Abstract

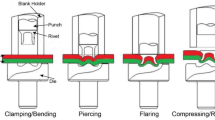

Self-piercing riveting (SPR) is a cold mechanical joining process used to join two or more sheets of materials by driving a rivet piercing through the top sheet or the top and middle sheets and subsequently lock into the bottom sheet under the guidance of a suitable die. SPR is currently the main joining method for aluminium and mixed-material lightweight automotive structures. SPR was originated half century ago, but it only had significant progress in the last 25 years due to the requirement of joining lightweight materials, such as aluminium alloy structures, aluminium-steel structures and other mixed-material structures, from the automotive industry. Compared with other conventional joining methods, SPR has many advantages including no pre-drilled holes required, no fume, no spark and low noise, no surface treatment required, ability to join multi-layer materials and mixed materials and ability to produce joints with high static and fatigue strengths. In this paper, research investigations that have been conducted on self-piercing riveting will be extensively reviewed. The current state and development of SPR process is reviewed and the influence of the key process parameters on joint quality is discussed. The mechanical properties of SPR joints, the corrosion behaviour of SPR joints, the distortion of SPR joints and the simulation of SPR process and joint performance are reviewed. Developing reliable simulation methods for SPR process and joint performance to reduce the need of physical testing has been identified as one of the main challenges.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Hulbert, J.P. (1972), Riveting without prepunching, in. Machine design

Anon (1975) Self-piercing rivets attach can handle. Engineering Materials Design 19(12):46

Gausden, D. and I. Gunn (1976), Self piercing rivets give strong sealed joints, in Design Engineering. p. 55–57

Sunday, S.P. (1983) Self-piercing rivets for aluminum components, in SAE World Congress, Paper No. 830526

Patrick, E.P. and M.L. Sharp (1992), Joining aluminum auto body structure, in SAE World Congress, Paper No. 920282

Edwards K (1992) Pierce-&-roll riveting—the alternative to spot-welding. Aluminium Industry 11(5):24–26

Doo, R. (1993) Automotive body construction using self-piercing riveting. Automotive Manufacturing International

Hill, H. (1994), Introduction to the self-pierce riveting process and equipment, in IBEC'94 - Body Assembly & Manufacturing. p. 1–9

Bokhari N (1995) Self-piercing riveting—process and equipment. Weld Met Fabrication 63(5):186–188

Moss, S. and M. Mahendran (2002), Structural behaviour of self-piercing riveted connections in steel framed housing, in 16th International Specialty Conference on Cold-Formed Steel Structures: Orlando, Florida, USA. p. 748–761

Moss SR, Mahendran M (2003) Structural behaviour of self-piercing riveted connections in G300 and G550 thin sheet steels. Advances in Structures Vols 1 and 2:275–280

Litherland, H. (1998), Self-piercing riveting for aluminium applications in Proceedings of the Seventh International Conference INALCO’98: Cambridge. p. 135–147

EAA (2011) Design with aluminium, in The aluminium automotive manual, European Aluminium Association

Abe Y, Kato T, Mori K (2006) Joinability of aluminium alloy and mild steel sheets by self piercing rivet. J Mater Process Technol 177(1–3):417–421

Miller WS et al (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng A 280(1):37–49

Audi. Self-study Programme 383 "Audi TT Coupé ‘07-Body" 2013. [cited November]; Available from: http://www.volkspage.net/technik/ssp/ssp/SSP_383.pdf

Mortimer J (2001) Jaguar uses X350 car to pioneer use of self-piercing rivets. Industrial Robot: An International Journal 28(3):192–198

Mortimer J (2005) Jaguar "roadmap" rethinks self-piercing technology. Industrial Robot: An International Journal 32(3):209–213

Mortimer, J. (2015), Atlas Copco swallows Henrob of SPR fame, in Auto Industry Newsletter

Szondy, D. (2015), Aluminum gives 2016 Jaguar XF a light touch, in New Atlas

Bonde, N. and S. Grange-Jansson (2013), Self-piercing riveting in high-strength steel—a way to increase fatigue life, in Advanced technologies & processes, IBEC '96. 1996. p. 16–20

Henrob. Automotive. (2013) [cited November]; Available from: http://www.henrob.com/GB/automotive.php.

