Abstract

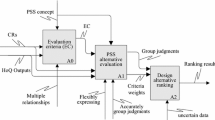

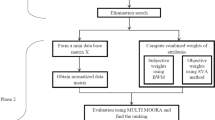

Additive manufacturing (AM) or 3D printing, as an enabling technology for mass customization or personalization, has been developed rapidly in recent years. Various design tools, materials, machines and service bureaus can be found in the market. Clearly, the choices are abundant, but users can be easily confused as to which AM process they should use. This paper first reviews the existing multi-attribute decision-making methods for AM process selection and assesses their suitability with regard to two aspects, preference rating flexibility and performance evaluation objectivity. We propose that an approach that is capable of handling incomplete attribute information and objective assessment within inherent data has advantages over other approaches. Based on this proposition, this paper proposes a weighted preference graph method for personalized preference evaluation and a rough set based fuzzy axiomatic design approach for performance evaluation and the selection of appropriate AM processes. An example based on the previous research work of AM machine selection is given to validate its robustness for the priori articulation of AM process selection decision support.

Similar content being viewed by others

Reference

ISO/PRF17296-1 (2015). Additive manufacturing—General principles—Part 1: Terminology. International Organization for Standardization, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva, Switzerland

Gibson I, Rosen DW, Stucker B (2010) Design for additive manufacturing. In: Additive Manufacturing Technologies. Springer. ISBN: 978-1-4939-2112-6 (Print) 978-1-4939-2113-3 (Online), pp 299–332

Lan H, Ding Y, Hong J (2005) Decision support system for rapid prototyping process selection through integration of fuzzy synthetic evaluation and an expert system. Int J Prod Res 43(1):169–194

Waterman NA, Dickens P (1994) Rapid product development in the USA, Europe and Japan. World Class Design to Manufacture 1(3):27–36

F42 A (2012) ASTM F2792-12a, standard terminology for additive manufacturing technologies. ASTM International, West Conshohocken, PA

Senvol LLC (2015) senvol database. Available: senvolcom

Byun HS, Lee KH (2005) A decision support system for the selection of a rapid prototyping process using the modified TOPSIS method. Int J Adv Manuf Technol 26(11–12):1338–1347. doi:10.1007/s00170-004-2099-2

Kerbrat O, Mognol P, Hascoët J-Y (2010) Manufacturability analysis to combine additive and subtractive processes. Rapid Prototyp J 16(1):63–72

Kerbrat O, Mognol P, Hascoet J-Y (2010) Manufacturing complexity evaluation at the design stage for both machining and layered manufacturing. CIRP J Manuf Sci Technol 2(3):208–215

Mahapatra SS, Panda BN (2013) Benchmarking of rapid prototyping systems using grey relational analysis. International Journal of Services and Operations Management 16(4):460–477

Zhai L-Y, Khoo L-P, Zhong Z-W (2008) A rough set enhanced fuzzy approach to quality function deployment. Int J Adv Manuf Technol 37(5–6):613–624. doi:10.1007/s00170-007-0989-9

Zhai LY, Khoo LP, Zhong ZW (2009) A rough set based QFD approach to the management of imprecise design information in product development. Adv Eng Inform 23(2):222–228. doi:10.1016/j.aei.2008.10.010

Jin Y (2003) Advanced fuzzy systems design and applications, vol 112. Springer. ISBN 978-3-7908-1771-3

Pawlak Z (1982) Rough sets. International Journal of Computer & Information Sciences 11(5):341–356

Khoo L, Tor S, Zhai L (1999) A rough-set-based approach for classification and rule induction. Int J Adv Manuf Technol 15(6):438–444

Pawlak Z (1991) Rough sets: Theoretical aspects of reasoning about data, vol 9. Springer. ISBN 978-94-011-3534-4

Mahesh M, Fuh JY, Wong Y, Loh HT (2005) Benchmarking for decision making in rapid prototyping systems. In: Automation Science and Engineering. IEEE International Conference on, 2005. IEEE, pp 19–24

