Abstract

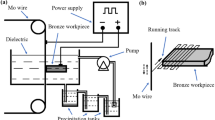

In this study, an experimental target plate jet mill was designed and used to produce CuSn10 bronze powder from its machining chips. Taguchi method with an L9 orthogonal array was used as experimental design to determine the optimum conditions for the pulverization of the machining chips via jet milling. The effect of process variables including nozzle to target distance, impact angle, and air pressure were investigated. The optimum conditions were found to be 8 cm for nozzle to target distance, a 90° angle between nozzle and target, and an air pressure of 7 bar. Repeated impact cycles lead to the production of finer and more rounded particles, although the rate of size reduction was reduced. The jet-milled powder did not contain any contamination, and the amount of the surface oxide of the jet-milled powder was even lower than that of the initial machining chips. Investigation of the fragmentation of particles revealed that the initial machining cracks were the main sites for breakage during pulverization. In addition, the delta phase in the microstructure of the bronze alloy plays an important role in the propagation of pre-existing cracks as well as creating new cracks.

Similar content being viewed by others

References

Mandatsy Moungomo JB, Nganga-Kouya D, Songmene V, Kouam J, Kenné JP (2016) Machinability study of recycled aluminum cans and machining chips. Int J Adv Manuf Technol 87(9):2551–2566

Guluzade R, Avcı A, Turan Demirci M, Faruk Erkendirci Ö (2013) Fracture toughness of recycled AISI 1040 steel chip reinforced AlMg1SiCu aluminum chip composites. Mater Des 52:345–352

Emadi Shaibani M, Ghambari M (2011) Characterization and comparison of gray cast iron powder produced by target jet milling and high energy ball milling of machining scraps. Powder Technol 212:278–283

Canakci A, Varol T (2015) A novel method for the production of metal powders without conventional atomization process. J Clean Prod 99:312–319

Lela B, Krolo J, Jozi S (2016) Mathematical modeling of solid-state recycling of aluminum chips. Int J Adv Manuf Technol 87(1):1125–1133

Emadi Shaibani M, Eshraghi N, Ghambari M (2013) Sintering of grey cast iron powder recycled via jet milling. Mater Des 47:174–178

Sikong L, Kooptanond K, Morasut N, Pongprasert T (2008) Fine grinding of brittle minerals and materials by jet mill. Songklanakarin J Sci Technol 30(3):377–384

Djoki M, Djuri J, Solomun L, Kachrimanis K, Djuric Z, Ibri S (2014) The influence of spiral jet-milling on the physicochemical properties of carbamazepine form III crystals: quality by design approach. Chem Eng Res Des 92:500–508

Afshari E, Ghambari M (2016) Characterization of pre-alloyed tin bronze powder prepared by recycling machining chips using jet milling. Mater Des 103:201–208

Tabernero I, Lamikiz A, Ukar E, López de Lacalle LN, Angulo C, Urbikain G (2010) Numerical simulation and experimental validation of powder flux distribution in coaxial laser cladding. J Mater Process Technol 210(15):2125–2134

Alberdi A, Rivero A, López de Lacalle LN (2011) Experimental study of the slot overlapping and tool path variation effect in abrasive waterjet milling. J Manuf Sci Eng 133(3):034502–034502-4

Tuunila R, Nystrom L (1998) Effects of grinding parameters on product fineness in jet mill grinding. Miner Eng 1:1089–1094

Mebtoul M, Large JF, Guigon P (1996) High velocity impact of particles on a target—an experimental study. Int J Miner Process 44-45:77–91

Tasirin SM, Geldart D (1999) Experimental investigation on fluidized bed jet grinding. Powder Technol 105:337–341

Zugner S, Marquardt K, Zimmermann I (2006) Influence of nano mechanical crystal properties on the comminution process of particulate solids in spiral jet mills. Eur J Pharm Biopharm 62:194–201

De Vegt O, Vromans H, Toonder J, Van der Voort MK (2009) Influence of flaws and crystal properties on particle fracture in a jet mill. Powder Technol 191:72–77

Neikov OD, Naboychenko SS, Dowson G (2009) Handbook of non ferrous metal powders, technologies and applications, 1st edn. Elsevier, Oxford

Canakci A, Varol T, Cuvalci H, Erdemir F, Ozkaya S, Yalcin ED (2014) Synthesis of novel CuSn10 -graphite nanocomposite powders by mechanical alloying. Micro Nano Lett 9:109–112

Scudino S, Unterdörfer C, Prashanth KG, Attar H, Ellend N, Uhlenwinkel V, Eckert J (2015) Additive manufacturing of Cu–10Sn bronze. Mater Lett 156:202–204

Yilbas BS, Akhtar SS, Karatas C (2013) Laser nitriding of the surface of phosphor bronze. Int J Adv Manuf Technol 65:1553–1565

Canakci A, Varol T, Cuvalci H, Erdemir F, Ozkaya S (2014) Development and characterization of bronze-Cr-Ni composites produced by powder metallurgy. Sci Eng Compos Mater. doi:10.1515/secm-2013-0262

Annual Book of ASTM Standards; ASTM Designation: E 276–98 (2004) American Society for Testing and Materials, West Conshohocken, PA

Vogel L, Peukert W (2002) Characterization of grinding-relevant particle properties by inverting a population balance model. Part Part Syst Charact 19:149–157

Vogel L, Peukert W (2003) Breakage behavior of different materials-construction of a mastercurve for the breakage probability. Powder Technol 129:101–110

Khajavi A, Kolahan F, Esmaelzade A (2014) A Taguchi approach for optimization of process parameters in water jet cleaning process. IJST Transactions of Mechanical Engineering 38:97–104

Ghani JA, Choudhury IA, Hassan HH (2004) Application of Taguchi method in the optimization of end milling parameters. J Mater Process Technol 145:84–92

Karimi S, Ataie A (2016) Characterization of mechanothermally processed nanostructured ZnO. Int J Miner Metal Mater 23(5):588–594

Roy RK (1990) A primer on the Taguchi method. Van Nostrand Reinhold, New York

Eskin D, Voropayev S (2004) An engineering model of particulate friction in accelerating nozzles. Powder Technol 145:203–212

Prasad BK, Yegneswaran AH, Patwardhan AK (1997) Influence of the nature of microconstituents on the tensile properties of a zinc-based alloy and a leaded-tin bronze at different strain rates and temperatures. J Mater Sci 32:1169–1175

Scott DA (1991) Metallography and microstructure of ancient and historic metals. Tien Wah Press, Singapore

Lecoq O, Guigon P, Pons MN (1999) A grindability test to study the influence of material processing on impact behavior. Powder Technol 105:21–29

Bokii YF (1982) Purification of metal powders from oxide films in a jet mill. Powder Metall Met Ceram 21(2):81–84

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Afshari, E., Ghambari, M. & Abdolmalek, H. Production of CuSn10 bronze powder from machining chips using jet milling. Int J Adv Manuf Technol 92, 663–672 (2017). https://doi.org/10.1007/s00170-017-0126-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0126-3