Weber, A. (2015), Assembling Ford’s aluminum wonder truck, in Assembly

Coldwell, D. and P. Briskham (2015), Assembly of the 2015 Ford F150 using Henrob self-piercing rivet technology. 2015: Automotive Circle International Insight Edition @Ford USA

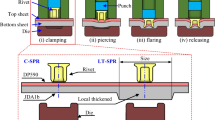

Liu Y et al (2013) Single-sided piercing riveting for adhesive bonding in vehicle body assembly. J Manuf Syst 32(3):498–504

He X, Gu F, Ball A (2012) Recent development in finite element analysis of self-piercing riveted joints. Int J Adv Manuf Technol 58(5–8):643–649

He X, Pearson I, Young K (2008) Self-pierce riveting for sheet materials: state of the art. J Mater Process Technol 199(1–3):27–36

Sui B et al (2006) A review on the development of self-piercing riveting technology for lightweight vehicle body. Automot Eng 28(1):85–89

Cacko R (2008) Review of different material separation criteria in numerical modeling of the self-piercing riveting process—SPR. Archives of Civil and Mechanical Engineering 8(2):21–30

Chrysanthou A, Sun X (2013) Self-piercing riveting : properties, processing and applications ed. Woodhead Publishing, Cambridge, Cambridge

Kaščák Ľ, Spišák E (2012) Joining materials by self-piercing riveting method. Transfer inovácií 22:43–46

Mucha J (2014) The numerical analysis of the effect of the joining process parameters on self-piercing riveting using the solid rivet. Archives of Civil and Mechanical Engineering 14(3):444–454

Mucha J (2015) The failure mechanics analysis of the solid self-piercing riveting joints. Eng Fail Anal 47(PA):77–88

Clinch Rivet Tool. (2015) [cited 2015 10/11/2015]; Available from: http://www.tox-us.com/us/products/joining-systems/tox-clinch-procedure/tox-clinchrivet.html

Mucha, J., L.u. Kaščák, and E. Spišák 2013, The experimental analysis of forming and strength of clinch riveting sheet metal joint made of different materials. Advances in Mechanical Engineering. 5

Mucha J, Witkowski W (2013) The experimental analysis of the double joint type change effect on the joint destruction process in uniaxial shearing test. Thin-Walled Struct 66:39–49

Wang B, Hao CY, Zhang JS (2006) A new self-piercing riveting process and strength evaluation. Journal of Manufacturing Science and Engineering-Transactions of the ASME 128(2):580–587

Duan H et al (2014) Rotation friction pressing riveting of AZ31 magnesium alloy sheet. Mater Des 54:414–424

Han, G., et al. (2013), A new joining process for magnesium alloys: rotation friction drilling riveting. Journal of Manufacturing Science and Engineering, Transactions of the ASME. 135(3)

Ma, Y., et al. (2015), Effect of rivet hardness and geometrical features on friction self-piercing riveted joint quality. Journal of Manufacturing Science and Engineering, Transactions of the ASME. 137(5)

Liu X et al (2016) Effects of process parameters on friction self-piercing riveting of dissimilar materials. J Mater Process Technol 237:19–30

Huang, Z., et al. (2014) Self-piercing riveting with inner flange pipe rivet. in Procedia Engineering.

