Abstract

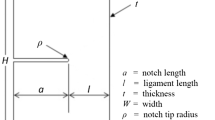

The present work proposes a new numerical approach based on the derivation method of Bridgman to determine (K IC ) of galvanized steel sheets. The method relies on a fracture analysis numerical code “Franc2D,” which permits to simulating the initiation and propagation of a crack on grooved tensile specimens. First, the stress intensity factor is obtained while the crack is propagating and then (K IC ) is determined from the fitting curves of the stress intensity factor (K I ) to crack length (a) plot through mathematical transformations. The results are validated by comparing them to those obtained through the experimental approach using Vickers hardness based IEF engineering models. The relative values of (K IC ) are admissible and acceptable with a coefficient of variation of 14% for a large range of groove radius. Hence, the present numerical simulation can be fairly used in order to reduce time consuming and avoid costly experimental mechanical tests.

Similar content being viewed by others

References

Coni N, Gipiela ML, D’Oliveira ASCM, Marcondes PVP (2009) Study of the mechanical properties of the hot dip galvanized steel and galvalume. J of the Braz Soc of Mech Sci and Eng 4:319–326

Seré PR, Culcasi JD, Elsner CI, Di Sarli AR (1999) Relationship between texture and corrosion resistance in hot-dip galvanized steel sheets. Surf Coat Technol 122:143–149

Cheng JG, Zhang J, Chu CC, Zhe J (2005) Experimental study and computer simulation of fracture toughness of sheet metal after laser forming. Int J Adv Manuf Technol 26:1222–1230

Shih HC, Hsu JW, Sun CN, Chung SC (2002) The lifetime assessment of hot-dip 5% Al-Zn coatings in chloride environments. Surf Coat Technol 150:70–75

Carbucicchio M, Ciprian R, Ospitali F, Palombarini G (2008) Morphology and phase composition of corrosion products formed at the zinciron interface of a galvanized steel. Corros Sci 50:2605–2613

Hayat F, Sevim I (2012) The effect of welding parameters on fracture toughness of resistance spot-welded galvanized DP600 automotive steel sheets. Int J Adv Manuf Technol 58:1043–1050

Asgari A, Toroghinejad MR, Golozar MA (2009) Effect of coating thickness on modifying the texture and corrosion performance of hot-dip galvanized coatings. Curr Appl Phys 9:59–66

Kim H, Sung J, Goodwin FE, Altan T (2008) Investigation of galling in forming galvanized advanced high strength steels (AHSSs) using the twist compression test (TCT). J Mater Process Technol 205:459–468

Ploypech S, Boonyongmaneerat Y, Jearanaisilawong P (2012) Crack initiation and propagation of galvanized coatings hot-dipped at 4500C under bending loads. Surf Coat Technol 206:3758–3763

Lai WJ, Pan J (2014) Stress intensity factor solutions for adhesive-bonded lap-shear specimens of magnesium and steel sheets with and without kinked cracks for fatigue life estimations. Eng Fract Mech 131:454–470

Byun TS, Kim SH, Lee BS, Kim IS, Hong JH (2000) Estimation of fracture toughness transition curves of RPV steels from ball indentation and tensile test data. J Nucl Mater 277:263–273

Byun TS, Kim JW, Hong JH (1998) A theoretical model for determination of fracture toughness of reactor pressure vessel steels in the transition region from automated ball indentation test. J Nucl Mater 252:187–194

Haggag FM, Byun TS, Hong JH, Miraglia PQ, Murty KL (1998) Indentation-energy-to-fracture (IEF) parameter for characterization of DBTT in carbon steels using nondestructive automated ball indentation (ABI) technique. Scripta Matetialia 38(4):645–651

Khandelwal HK, Sharma K, Chhibber R (2012) Mechanical property estimation of similar weld using ball indentation technique. J Miner Mater Charact Eng 11:1095–1100

Mohammadi AH, Naderi M, Iranmanesh M (2011) Fracture toughness evaluation of 3Cr-1Mo steel from Vickers indentation and tensile test data. Procedia Engineering 10:228–235

Bridgman PW (1952) Studies in large plastic flow and fracture. McGraw-Hill.

Bai Y (2008) Effect of loading history on necking and fracture. PhD thesis, Massachusetts Institute of Technology, USA

Holloman JH (1945) Tensile deformation. Trans AIME 162:268–290

ASTM E1921-98 (1998) Test method for the determination of reference temperature, T0, for ferritic steels in the transition range

Moussa C, Bartier O, Mauvoisin G, Delattre G, Hernot X (2013) Revue bibliographique sur la caractérisation mécanique des matériaux utilisant la déformation représentative en indentation sphérique. Matériaux et technique 101:302

Bektes M, Uzun O, Aktȕrk S, Ekinci AE, Uçar N (2004) Vickers Microhardness studies of Fe-Mn binary alloys. Chin J Phys 42(6):733–739

Davis JR (2004) Tensile testing, second edition. ASM International 13:226–227

Kut S (2010) A simple method to determine ductile fracture strain in a tensile test of plane specimens. Metalurgija 49(4):295–299

Dzik EJ, Lajtai EZ (1996) Primary fracture propagation from circular cavities loaded in compression. Int J Fract 79:49–64

Cendon DA, Galvez JC, Elices M, Planas J (2000) Modelling the fracture of concrete under mixed loading. Int J Fract 103:293–310

Carpinteri A, Invernizzi S (2005) Numerical analysis of the cutting interaction between indenters acting on disordered materials. Int J Fract 131:143–154

Lim WK (2011) Determination of second-order term coefficients for the inclined crack in orthotropic plate using singular finite elements. Int J Fract 168:125–132

Seifi R, Eshraghi M (2013) Effects of mixed-mode overloading on the mixed-mode I + II fatigue crack growth. Arch Appl Mech 83:987–1000

Al-Mukhtar AM (2016) Mixed-mode crack propagation in cruciform joint using Franc2D. J Fail Anal And Preven, Tools and techniques, CrossMark

Wawrzynek P, Ingraffea A (1994) Franc2D: a two-dimensional crack propagation simulator. Tutorial and User’s Guide, Version 2.7, NASA contractor report 4572

Iesulauro E (1995) Franc2D/L A crack propagation simulation for plane layered structures. Version 1.5 user’s guide. Cornell University, Ithaca, New York

Iesulauro E (2002) Franc2D/L A crack propagation simulator for plane layered materials. Cornell University, Ithaca, New York

Wawrzynek P, Martha L (1997) CASCA: a simple 2-D mesh generator, version 1.4 user’s guide. Cornell University, Ithaca, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Daoud, L., Belhamzaoui, A. & Amirat, A. Comparison between IEF model and numerical method based on the derivation method of Bridgman to evaluating fracture toughness in galvanized steel sheet. Int J Adv Manuf Technol 92, 569–581 (2017). https://doi.org/10.1007/s00170-017-0097-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0097-4