Zhang Y, Xu Y, Bernard A (2014) A new decision support method for the selection of RP process: knowledge value measuring. Int J Comput Integr Manuf 27(8):747–758

Wang P, Meng P, Zhai J-Y, Zhu Z-Q (2013) A hybrid method using experiment design and grey relational analysis for multiple criteria decision making problems. Knowl-Based Syst 53:100–107

Vahdani B, Mousavi SM, Tavakkoli-Moghaddam R (2011) Group decision making based on novel fuzzy modified TOPSIS method. Appl Math Model 35(9):4257–4269

Chakraborty S (2011) Applications of the MOORA method for decision making in manufacturing environment. Int J Adv Manuf Technol 54(9–12):1155–1166

İç YT (2012) An experimental design approach using TOPSIS method for the selection of computer-integrated manufacturing technologies. Robot Comput Integr Manuf 28(2):245–256

Khrais S, Al-Hawari T, Al-Araidah O (2011) A fuzzy logic application for selecting layered manufacturing techniques. Expert Syst Appl 38(8):10286–10291

Chuk RN, Thomson VJ (1998) A comparison of rapid prototyping techniques used for wind tunnel model fabrication. Rapid Prototyp J 4(4):185–196

Jones K, Campbell R (1997) Rapid prototyping decision support system. In: Proceedings Fast Freeform Fabrication Symposium, University of Texas at Austin, Austin. August 1997, pp551–558

Roberson D, Espalin D, Wicker R (2013) 3D printer selection: a decision-making evaluation and ranking model. Virtual and Physical Prototyping 8(3):201–212

Ghazy MM (2012) Development of an additive manufacturing decision support system (AMDSS). Newcastle University. NE1 7RU, United Kingdom. PhD thesis

Munguia J, Bernard A, Erdal M (2011) Proposal and evaluation of a KBE-RM selection system. Rapid Prototyp J 17(4):236–246

Zhang Y, Bernard A (2014) An integrated decision-making model for multi-attributes decision-making (MADM) problems in additive manufacturing process planning. Rapid Prototyp J 20(5):377–389

Lan H, Ding Y, Hong J (2005) Decision support system for rapid prototyping process selection through integration of fuzzy synthetic evaluation and an expert system. Int J Prod Res 43(1):169–194

Armillotta A (2008) Selection of layered manufacturing techniques by an adaptive AHP decision model. Robot Comput Integr Manuf 24(3):450–461. doi:10.1016/j.rcim.2007.06.001

Lokesh K, Jain P (2010) Selection of rapid prototyping technology. Advances in Production Engineering & Management 5(2):75–84

Rao RV, Padmanabhan K (2007) Rapid prototyping process selection using graph theory and matrix approach. J Mater Process Technol 194(1):81–88

Wilson JO, Rosen D (2005) Selection for rapid manufacturing under epistemic uncertainty. In: ASME 2005 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. American Society of Mechanical Engineers, pp 451–460

Liao S, Wu M-J, Huang C-Y, Kao Y-S, Lee T-H (2014) Evaluating and Enhancing Three-Dimensional Printing Service Providers for Rapid Prototyping Using the DEMATEL Based Network Process and VIKOR. Mathematical Problems in Engineering 2014

Venkata Rao R, Patel BK (2010) Decision making in the manufacturing environment using an improved PROMETHEE method. Int J Prod Res 48(16):4665–4682

Fernandez MG, Seepersad CC, Rosen DW, Allen JK, Mistree F (2005) Decision support in concurrent engineering–the utility-based selection decision support problem. Concurr Eng 13(1):13–27

Lai X, Xie M, Tan K-C, Yang B (2008) Ranking of customer requirements in a competitive environment. Comput Ind Eng 54(2):202–214

Chuang P-T (2001) Combining the analytic hierarchy process and quality function deployment for a location decision from a requirement perspective. Int J Adv Manuf Technol 18(11):842–849

Chan L, Kao H, Wu M (1999) Rating the importance of customer needs in quality function deployment by fuzzy and entropy methods. Int J Prod Res 37(11):2499–2518

Nahm YE, Ishikawa H, Inoue M (2013) New rating methods to prioritize customer requirements in QFD with incomplete customer preferences. Int J Adv Manuf Technol 65(9–12):1587–1604. doi:10.1007/s00170-012-4282-1

Suh NP (1990) The principles of design, vol 990. Oxford University Press, New York

Suh NP (2001) Axiomatic Design: Advances and Applications (The Oxford Series on Advanced Manufacturing).

