformity. The results show that the most homogeneous strain, tensile strength, and micro-hardness can be achieved by the combination of hydroforming process and curved blank-holder surface.

Similar content being viewed by others

References

Li Y, Wang Z (2009) Finite element analysis of stiffness and static dent resistance of aluminum alloy double-curved panel in viscous pressure forming. Trans. Nonferrous Met. Soc. China 19:s321–s317

Borah U, Venugopal S, Nagarajan R, Sivaprasad PV, Venugopal S, Baldev R (2008) Estimation of springback in double-curvature forming of plates: experimental evaluation and process modeling. Int J Mech Sci 50:704–718

Zhang J, Deng Y, Li S, Chen Z, Zhang X (2013a) Creep age forming of 2124 aluminum alloy with single/double curvature. Trans Nonferrous Met SocChina 23:1922–1929

Zhang Q, Cai Z, Zhang Y, Li M (2013b) Springback compensation method for doubly curved plate in multi-point forming. Mater Des 47:377–385

Donnell MO, Leacock AG, Banabic D, Brown D, McMurray RJ (2008) The effect of pre-strain and solution heat treatment on the formability of a 2024 Aluminium alloy. Int J Mater Form 1(Suppl 1):257–260

Dehua H, Xiaoqiang L, Dongsheng L, Weijun Y (2010) Process design for multi-stage stretch forming of aluminum alloy aircraft skin. Trans. Nonferrous Met. Soc. China 20:1053–1058

Zhan L, Lin J, Dean TA (2011) A review of the development of creep age forming: experimentation, modelling and applications. International Journal of Machine Tools & Manufacture 51:1–17

Liu X, Xu Y, Yuan S (2011) Hydro-forming of aluminum alloy complex-shaped components. Trans Nonferrous Met Soc China 21:s417–ss42

Lihui L, Tao L, Dongyang A, Cailou C, Karl Brian M. N, Joachim D (2009) Investigation into hydromechanical deep drawing of aluminum alloy—complicated components in aircraft manufacturing. Mater Sci Eng A 499:320–324

Yongming Wang, Lihui Lang, Pengzhi Cheng, Yasu Xie (2011) Numerical Investigation into the springback of double curved shallow shells after uniform hydroforming. Proceedings of the 5th International Conference on Tube Hydroforming. July 24–27, Noboribetsu (Hokkaido), Japan

Tolazzi M (2010) Hydroforming applications in automotive: a review. Int J Mater Form 3(Suppl.1):307–310

Zhang S, Lang L, Dangchang K, Danckert J, Nielsen KB (2000) Hydromechanical deep-drawing of aluminum parabolic workpieces—experiments and numerical simulation. International Journal of Machine Tools & Manufacture 40:1479–1492

Chen B, Xu Y, Yuan S (2013) Investigation into influence of pre-bulging on subsequent hydrodynamic deep drawing. Rev Adv Mater Sci 33(5):423

Yongchao Xu, Wei Liu, Shijian Yuan (2012) Effects of counter pre-bulging on sheet hydroforming.7th International Conference on Hydroforming of Sheets, Tube and Profiles, May,21–22, Stuttgart, Fellbach/Stuttgart, Germany: 139–151

Yizhe C, Wei L, Shijian Y (2015) Strength and formability improvement of al-cu-Mn aluminum alloy complex parts by thermomechanical treatment with sheet hydroforming. JOM 67(5):938–947

Stefan Schwarz, Michael Rupp, Hendrik Rothe, Konrad Schnupp, Christian Siebenwurst (2005) Production of a High-strength steel roof outer panel by AHU hydromechanical sheet forming. The 4th International Conference on Hydroforming of Tubes, Extrusions and Sheet Metals. Germany, 37–58

ASTM Standards (2002) ASTM B557–02. USA

Thiruvarudchelvan S, Tan MJ (2006) A note on fluid-pressure-assisted deep drawing processes. J Mater Process Tech 172:174–181

Zhang SH, Danckert J (1998) Development of hydro-mechanical deep drawing. J Mater Process Technol 83(1):14–25

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

(a) Both tool geometry and forming method were considered on uniformity of strain and property.

(b) Hydroforming process has great effect both on whole strain level and strain uniformity with planed and curved blank-holder.

(c) Both the whole strain level and the strain uniformity can be improved by hydroforming process with curved blank-holder.

Rights and permissions

About this article

Cite this article

Liu, W., An, L. & Yuan, S. Enhancement on deformation uniformity of double curvature shell by hydroforming process and curved blank-holder surface. Int J Adv Manuf Technol 92, 1913–1922 (2017). https://doi.org/10.1007/s00170-017-0301-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0301-6