Lou M et al (2014) Influence of resistance heating on self-piercing riveted dissimilar joints of AA6061-T6 and galvanized DP590. J Mater Process Technol 214(10):2119–2126

Lou, M., et al. (2013), Behavior and quality evaluation of electroplastic self-piercing riveting of aluminum alloy and advanced high strength steel. Journal of Manufacturing Science and Engineering, Transactions of the ASME, 135(1)

Westgate, S.A., et al. (2001), The development of lightweight self-piercing riveting equipment, in SAE World Congress, Paper No. 2001–01-0979

Hou, W., et al. (2004) , Characterization for quality monitoring of a self-piercing riveting, in Sheet Metal Welding conference XI: Sterling Heights, Michigan. p. Paper No. 8–3

Budde L, Lappe W, Liebrecht F (1992) Further developments in the self-piercing rivet technology. Bleche Rohre Profile 39:310–314

Lappe, W. and L. Budde (1993), Possibilities for monitoring and controlling the mechanical process in sheet metal assembly, Paderborn University

King, R.P., et al. (1995) Setting load requirements and fastening strength in the self-pierce riveting process, in Proceedings of the 11th National Conference on Manufacturing Research: Leicester, UK. p. 57–61

Atzeni E, Ippolito R, Settineri L (2009) Experimental and numerical appraisal of self-piercing riveting. CIRP Ann Manuf Technol 58(1):17–20

Haque R, Beynon JH, Durandet Y (2012) Characterisation of force-displacement curve in self-pierce riveting. Sci Technol Weld Join 17(6):476–488

Xu Y (2006) Effects of factors on physical attributes of self-piercing riveted joints. Sci Technol Weld Join 11(6):666–671

Hoang NH et al (2010) Self-piercing riveting connections using aluminium rivets. Int J Solids Struct 47(3–4):427–439

Hoang NH et al (2013) Failure of aluminium self-piercing rivets: an experimental and numerical study. Mater Des 49(0):323–335

Hoang NH et al (2011) The effect of the riveting process and aging on the mechanical behaviour of an aluminium self-piercing riveted connection. European Journal of Mechanics - A/Solids 30(5):619–630

EAA, Mechanical joining, in The aluminium automotive manual. (2002), European Aluminium Association

Henrob (2013) . Rivet types. [cited 2013 November]; Available from: http://www.henrob.com/GB/rivet-types.php.

Xu, Y. (2006) A close look at self-piercing riveting—computer simulation is a noteworthy alternative to physical testing of joints, in The fabricator

Presz W, Cacko R (2010) Analysis of the influence of a rivet yield stress distribution on the micro-SPR joint—initial approach. Archives of Civil and Mechanical Engineering 10(4):69–75

Li, D., et al. (2010), An evaluation of quality and performance of self-piercing riveted high strength aluminium alloy AA6008 for automotive applications, in SAE World Congress. Paper No. 2010–01-0223

Iguchi, H. and Y. Ohmi (2003) Joining technologies for aluminum body-improvement of self-piercing riveting, in SAE Technical Paper 2003–01-2788. SAE International

Mori K et al (2006) Plastic joining of ultra high strength steel and aluminium alloy sheets by self piercing rivet. CIRP Ann Manuf Technol 55(1):283–286

Mori K, Abe Y, Kato T (2014) Self-pierce riveting of multiple steel and aluminium alloy sheets. J Mater Process Technol 214(10):2002–2008

Kim D-W et al (2006) Force characteristics of self-piercing riveting. Proc Inst Mech Eng B J Eng Manuf 220(8):1259–1266

Li, D., et al. (2014) The effect of setting velocity on the static and fatigue strengths of self-piercing riveted joints for automotive applications. in TMS Annual Conference

Han, L., et al. (2010) Effect of setting velocity on self-piercing riveting process and joint behaviour for automotive applications, in SAE World Congress. SAE Technical Paper 2010–01-0966

Chung CS, Kim HK (2016) Fatigue strength of self-piercing riveted joints in lap-shear specimens of aluminium and steel sheets. Fatigue Fract Eng Mater Struct 39(9):1105–1114

Hahn O, Horstmann M (2007) Mechanical joining of magnesium components by means of inductive heating—realization and capability. Mater Sci Forum 539-543:1638–1643

Durandet Y et al (2010) Laser assisted self-pierce riveting of AZ31 magnesium alloy strips. Mater Des 31(0) :S13–S16Supplement 1

