Abstract

Limited by strength of electromagnetic coil, discharging energy of capacitor bank and some other auxiliary tools, electromagnetic forming (EMF) researches are mainly focused on regular size specimens. This paper demonstrates forming procedure of a large size AA2524-T3 sheet specimen with one-dimensional curvature, which expands application of electromagnetic force and intends to explore a new forming technology for aircraft skin manufacturing. It is based on the superposition of shallow local dome-shaped and bowl-shaped deformations which are generated by a coaction of electromagnetic driving force and punch matrix restraining. The results show that the sheet in size of 1840 mm × 810 mm × 2.5 mm is formed to be a macroscopically one-dimensional curved specimen. Curvature radius of the specimen varies from 6115.4 to 6328.3 mm. The maximum deflection of the specimen reaches 79.4 mm. Feasibility of this method in forming specimen with large size and one-dimensional curvature is verified.

Similar content being viewed by others

References

Kiliclar Y, Demir OK, Engelhardt M, Rozgić M, Vladimirov IN, Wulfinghoff S, Weddeling C, Gies S, Klose C, Reese S, Tekkaya AE, Maier HJ, Stiemer M (2016) Experimental and numerical investigation of increased formability in combined quasi-static and high-speed forming processes. J Mater Process Technol 237:254–269. doi:10.1016/j.jmatprotec.2016.06.007

Maris C, Hassannejadasl A, Green DE, Cheng J, Golovashchenko SF, Gillard AJ, Liang Y (2016) Comparison of quasi-static and electrohydraulic free forming limits for DP600 and AA5182 sheets. J Mater Process Technol 235:206–219. doi:10.1016/j.jmatprotec.2016.04.028

Seth M, Vohnout VJ, Daehn GS (2005) Formability of steel sheet in high velocity impact. J Mater Process Technol 168:390–400. doi:10.1016/j.jmatprotec.2004.08.032

Golovashchenko SF (2007) Material formability and coil design in electromagnetic forming. J Mater Eng Perform 16:314–320. doi:10.1007/s11665-007-9058-7

Xu J, Yu H, Cui J, Li C (2013) Formability of AZ31 magnesium alloy sheets during magnetic pulse bulging. Mater Sci Eng A 569:150–158. doi:10.1016/j.msea.2013.01.016

Li F, Mo J, Li J, Huang L, Zhou H (2013) Formability of Ti–6Al–4V titanium alloy sheet in magnetic pulse bulging. Mater Des 52:337–344. doi:10.1016/j.matdes.2013.05.064

Rajendran AM, Fyfe IM (1982) Inertia effects on the ductile failure of thin rings. J Appl Mech 49:31–36

Regazzoni G, Johnson JN, Follansbee PS (1986) Theoretical study of the dynamic tensile test. J Appl Mech 53:519–528

Balanethiram VS, Daehn GS (1994) Hyperplasticity: increased forming limits at high workpiece velocity. Scr Metall Mater 30:515–520. doi:10.1016/0956-716X (94) 90613-0

Altynova M, Hu X, Daehn GS (1996) Increased ductility in high velocity electromagnetic ring expansion. Metall Mater Trans A 27A:1837–1844. doi:10.1007/bf02651933

Hu X, Daehn GS (1996) Effect of velocity on flow location in tension. Acta Metall 44(3):1020–1033

Golovashchenko S (1999) Numerical and experimental results on pulsed tubes calibration. Paper presented at the The TMS annual meeting, San Diego,

Daehn GS, Vohnout VJ, Datta S (2011) Hyperplastic forming: process potential and factors affecting formability. MRS Proc:601. doi:10.1557/proc-601-247

Imbert JM, Winkler SL, Worswick MJ, Golovashchenko S (2004) Formability and damage in electromagnetically formed AA5754 and AA6111. Paper presented at the 1st International Conference on High Speed Forming, Dortmund,

Imbert JM, Winkler SL, Worswick MJ, Oliveira DA, Golovashchenko S, 2004. Numerical study of damage evolution and failure in an electromagnetic corner fill operation. In: NUMIFORM , 2004. p 1833. doi:10.1063/1.1766799

Boyd JMSI (2005) Increased formability and the effects of the tool/sheet interaction in electromagnetic forming of aluminum alloy sheet. University of Waterloo, Waterloo

Imbert JM, Winkler SL, Worswick MJ, Oliveira DA, Golovashchenko S (2005) The effect of tool–sheet interaction on damage evolution in electromagnetic forming of aluminum alloy sheet. J Eng Mater Technol 127:145. doi:10.1115/1.1839212

Lewandowski JJ, Lowhaphandu P (1998) Effects of hydrostatic pressure on mechanical behaviour and deformation processing of materials. Int Mater Rev 43(4):145–187. doi:10.1179/imr.1998.43.4.145

Windholtz TN (2012) Plane-strain formability of sheet metal at high velocity. The Ohio State University, Ohio

Zener C, Hollomon JH (1944) Effect of strain rate upon plastic flow of steel. J Appl Phys 15:22–32. doi:10.1063/1.1707363

Oosterkamp LD, Ivankovic A, Venizelos G (2000) High strain rate properties of selected aluminium alloys. Mater Sci Eng A 278:225–235

Hadianfard MJ, Smerd R, Winkler S, Worswick M (2008) Effects of strain rate on mechanical properties and failure mechanism of structural Al–Mg alloys. Mater Sci Eng A 492:283–292. doi:10.1016/j.msea.2008.03.037

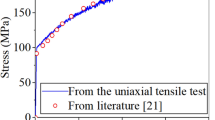

Chen Y, Clausen AH, Hopperstad OS, Langseth M (2009) Stress–strain behaviour of aluminium alloys at a wide range of strain rates. Int J Solids Struct 46:3825–3835. doi:10.1016/j.ijsolstr.2009.07.013

Iriondo E, Gonzalez B, Gutierrez M, Vonhout V, Daehn G, Hayes B, 2006 Electromagnetic springback reshaping. In: 2nd International Conference on High Speed Forming,.

