Abstract

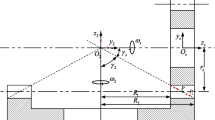

To reduce tooth surface errors and improve the quality of tooth surface morphology for the spiroid face gear manufactured roughly by die-casting, a method of shaving processing for this type of gears was developed. According to the differential geometry and the meshing theory of spatial crossed axes gears, the kinematics of the shaving processing for the spiroid face gear was analyzed, while the cutting velocity of both contact tooth surfaces was derived to illustrate the feasibility of gear shaving. With the designed tooth geometry of the shaving cutter, the simulation of generation of tooth surfaces for the spiroid face gear was developed. Machining experiments for such type gears were performed on a five-axis computer numerical control machine tool (CNC machine) with the axially grooved shaving cutters. The geometric error measurement of the shaved spiroid face gears was determined by D40 CNC gear measuring center. The research results are of sound great significance to improve the engagement and lubrication for the spiroid face gears.

Similar content being viewed by others

References

Abadjiev VI (2002) Mathematical modelling for synthesis of spatial gears. ARCHIVE Proc Inst Mech Eng E J Process Mech Eng 1989–1996 216(216):31–46

Abadjiev V, Petrova D (2003) On the synthesis and computer design of spiroid gears: a review of the Bulgarian approach. J T AM 33:3–30

Abadjiev V (2008) Bulgarian experience to design and manufacture of high reduction gears of type spiroid. Machine Design: on the occasion of 48th Anniversary of the Faculty of Technical Sciences: 75–82

Dudley DW, Radzevich SP (2012) Dudleyʼs handbook of practical gear design and manufacture. CRC Press, Boca Raton, pp 61–63

Staniek R (2006) Positioning accuracy investigations in face spiroid gears[C]. ASME ESDA 2006. Torino, Italy: 781–786

Staniek R (2011) Shaping of face toothing in flat spiroid gears. STROJ VESTN-J MECH E 57(1):47–54

Litvin FL, Donno MD (1998) Computerized design and generation of modified spiroid worm-gear drive with low transmission errors and stabilized bearing contact. Comput Methods Appl Mech Engrg 162(1):187–201

Litvin FL, Fuentes A, Zanzi C, Pontiggia M (2002) Design, generation, and stress analysis of two versions of geometry of face-gear drives. Mech Mach Theory 37(10):1179–1211

Dudas I, Bodzas S (2013) Production geometry analysis, modeling, and rapid prototyping production of manufacturing tool of spiroid face gear. Int J Adv Manuf Technol 66(66):271–281

Dudas I, Bodzas S, Dudas IS, Mandy Z (2015) Development of spiroid worm gear drive having arched profile in axial section and a new technology of spiroid worm manufacturing with lathe center displacement. Int J Adv Manuf Technol 79(9–12):1881–1892

Bodzas S, Dudas I (2016) Mathematical description and modeling of a tooth surface of spiroid face gear having arched profile in axial section. Int J Adv Manuf Technol 84(5–8):1431–1442

Yang XY, Tang JY (2014) Research on manufacturing method of CNC plunge milling for spur face-gear. J Mater Process Tech 214(12):3013–3019

Tang JY, Yang XY (2016) Research on manufacturing method of planing for spur face-gear with 4-axis CNC planer. Int J Adv Manuf Technol 82(5–8):847–858

Wang YZ, Lan Z, Hou LW, Zhao HP, Zhong Z (2015) A generating milling method for a spur face gear using a five-axis computer numerical control milling machine. Proc IMech Part B: J Eng Manuf 230(8)

Wu XT (2009) Principle of gearing, 2nd edn. Xi’an Jiaotong University Press, Xi’an, pp 160–172

Litvin FL, Fuentes A (2004) Gear geometry and applied theory. Cambridge University Press 782–788

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, Y., Liu, X., Li, Z. et al. Research on shaving processing of spiroid face gear. Int J Adv Manuf Technol 92, 605–613 (2017). https://doi.org/10.1007/s00170-017-0173-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0173-9