Clarke, C.J., et al. (2009), Joining apparatus and method, H. Limited, Editor: Europe

Sjöström, E. (2006), Self piercing riveting and adhesive bonding of cast magnesium to ultra high strength sheet steel, Kimab, Report No.: IM-2006-501

Luo A, Lee T, Carter J (2011) Self-pierce riveting of magnesium to aluminum alloys. SAE International Journal of Materials and Manufacturing 4(1):158–165

Wang JW et al (2011) Self-piercing riveting of wrought magnesium AZ31 sheets. Journal of Manufacturing Science and Engineering-Transactions of the Asme 133(3):0310091–0310099

Miyashita Y et al (2011) Strength of adhesive aided SPR joint for AM50 magnesium alloy sheets. Procedia Engineering 10(0):2532–2537

He X et al (2015) Self-piercing riveting of similar and dissimilar metal sheets of aluminum alloy and copper alloy. Mater Des 65(0):923–933

Xing B et al (2015) Study of mechanical properties for copper alloy H62 sheets joined by self-piercing riveting and clinching. J Mater Process Technol 216(0):28–36

Zhang X et al (2016) Influence of heat treatment on fatigue performances for self-piercing riveting similar and dissimilar titanium, aluminium and copper alloys. Mater Des 97:108–117

He X et al (2015) Self-piercing riveting of similar and dissimilar titanium sheet materials. Int J Adv Manuf Technol 80(9–12):2105–2115

Pickin CG, Young K, Tuersley I (2007) Joining of lightweight sandwich sheets to aluminium using self-pierce riveting. Mater Des 28(8):2361–2365

Fratini L, Ruisi V (2009) Self-piercing riveting for aluminium alloys-composites hybrid joints. Int J Adv Manuf Technol 43(1–2):61–66

Di Franco G et al (2010) On the self-piercing riveting of aluminium blanks and carbon fibre composite panels. Int J Mater Form 3(1):1035–1038

Settineri L, Atzeni E, Ippolito R (2010) Self piercing riveting for metal-polymer joints. Int J Mater Form 3:995–998

Zhang J, Yang S (2015) Self-piercing riveting of aluminum alloy and thermoplastic composites. J Compos Mater 49(12):1493–1502

Di Franco G, Fratini L, Pasta A (2013) Analysis of the mechanical performance of hybrid (SPR/bonded) single-lap joints between CFRP panels and aluminum blanks. Int J Adhes Adhes 41(0):24–32

Fiore V et al (2013) On the mechanical behavior of BFRP to aluminum AA6086 mixed joints. Compos Part B 48(0):79–87

Gay, A., et al. (2015) Fatigue of aluminum/glass fiber reinforced polymer composite assembly joined by self-piercing riveting. in Procedia Engineering

Gay A et al (2016) Fatigue performance of a self-piercing rivet joint between aluminum and glass fiber reinforced thermoplastic composite. Int J Fatigue 83:127–134

Di Franco G, Fratini L, Pasta A (2012) Fatigue behaviour of self-piercing riveting of aluminium blanks and carbon fibre composite panels. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials Design and Applications 226(3):230–241

Di Franco G et al (2013) On the self-piercing riveting of aluminium blanks and carbon fibre composite panels. Int J Mater Form 6(1):137–144

Anon. (1990), Self-piercing rivets overcome 'impossible' joining problems, in Eureka transfers technology. p. 15

Ueda M et al (2012) Instantaneous mechanical fastening of quasi-isotropic CFRP laminates by a self-piercing rivet. Compos Struct 94(11):3388–3393

Han L, Chrysanthou A (2008) Evaluation of quality and behaviour of self-piercing riveted aluminium to high strength low alloy sheets with different surface coatings. Mater Des 29(2):458–468

Han, L., et al. (2006) , Effect of sheet material coatings on quality and strength of self-piercing riveted joints, in SAE World Congress, Paper No. 2006–01-0775

Li D et al (2012) Influence of edge distance on quality and static behaviour of self-piercing riveted aluminium joints. Mater Des 34:22–31