Iriondo E, Alcaraz JL, Daehn GS, Gutiérrez MA, Jimbert P (2013) Shape calibration of high strength metal sheets by electromagnetic forming. J Manuf Process 15:183–193. doi:10.1016/j.jmapro.2013.01.007

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming—a review. J Mater Process Technol 211:787–829. doi:10.1016/j.jmatprotec.2010.12.012

VanBenthysen R, Thibaudeau E, Kinsey BL (2013) Effect of specimen planar area on electromagnetic flanging. J Manuf Process 15:194–200. doi:10.1016/j.jmapro.2013.01.005

Cui X, Mo J, Li J, Zhao J, Zhu Y, Huang L, Li Z, Zhong K (2014) Electromagnetic incremental forming (EMIF): a novel aluminum alloy sheet and tube forming technology. J Mater Process Technol 214:409–427. doi:10.1016/j.jmatprotec.2013.05.024

Cui X, Li J, Mo J, Fang J, Zhu Y, Zhong K (2015) Investigation of large sheet deformation process in electromagnetic incremental forming. Mater Des 76:86–96. doi:10.1016/j.matdes.2015.03.060

Long A, Wang W, Fang C, Wu X, Wan M (2016) A novel forming method of aluminum sheet based on superposition principle of electromagnetic local forming. J Phys Conf Ser:734. doi:10.1088/1742-6596/734/3/032002

Noh H, Song W, Kang B, Kim J (2014) Two-step electromagnetic forming process using spiral forming coils to deform sheet metal in a middle-block die. Int J Adv Manuf Technol 76:1691–1703. doi:10.1007/s00170-014-6392-4

Li M, Cai Z, Sui Z, Yan Q (2002) Multi-point forming technology for sheet metal. J Mater Process Technol 129:333–338

Zhang M, Tian X, Lv H (2016) Press bend forming analysis based on DTPMS for butt joints on aircraft panels. Procedia CIRP 56:279–283. doi:10.1016/j.procir.2016.10.083

Wang Y, Li M, Liu H, Xing J (2014) Finite element simulation of multi-gripper flexible stretch forming. Procedia Engineering 81:2445–2450. doi:10.1016/j.proeng.2014.10.348

Feng Z, Champliaud H (2011) Three-stage process for improving roll bending quality. Simul Model Pract Theory 19:887–898. doi:10.1016/j.simpat.2010.11.006

Miao HY, Demers D, Larose S, Perron C, Lévesque M (2010) Experimental study of shot peening and stress peen forming. J Mater Process Technol 210:2089–2102. doi:10.1016/j.jmatprotec.2010.07.016

Zhan L, Lin J, Dean TA (2011) A review of the development of creep age forming: experimentation, modelling and applications. Int J Mach Tools Manuf 51:1–17. doi:10.1016/j.ijmachtools.2010.08.007

Shaw JS, Johnson NA (1998) Balanced electromagnetic peening. US Patent 5813265,

Dyno JR, Yushanov SP (2012) System and method for electromagnetic pulse surface treatment. US Patent US8253081B2,

The Aluminum Association (2015) International alloy designations and chemical composition limits for wrought aluminum and wrought aluminum alloys. http://www.aluminum.org/sites/default/files/TEAL_1_OL_2015.pdf.

Fenton GK, Daehn GS (1998) Modeling of electromagnetically formed sheet metal. J Mater Process Technol 75:6–16

Takatsu N, Kato M, Sato K, Tobe T (1988) High speed forming of metal sheets by electromagnetic force. The Japan Society of Mechanical Engineers 31(1):142–148

Kuo C, You J, Hwang S (2011) Temperature effect on electromagnetic forming process by finite element analysis. International Journal of Applied Electromagnetics and Mechanics 35:25–37. doi:10.3233/jae-2011-1319

Bruschi S, Altan T, Banabic D, Bariani PF, Brosius A, Cao J, Ghiotti A, Khraisheh M, Merklein M, Tekkaya AE (2014) Testing and modelling of material behaviour and formability in sheet metal forming. CIRP Ann Manuf Technol 63:727–749. doi:10.1016/j.cirp.2014.05.005

Li F, Mo J, Zhou H, Fang Y (2012) 3D numerical simulation method of electromagnetic forming for low conductive metals with a driver. Int J Adv Manuf Technol 64:1575–1585. doi:10.1007/s00170-012-4124-1

Dutta K, Ray KK (2012) Ratcheting phenomenon and post-ratcheting tensile behaviour of an aluminum alloy. Mater Sci Eng A 540:30–37. doi:10.1016/j.msea.2012.01.024

Kreethi R, Verma P, Dutta K (2015) Influence of heat treatment on ratcheting fatigue behavior and post ratcheting tensile properties of commercial aluminum. Trans Indian Inst Metals 68(2):229–237. doi:10.1007/s12666-014-0449-9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Long, A., Wan, M., Wang, W. et al. Electromagnetic superposed forming of large-scale one-dimensional curved AA2524-T3 sheet specimen. Int J Adv Manuf Technol 92, 25–38 (2017). https://doi.org/10.1007/s00170-017-0127-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0127-2