Kulak O, Kahraman C (2005) Multi-attribute comparison of advanced manufacturing systems using fuzzy vs. crisp axiomatic design approach. Int J Prod Econ 95(3):415–424. doi:10.1016/j.ijpe.2004.02.009

Kulak O, Kahraman C (2005) Fuzzy multi-attribute selection among transportation companies using axiomatic design and analytic hierarchy process. Inf Sci 170(2–4):191–210. doi:10.1016/j.ins.2004.02.021

Zheng P, Xie SQ A (2015) Rough set based fuzzy axiomatic design approach in evaluating customer-centric design alternatives. In: Industrial Engineering and Engineering Management (IEEM), 2015 I.E. International Conference on, 6–9 Dec. 2015. pp 544–548. doi: 10.1109/IEEM.2015.7385706

Celik M, Kahraman C, Cebi S, Er ID (2009) Fuzzy axiomatic design-based performance evaluation model for docking facilities in shipbuilding industry: the case of Turkish shipyards. Expert Syst Appl 36(1):599–615. doi:10.1016/j.eswa.2007.09.055

Chen SW, Liu J, Wang H, Augusto JC (2013) Ordering based decision making—a survey. Information Fusion 14(4):521–531. doi:10.1016/j.inffus.2012.10.005

Franceschini F, Maisano D, Mastrogiacomo L (2015) Customer requirement prioritization on QFD: a new proposal based on the generalized Yager's algorithm. Res Eng Des 26(2):171–187. doi:10.1007/s00163-015-0191-2

Nahm Y-E, Ishikawa H (2005) Representing and aggregating engineering quantities with preference structure for set-based concurrent engineering. Concurr Eng 13(2):123–133

Simos J (1990) Évaluer l’impact sur l’environnement: une approche originale par l’analyse multicritère et la négociation. Presses polytechniques et universitaires romandes. Lausanne Switzerland 1990

Lial ML, Greenwell R, Ritchey N (2002) Finite mathematics and calculus. Pearson Education, Inc, New York

Figueira J, Roy B (2002) Determining the weights of criteria in the ELECTRE type methods with a revised Simos' procedure. Eur J Oper Res 139(2):317–326

Shanian A, Milani A, Carson C, Abeyaratne R (2008) A new application of ELECTRE III and revised Simos’ procedure for group material selection under weighting uncertainty. Knowl-Based Syst 21(7):709–720

Marzouk M, Nouh A, El-Said M (2014) Developing green bridge rating system using Simos’ procedure. HBRC Journal 10(2):176–182

Moylan S, Slotwinski J, Cooke A, Jurrens K, Donmez MA (2012) Proposal for a standardized test artifact for additive manufacturing machines and processes. In: Proceedings of the 2012 Annual International Solid Freeform Fabrication Symposium, pp 6–8

Rao RV, Patel BK (2010) A subjective and objective integrated multiple attribute decision making method for material selection. Mater Des 31(10):4738–4747. doi:10.1016/j.matdes.2010.05.014

Byun H-S, Lee KH (2006) Determination of the optimal build direction for different rapid prototyping processes using multi-criterion decision making. Robot Comput Integr Manuf 22(1):69–80

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, P., Wang, Y., Xu, X. et al. A weighted rough set based fuzzy axiomatic design approach for the selection of AM processes. Int J Adv Manuf Technol 91, 1977–1990 (2017). https://doi.org/10.1007/s00170-016-9890-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9890-8