Li D et al (2014) The influence of fatigue on the stiffness and remaining static strength of self-piercing riveted aluminium joints. Mater Des 54:301–314

Madasamy, C., et al. (2001), Static and impact behaviour of self-pierced rivet connections in aluminium, in The ASME International Mechanical Engineering Congress and Exposition: New York. p. 73–79

Madasamy, C., et al. (2002), Experimental study on the crash performance of aluminium and steel rails, in The ASME International Mechanical Engineering Congress and Exposition: New Orleans. p. 223–231

Taylor, G. (1997) , Self-piercing riveting in automotive assembly, in The 30th International Symposium on Automotive Technology and Automotation (ISATA): Florence, Italy. p. 229–240

Porcaro R et al (2006) The behaviour of a self-piercing riveted connection under quasi-static loading conditions. Int J Solids Struct 43(17):5110–5131

Li B, Fatemi A (2006) An experimental investigation of deformation and fatigue behavior of coach peel riveted joints. Int J Fatigue 28(1):9–18

Khanna SK et al (2006) Fatigue properties and failure characterisation of self-piercing riveted 6111 aluminium sheet joints. Science and Technology of Welding & Joining 11(5):544–549

Han L et al (2006) The effect of pre-straining on the mechanical behaviour of self-piercing riveted aluminium alloy sheets. Mater Des 27(10):1108–1113

Sun, X., 9—Optimization of the strength of self-piercing rivets (SPRs), in Self-piercing riveting, A. Chrysanthou and X. Sun, Editors. 2014, Woodhead Publishing. p. 149–170.

Stephens, E.V. (2014) , 2—Mechanical strength of self-piercing riveting (SPR), in Self-piercing riveting, A. Chrysanthou and X. Sun, Editors, Woodhead Publishing. p. 11–32

Li D et al (2012) Influence of die profiles and cracks on joint buttons on the joint quality and mechanical strengths of high strength aluminium alloy joint. Adv Mater Res 548:398–405

Han L et al (2005) The effect of breakthrough on the behaviour of self-piercing riveted aluminium 5754 - HSLA joints. Transactions of Society of Automotive Engineers of Japan 36(5):181–186

Fu M, Mallick PK (2003) Fatigue of self-piercing riveted joints in aluminum alloy 6111. Int J Fatigue 25(3):183–189

Blacket, S. (1995) , The self pierce riveting process comes of age, in Proceedings of the materials in welding and joining conference, Institute of Metals and Materials Australasia. p. 149–154

Riches, S.T., et al. (1995) , Advanced joining technologies for lightweight vehicle manufacture, in Proceedings of the materials for lean weight vehicles conference, Institute of Materials. p. 137–146

Krause, A.R. and A.R.A. Chernenkoff (1995) , A comparative study of the fatigue behaviour of spot welded and mechanically fastened aluminium joints, in SAE World Congress, Paper No. 950710

Mizukoshi H, Okada H (1997) Fatigue properties of mechanical fastening joints. Mater Sci Forum 242:231–238

Briskham, P., et al. (2006) , Comparison of self-pierce riveting, resistance spot welding and spot friction joining for aluminium automotive sheet, in SAE Technical Paper 2006–01-0774, SAE International

Han L, Thornton M, Shergold M (2010) A comparison of the mechanical behaviour of self-piercing riveted and resistance spot welded aluminium sheets for the automotive industry. Mater Des 31(3):1457–1467

Booth, G.S., et al. (2000), Self-piercing riveted joints and resistance spot welded joints in steel and aluminium, in SAE World Congress, Paper No. 2000–01-2681

Galtier, A. and J.-N. Gacel, Fatigue behavior of mechanical joining for HSS grades, in SAE Technical Paper 2002–01-1998. 2002, SAE International.

Westgate, S. (2004), The resistance spot welding of high and ultra-high strength steels, in the 3rd International Seminar on Advances in Resistance Welding: Berlin.

