Abstract

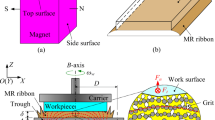

The geometric shape of magnets was modified to improve surface planarity and polishing efficiency in magnetorheological planarization. Two modified permanent magnetic yokes and a magnetic brick were used as excitation units of magnetic field. Stress analysis indicated that the polishing stress of the horizontal magnetic yoke was smaller than that of the brick magnet, but greater than that of the sloping yoke. The performances of MR planarizations, including removal rate, roughness, and planarity, of the three magnetic sources were also compared. The results showed that the sloping yoke produced the lowest surface finish of 0.6 nm in R a and the best planarity of 0.7 μm in PV, and the brick magnet provided the highest removal efficiency.

Similar content being viewed by others

References

Kordonski WI, Jacobs SD, Golini D, Fess E, Strafford D (1996) Vertical wheel magnetorheological finishing machine for flat, convex, and concave surfaces. Optical Fabrication and Testing 7:146–149

Saraswathammaa K, Jha S, Rao PV (2015) Experimental investigation into ball end magnetorheological finishing of silicon. Precis Eng 42:218–223

Seok J, Kim YJ, Jang KY, Min BK, Lee SJ (2007) A study on the fabrications of curved surfaces using magnetorheological fluid finishing. Int J Mach Tools Manuf 47:2077–2090

Jiao L, Wu Y, Wang X, Guo H, Liang Z (2013) Fundamental performance of magnetic compound fluid (MCF) wheel in ultra-fine surface finishing of optical glass. Int J Mach Tools Manuf 75:109–118

Jang K, Kim DY, Maeng S, Lee W, Han J, Seok J, Je TJ, Kang S, Min BK (2012) Deburring microparts using a magnetorheological fluid. International Journal of Machine Tools & Manufacture 53:170–175

Guo H, Wu Y, Lu D, Fujimoto M, Nomura M (2014) Effects of pressure and shear stress on material removal rate in ultra-fine polishing of optical glass with magnetic compound fluid slurry. J Mater Process Technol 214:2759–2769

Jain VK, Ranjan P, Suri VK, Komanduri R (2010) Chemo-mechanical magnetorheological finishing (CMMRF) of silicon for microelectronics applications. CIRP Ann Manuf Technol 59:323–328

Sidpara A, Jain VK (2011) Experimental investigations into forces during magnetorheological fluid based finishing process. Int J Mach Tools Manuf 51:358–362

Sidpara A, Jain VK (2012) Theoretical analysis of forces in magnetorheological fluid based finishing process. Int J Mech Sci 56:50–59

Sidpara A, Jain VK (2014) Rheological properties and their correlation with surface finish quality in MR fluid based finishing process. Mach Sci Technol 18:367–385

Das M, Jain VK, Ghoshdastidar PS (2012) Nanofinishing of flat workpieces using rotational-magnetorheological abrasive flow finishing process. Int J Adv Manuf Technol 62:405–420

Kordonski WI, Shorey AB, Sekeres A (2003) New magnetically assisted finishing method: material removal with magnetorheological fluid jet. Proc SPIE 5180:107–114

Wang T, Cheng HB, Dong ZC, Tam HY (2013) Removal character of vertical jet polishing with eccentric rotation motion using magnetorheological fluid. J Mater Process Technol 213:1532–1537

Wang YQ, Yin SH, Huang H, Chen FJ, Deng GJ (2015) Magnetorheological polishing using a permanent magnetic yoke with straight air gap for ultra-smooth surface planarization. Precis Eng 40:309–317

Wang YQ, Yin SH, Huang H (2016) Polishing characteristics and mechanism in magnetorheological planarization using a permanent magnetic yoke with translational movement. Precis Eng 43:93–104

Nagdeve L, Jain VK, Ramkumar J (2016) Experimental investigations into nano-finishing of freeform surfaces using negative replica of the knee joint. Procedia CIRP 42:793–798

Jain VK, Kalia S, Sidpara A (2012) Some aspects of fabrication of micro devices by electrochemical micromachining (ECMM) and its finishing by magnetorheological fluid. Int J Adv Manuf Technol 59:987–996

Krystek M (1996) A fast gauss filtering algorithm for roughness measurements. Precis Eng 19:198–200

Jayswal SC, Jain VK, Dixit PM (2005) Modeling and simulation of magnetic abrasive finishing process. Int J Adv Manuf Technol 26:477–490

Yi CJ, Peng XH, Zhao CW (2010) A magnetic-dipoles-based micro-macro constitutive model for MRFs subjected to shear deformation. Rheol Acta 49:815–825

Laun HM, Gabriel C, Schmidt G (2008) Primary and secondary normal stress differences of a magnetorheological fluid (MRF) up to magnetic flux density of 1 T. J Non-Newtonian Fluid Mech 148:47–56

Guo CY, Gong XL, Xuan SH, Qin LJ, Yan QF (2013) Compression behaviors of magnetorheological fluids under nonuniform magnetic field. Rheol Acta 52(2):165–176

Gere JM, Goodno BJ (2009) Mechanics and materials 7th edition. Cengage Learning, USA

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Yin, S. & Huang, H. A comparative study on magnetorheological planarization using modified magnetic yokes and brick magnet. Int J Adv Manuf Technol 91, 2831–2841 (2017). https://doi.org/10.1007/s00170-016-9908-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9908-2