Abstract

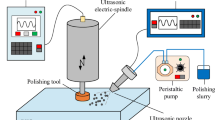

The chemical mechanical polishing (CMP) is widely used to polish hard and brittle materials. However, it is difficult for conventional CMP to achieve high material removal rate (MRR) and high surface quality while polishing of hard and brittle materials such as monocrystalline silicon. Therefore, ultrasonic elliptical vibration (UEV) is employed to aid conventional CMP in our research, which combines the functions of conventional CMP and ultrasonic machining. In the ultrasonic elliptical vibration-aided chemical mechanical polishing (UEV-CMP) experimental setup developed by us, the workpiece attached on the ultrasonic vibrator can vibrate simultaneously in both horizontal and vertical directions during CMP. It is found that the ultrasonic elliptical vibration can effectively increase the MRR while maintaining surface quality in conventional CMP. The possible mechanism in UEV-CMP is firstly analyzed chemically to establish a reasonable material removal rate model. The effects of the ultrasonic elliptical vibration on the interaction among the abrasive particles, polishing pad, and workpiece are investigated to explain why the MRR of UEV-CMP is higher than that of the conventional CMP. A mathematic model, which includes polishing variables such as morphology and material properties of polishing pad; abrasive size; and material properties of particles, frequency, and amplitude of the ultrasonic vibration as well as polishing process parameters, is set up to interpret the increase in MRR for UEV-CMP. The results from the MRR model show that the ultrasonic elliptical vibration can improve material removal by increasing both the chemical reaction efficiency of polishing solution and mechanical impact efficiency of the abrasive particles on the workpiece surface and also by increasing vibration amplitude in vertical direction as the horizontal vibration contributes less towards the increment of MRR. Experiments are conducted for model verification, which should be that the experimental results agree well with model predictions.

Similar content being viewed by others

References

Qin K, Moudgil B, Park CW (2004) A chemical mechanical polishing model incorporating both the chemical and mechanical effects. Thin Sold Films 446:277–286

Lee HS, Jeong HD (2009) Chemical and mechanical balance in polishing of electronic materials for defect-free surfaces. CIRP Ann Manuf Technol 58:485–490

Zhong ZW, Tian YB, Ang YJ, Wu H (2012) Optimization of the chemical mechanical polishing process for optical silicon substrates. Int J Adv Manuf Technol 60:1197–1206

Lei H, Tong KY, Wang ZY (2016) Preparation of Ce-doped colloidal SiO2 composite abrasives and their chemical mechanical polishing behavior on sapphire substrates. Mater Chem Phys 172:26–31

Zhang ZF, Yu L, Liu WL, Song ZT (2010) Surface modification of ceria nanoparticles and their chemical mechanical polishing behavior on glass substrate. Appl Surf Sci 256:3856–3861

Tian YB, Zhong ZW, Lai ST, Ang YJ (2013) Development of fixed abrasive chemical mechanical polishing process for glass disk substrates. Int J Adv Manuf Technol 68:993–1000

Gong H, Pan GS, Zhou Y, Shi XL, Zou CL, Zhang SM (2015) Investigation on the surface characterization of Ga-faced GaN after chemical-mechanical polishing. Appl Surf Sci 338:85–91

Zhou Y, Pan GS, Shi XL, Zhang SM, Gong H, Luo GH (2015) Effects of ultra-smooth surface atomic step morphology on chemical mechanical polishing (CMP) performances of sapphire and SiC wafers. Tribol Int 87:145–150

Hu XK, Song ZT, Pan ZC, Liu WL, Wu LC (2009) Planarization machining of sapphire wafers with boron carbide and colloidal silica as abrasives. Appl Surf Sci 255:8230–8234

Xu L, Zou CL, Shi XL, Pan GS, Luo GH, Zhou Y (2015) Fe-N x /C assisted chemical–mechanical polishing for improving the removal rate of sapphire. Appl Surf Sci 343:115–120

Pei ZJ, Ferreira PM (1998) Modeling of ductile-mode material removal in rotary ultrasonic machining. Int J Mach Tools Manuf 38:1399–1418

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. Precis Eng 32:153–172

Xu WH, Lu XC, Pan GS, Lei YZ, Luo JB (2010) Ultrasonic flexural vibration assisted chemical mechanical polishing for sapphire substrate. Appl Surf Sci 256:3936–3940

Xu WH, Lu XC, Pan GS, Lei YZ, Luo JB (2011) Effects of the ultrasonic flexural vibration on the interaction between the abrasive particles; pad and sapphire substrate during chemical mechanical polishing (CMP). Appl Surf Sci 257:2905–2911

Tsai MY, Yang WZ (2012) Combined ultrasonic vibration and chemical mechanical polishing of copper substrates. Int J Mach Tools Manuf 53:69–76

Li L, He Q, Zheng M, Liu Z (2015) Contribution of ultrasonic traveling wave to chemical-mechanical polishing. Ultrasonics 56:530–538

Zhao QL, Sun ZY, Guo B (2016) Material removal mechanism in ultrasonic vibration assisted polishing of micro cylindrical surface on SiC. Int J Mach Tools Manuf 103:28–39

Li YG, Wu YB, Zhou LB, Fujimoto M (2014) Vibration-assisted dry polishing of fused silica using a fixed-abrasive polisher. Int J Mach Tools Manuf 77:93–102

Yang WP, Xu JW, Wu YB (2008) Chemical-mechanical polishing principle and experimental system of ultrasonic elliptic vibration. J Nanjing Univ Aeronaut Astronaut 40(6):753–757 (in Chinese)

Liang ZQ, Wu YB, Wang XB, Zhao WX (2010) A new two-dimensional ultrasonic assisted grinding (2D-UAG) method and its fundamental performance in monocrystal silicon machining. Int J Mach Tools Manuf 50:728–736

Suzuki H, Hamada S, Okino T, Kondo M, Yamagata Y, Higuchi T (2010) Ultraprecision finishing of micro-aspheric surface by ultrasonic two-axis vibration assisted polishing. CIRP Ann-Manuf Technol 59:247–350

Yang WP, Wu YB, Yang HF (2011) Mechanism and experimental investigation on silicon wafer hybrid polishing by ultrasonic-elliptic-vibration chemical-mechanical. Adv Mater Res 314-316:829–836

Haynes WM (2014) CRC handbook of chemistry and physics. CRC press, London

Engel PA (1976) Impact wear of materials. Elsevier Scientific Pub. Co, New York

Bhushan B (2013) Introduction to tribology. John Wiley and Sons, London

Hu Q, Liu DF, Zou WB (2014) Material removal model and experimental analysis in the CMP of si-based fiber array. Adv Mater Res 941-944:2345–2365

Jiang JZ, Zhao YW, Wang YG, Luo JB (2008) A chemical mechanical polishing model based on the viscous flow of the amorphous layer. Wear 265:992–998

Luo JF, Dornfeld DA (2001) Material removal mechanism in chemical mechanical polishing: theory and modeling. IEEE Trans Semicond Manuf 14(2):112–133

Jeng YR, Huang PY (2005) A material removal rate model considering interfacial micro-contact wear behavior for chemical mechanical polishing. Trans ASME-J Tribol 127:190–197

Zhao YW, Chang L (2002) A micro-contact and wear model for chemical-mechanical polishing of silicon wafers. Wear 252:220–226

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, D., Yan, R. & Chen, T. Material removal model of ultrasonic elliptical vibration-assisted chemical mechanical polishing for hard and brittle materials. Int J Adv Manuf Technol 92, 81–99 (2017). https://doi.org/10.1007/s00170-017-0081-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0081-z