Dannbauer H et al (2006) Development of a model for the stiffness and life time prediction of self piercing riveted joints in automotive components. Materialpruefung/Materials Testing 48(11–12):576–581

Svensson, L.-E. and J.K. Larsson (2002) , Welding and joining of high-performance car bodies, in trends in welding research: proceedings of the 6th international Conference, ASM International. p. 787–792

Westgate, S.A. and M.C. Whittaker (1994) , Press joining and self piercing riveting for sheet joining-joint formation and mechanical properties, TWI Report 492/1994

Razmjoo, G.R. and S.A. Westgate (1999) , Fatigue properties of clinched, self piercing riveted and spot welded joints in steel and aluminium alloy sheet, TWI Report 680/1999

Mori K, Abe Y, Kato T (2012) Mechanism of superiority of fatigue strength for aluminium alloy sheets joined by mechanical clinching and self-pierce riveting. J Mater Process Technol 212(9):1900–1905

Blundell, N., et al. (2005) , A comparative study between self pierce riveting and spot friction joining, in JSAE Annual Congress : Japan, paper No.: 20055417.

Han L, Chrysanthou A, O'Sullivan JM (2006) Fretting behaviour of self-piercing riveted aluminium alloy joints under different interfacial conditions. Mater Des 27(3):200–208

Li D et al (2012) Influence of rivet to sheet edge distance on fatigue strength of self-piercing riveted aluminium joints. Mater Sci Eng A 558:242–252

Li D et al (2013) Influence of rivet tip geometry on the joint quality and mechanical strengths of self-piercing riveted aluminium joints. Mater Sci Forum 765:746–750

Han L, Chrysanthou A, Young KW (2007) Mechanical behaviour of self-piercing riveted multi-layer joints under different specimen configurations. Mater Des 28(7):2024–2033

Sun X, Stephens EV, Khaleel MA (2007) Fatigue behaviors of self-piercing rivets joining similar and dissimilar sheet metals. Int J Fatigue 29(2):370–386

Zhao L et al (2015) Influence of sheet thickness on fatigue behavior and fretting of self-piercing riveted joints in aluminum alloy 5052. Mater Des 87:1010–1017

Agrawal, H., et al. (2003) , Fatigue life of self pierced rivets (SPR) in car body, in SAE Technical Paper − 01-0914. 2003, SAE International.

Iyer K et al (2005) Fatigue of single- and double-rivet self-piercing riveted lap joints. Fatigue & Fracture of Engineering Materials & Structures 28(11):997–1007

Jin, Z. and P.K. Mallick (2002), Enhancement of fatigue life of self-piercing riveted joints by coining, in The ASME International Mechanical Engineering Congress and Exposition : New Orleans. p. 417–430

Eckstein, J., et al. (2007), Experimental and numerical investigations to extend the process limits in self-pierce riveting, in 10th ESAFORM conference on Material Froming, E. Cueto and F. Chinesta, Editors. p. 279–284.

Huang L et al (2016) Fatigue and fretting of mixed metal self-piercing riveted joint. Int J Fatigue 83:230–239

Han, L., et al. (2002) , Self-pierce riveting—a new way for joining structures, in Structures pressure vessels and piping conference, PVP2002–1495. p. 123–127.

Han L et al (2006) Characterization of fretting fatigue in self-piercing riveted aluminium alloy sheets. Fatigue & Fracture of Engineering Materials & Structures 29(8):646–654

Chen YK et al (2003) Fretting wear in self-piercing riveted aluminium alloy sheet. Wear 255(7–12):1463–1470

Iyer, K., et al. (2002), Fatigue and fretting of self-piercing riveted joints, in Proceedings of IMECE. ASME: New Orleans, Louisiana. p. 401–415

Sun, X., E. Vela, and M.A. Khaleel (2002) Analytical strength estimator for self-piercing rivets, Battelle Pacific Northwest National Laboratory, PNNL technical report

Sun X, Khaleel MA (2005) Strength estimation of self-piercing rivets using lower bound limit load analysis. Sci Technol Weld Join 10(5):624–635

