Abstract

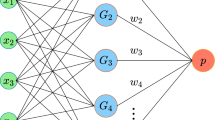

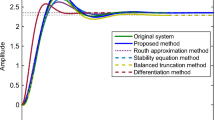

Based on third-order Newton interpolation polynomial and direct integration scheme (DIS), this paper proposes a method to generate stability lobe diagram in milling process. The dynamic model of milling process with consideration of regeneration effect is described by time periodic delay-differential equation (DDE). Then, the DDE is rewritten as state space equation by a transformation. After equally discretizing the time delay into a series of small time intervals, the state space equation of milling system is integrated on the small time interval. Both the state term and delayed term are interpolated by third-order Newton interpolation polynomial, and the periodic-coefficient matrix is interpolated by first-order Newton interpolation polynomial. The state transition matrix which reflects the discrete mapping relation of dynamic responses for current tooth pass period and immediate previous tooth pass period is obtained directly. The accuracy of the proposed method is evaluated by comparing with benchmark methods in terms of the rate of convergence. The efficiency of the proposed method is verified through the comparison of computational time with existing methods. The proposed method is proved to be an accurate and efficient method by the comparison results. The distinction between up-milling and down-milling operations is also analyzed by comparing the stability lobe diagrams for these two operations. Besides, according to the analysis of rate of convergence, the number of substitutions, which are used to convert the variables located out of the required range into the required range, may affect the results of stability lobe diagrams. Moreover, the stability lobe diagram cannot be generated by using fourth-order updated full-discretization method.

Similar content being viewed by others

References

Budak E (2006) Analytical models for high performance milling. Part II: Process dynamics and stability. Int J Mach Tools Manuf 46(12):1489–1499

Altintas Y (2000) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design. Cambridge University Press, Cambridge

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann-Manuf Techn 53(2):619–642. doi:10.1016/S0007-8506(07)60032-8

Quintana G, Ciurana J (2011) Chatter in machining process: a review. Int J Mach Tools Manuf 51(5):363–376. doi:10.1016/j.ijmachtools.2011.01.001

Tlusty J, Polacek A, Danek C, Spacek J (1962) Selbsterregte Schwingungen an Werkzeugmaschinen. VEB Verlag Technik, Berlin

Tobias SA (1965) Machine tool vibration. Blackie, London

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann-Manuf Techn 44(1):357–362. doi:10.1016/S0007-8506(07)62342-7

Merdol SD, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng 126(3):459–466. doi:10.1115/1.1765139

Shorr MJ, Liang SY (1996) Chatter stability analysis for end milling via convolution modeling. Int J Adv Manuf Technol 11(5):311–318. doi:10.1007/BF01845689

Li HZ, Li XP, Chen Q (2003) A novel chatter stability criterion for the modeling and simulation of the dynamic milling process in the time domain. Int J Adv Manuf Technol 22:619–625. doi:10.1007/s00170-003-1562-9

Balachandran B (2001) Nonlinear dynamics of milling processes. PHILOS T R SOC A 359(1781):793–819. doi:10.1098/rsta.2000.0755

Balachandran B, Zhao MX (2000) A mechanics based model for study of dynamics of milling operations. Meccanica 35(2):89–109. doi:10.1023/A:1004887301926

Zhao MX, Balachandran B (2001) Dynamics and stability of milling process. Int J Solids Struct 38(10):2233–2248. doi:10.1016/S0020-7683(00)00164-5

Balachandran B, Gilsinn D (2005) Non-linear oscillations of milling. Math Comp Model Dyn 11(3):273–290. doi:10.1080/13873950500076479

Bayly PV, Halley JE, Mann BP, Davies MA (2003) Stability of interrupted cutting by temporal finite element analysis. J Manuf Sci Eng 125(2):220–225. doi:10.1115/1.1556860

Butcher EA, Bobrenkov OA, Bueler E, Nindujarla P (2009) Analysis of milling stability by the Chebyshev collocation method: algorithm and optimal stable immersion levels. J Comput Nonlinear Dynam 4(3):031003. doi:10.1115/1.3124088

Insperger T, Stépán G (2004) Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Meth Eng 61(1):117–141. doi:10.1002/nme.1061

Insperger T, Stépán G, Turi J (2008) On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib 313(1–2):334–341. doi:10.1016/j.jsv.2007.11.040

Jin G, Qi HJ, Cai YJ, Zhang QC (2016) Stability prediction for milling process with multiple delays using an improved semi-discretization method. Mathematical Methods in the Applied Sciences 39(4):949–958. doi:10.1002/mma.3543

Li M, Zhang G, Huang Y (2013) Complete discretization scheme for milling stability prediction. Nonlinear Dynam 71:187–199. doi:10.1007/s11071-012-0651-4

Xie QZ (2016) Milling stability prediction using an improved complete discretization method. Int J Adv Manuf Technol 83(5–8):815–821. doi:10.1007/s00170-015-7626-9

Li Z, Yang Z, Peng Y, Zhu F, Ming X (2015) Prediction of chatter stability for milling process using Runge-Kutta-based complete discretization method. Int J Adv Manuf Technol 86(1):943–952. doi:10.1007/s00170-015-8207-7

Ozoegwu CG (2016) High order vector numerical integration schemes applied in state space milling stability analysis. Appl Math Comput 273:1025–1040. doi:10.1016/j.amc.2015.10.069

Ding Y, Zhu LM, Zhang XJ, Ding H (2010a) A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509. doi:10.1016/j.ijmachtools.2010.01.003

Ding Y, Zhu LM, Zhang XJ, Ding H (2010b) Second-order full-discretization method for milling stability prediction. Int J Mach Tools Manuf 50(10):926–932. doi:10.1016/j.ijmachtools. 2010.05.005

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Numerical integration method for prediction of milling stability. J Manuf Sci Eng 133(3):031005. doi:10.1115/1.4004136

Liang XG, Yao ZQ, Luo L, Hu J (2013) An improved numerical integration method for predicting milling stability with varying time delay. Int J Adv Manuf Technol 68:1967–1976. doi:10.1007/s00170-013-4813-4

Guo Q, Sun YW, Jiang Y (2012) On the accurate calculation of milling stability limits using third-order full-discretization method. Int J Mach Tools Manuf 62:61–66. doi:10.1016/j.ijmachtools.2012.05.001

Guo Q, Jiang Y, Zhao B, Ming P (2016) Chatter modeling and stability lobes predicting for non-uniform helix tools. Int J Adv Manuf Technol (on line). doi:10.1007/s00170-016-8458-y

Ozoegwu CG (2014) Least squares approximated stability boundaries of milling process. Int J Mach Tools Manuf 79:24–30. doi:10.1016/j.ijmachtools.2014.02.001

Ozoegwu CG, Omenyi SN, Ofochebe SM (2015) Hyper-third order full-discretization methods in milling stability prediction. Int J Mach Tools Manuf 92:1–9. doi:10.1016/j.ijmachtools.2015.02.007

Tang X, Peng F, Yan R, Gong Y, Li Y, Jiang L (2016) Accurate and efficient prediction of milling stability with updated full-discretization method. Int J Adv Manuf Technol (on line). doi:10.1007/s00170-016-8923-7

Long X, Balachandran B (2010) Stability of up-milling and down-milling operations with variable spindle speed. J Vib Control 16(7–8):1151–1168. doi:10.1177/1077546309341131

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, Z., Wang, X., Liu, Z. et al. Third-order updated full-discretization method for milling stability prediction. Int J Adv Manuf Technol 92, 2299–2309 (2017). https://doi.org/10.1007/s00170-017-0243-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0243-z