Sun X, Khaleel MA (2005) Performance optimization of self-piercing rivets through analytical rivet strength estimation. J Manuf Process 7(1):83–93

Haque R, Durandet Y (2016) Strength prediction of self-pierce riveted joint in cross-tension and lap-shear. Mater Des 108:666–678

Lee MH, Kim HY, Oh SI (2006) Crushing characteristic of double hat-shaped member of different materials joined by adhesive bonding and self-piercing rivet. Int J Automot Technol 7(5):565–570

Lee M-H, Kim H-Y, Oh S-I (2006) Crushing test of double hat-shaped members of dissimilar materials with adhesively bonded and self-piercing riveted joining methods. Thin-Walled Struct 44(4):381–386

Sun X, Khaleel MA (2007) Dynamic strength evaluations for self-piercing rivets and resistance spot welds joining similar and dissimilar metals. International Journal of Impact Engineering 34(10):1668–1682

Porcaro R et al (2004) Joining of aluminium using self-piercing riveting: testing, modelling and analysis. International Journal of Crashworthiness 9(2):141–154

Porcaro R et al (2008) Crashworthiness of self-piercing riveted connections. International Journal of Impact Engineering 35(11):1251–1266

Wood PKC et al (2011) A model to describe the high rate performance of self-piercing riveted joints in sheet aluminium. Mater Des 32(4):2246–2259

Westerberg, C. (2002) , Finite element simulation of crash testing of selfpiercing rivet joints, peel specimen, in Structural Mechanics, LUND University: LTH

Tang, D.X., B. Barthelemy, and H. Yuan (2002) , Self-pierced rivet (SPR) modeling in aluminum structure crash analysis, in Proceedings of IMECE. , ASME: New Orleans, Louisiana. p. 207–222

Hutchings MT, Withers PJ, Holden TM et al (2005) Introduction to the characetrization of residual stress by neutron diffraction. Taylor & Francis, Boca Raton, FL

Withers PJ et al (2008) Recent advances in residual stress measurement. International Journal of Pressure Vessles and piping 85(3):118–127

Haque R et al (2012) Feasibility of measuring residual stress profile in different self-pierce riveted joints. Science and Technology of Welding & Joining 17(1):60–68

Khezri R, Melander A (2006) New technology for self piercing riveting of TRIP800 in 1 + 1 and 1 + 2 mm sheet thickness. Swedish Institute for Metal Research, Stockholm

Khezri R, Melander A (2003) Simulation of self piercing riveting of TRIP800 sheet steel in 1 + 1 mm thickness. Swedish Institute for Metals Research, Stockholm

Haque R et al (2013) Optimising parameters for meaningful measurement of residual strain by neutron diffraction in self-pierce riveted joints. Sci Technol Weld Join 18(6):492–499

Weber, A. (2004) , A new look at an old technology, in Assembly. p. 38–45

Hahn O, Wibbeke T-M (2005) Application of low-heat hybrid joining technologies for the joining of thin-walled sheet materials. Welding & Cutting 4(4):208–214

Hahn O, Meschut G, Peetz A (1999) Mechanical properties of punch-riveted and adhesive-bonded aluminium sheets. Welding & Cutting 51(7):E130–E134

Moroni F, Pirondi A, Kleiner F (2010) Experimental analysis and comparison of the strength of simple and hybrid structural joints. Int J Adhes Adhes 30(5):367–379

Westgate, S.A. and G.R. Razmjoo (1999) , Static and fatigue performance of mechanically fastened and hybrid joints in steel metals, TWI Report 691/1999

Cai W, Wang PC, Yang W (2005) Assembly dimensional prediction for self-piercing riveted aluminum panels. Int J Mach Tools Manuf 45(6):695–704

Huang H et al (2007) Distortion analysis for self-piercing riveting of aluminium alloy sheets. Sci Technol Weld Join 12(1):73–78

Fan, X. and I. Masters2006, Dimensional variation in self-piercing riveting, in SAE Technical Paper 2006-01-0776, SAE International

Masters I et al (2012) Modelling distortion induced in an assembly by the self piercing rivet process. Proceedings of the Institution of Mechanical Engineers Part B-Journal of Engineering Manufacture 226(B2):300–312

Calabrese L et al (2013) Durability on alternate immersion test of self-piercing riveting aluminium joint. Mater Des 46:849–856

Howard, R.M. and S.P. Sunday (1983) , The corrosion performance of steel self-piercing rivets when used with aluminum components, in SAE World Congress, Paper No. 831816.

Ioannou, J. (2009) , Mechanical behaviour and corrosion of interstitial-free steel to aluminium alloy self-piercing riveted joints, PhD thesis, in School of Engineering and Technology, University of Hertfordshire, UK

Calabrese L et al (2015) Failure behaviour of SPR joints after salt spray test. Eng Struct 82:33–43

King, R.P. (1997), Analysis and quality monitoring self-pierce riveting process, in PhD thesis, University of Hertfordshire

Han, L., et al. (2007) , An evaluation of NDT for self-pierce riveting, in SAE World Congress, Paper No. 2007–01-1364

Stepinski, T. (2006) Assessing quality of self-piercing rivets using ultrasound. in European Conference on Non-Destructive Testing. Berlin, Germany

Gay, A., et al. (2016) , Non-destructive inspection of initial defects of PA6.6-GF50/aluminum self-piercing riveted joints and damage monitoring under mechanical static loading. International Journal of Damage Mechanics

Casalino G, Rotondo A, Ludovico A (2008) On the numerical modelling of the multiphysics self piercing riveting process based on the finite element technique. Adv Eng Softw 39(9):787–795

Khezri, R., E. Sjöström, and A. Melander (2000) , Self-piercing riveting of high strength steel, Swedish Institute for Metal Research: Report No.: IM-2000-554

Porcaro R et al (2006) Self-piercing riveting process: an experimental and numerical investigation. J Mater Process Technol 171(1):10–20

Carandente M et al (2016) Improvements in numerical simulation of the SPR process using a thermo-mechanical finite element analysis. J Mater Process Technol 236:148–161

Mucha J (2011) A study of quality parameters and behaviour of self-piercing riveted aluminium sheets with different joining conditions. Strojniski Vestnik-Journal of Mechanical Engineering 57(4):323–333

Kato T, Abe Y, Mori K (2007) Finite element simulation of self-piercing riveting of three aluminium alloy sheets. Key Eng Mater 340-341:1461–1466

Abe Y, Kato T, Mori K (2009) Self-piercing riveting of high tensile strength steel and aluminium alloy sheets using conventional rivet and die. J Mater Process Technol 209(8):3914–3922

Krishnappa, U.S. (2004) , Numerical investigation of self-piercing riveted dual layer joint, in Department of Mechanical Engineering,, Master thesis, Wichita State University, India.

Atzeni E, Ippolito R, Settineri L (2007) FEM modeling of self-piercing riveted joint. Key Eng Mater 344:655–662

Bouchard PO, Laurent T, Tollier L (2008) Numerical modeling of self-pierce riveting—from riveting process modeling down to structural analysis. J Mater Process Technol 202(1–3):290–300

Porcaro R et al (2006) An experimental investigation on the behaviour of self-piercing riveted connections in aluminium alloy AA6060. International Journal of Crashworthiness 11(5):397–417

Hanssen AG et al (2010) A large-scale finite element point-connector model for self-piercing rivet connections. European Journal of Mechanics - A/Solids 29(4):484–495

Sommer, S. and J. Maier (2011) , Failure modelling of a self piercing riveted joint using LS-Dyna, in 8th European LS-DYNA Conference: Strasbourg, France.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Li, D., Chrysanthou, A., Patel, I. et al. Self-piercing riveting-a review. Int J Adv Manuf Technol 92, 1777–1824 (2017). https://doi.org/10.1007/s00170-017-0156-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0156-x