Abstract

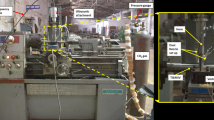

A model of friction stir spot welding (FSSW) between aluminum alloy 6061-T6 and TRIP 780 steel is developed in this work based on the Coupled Eulerian-Lagrangian (CEL) method, which considers the material flow at the dissimilar material interface and also the interaction between the welding tool and workpiece. The cross-sectional view from the numerical result agrees well with the experimental observations. The material distribution at different plunge depths calculated by the model illustrates the formation of the hook during the welding process. The force and thermal history generated by the numerical work also correspond well with the experimental data. A force history generated through a tool with a smaller shoulder diameter is studied to further validate the model. The developed model can be useful for better understanding the effect of the welding tool on FSSW and optimization of the tool geometry.

Similar content being viewed by others

References

Nandan R et al (2007) Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater 55(3):883–895

Cho H-H et al (2013) Three-dimensional numerical and experimental investigation on friction stir welding processes of ferritic stainless steel. Acta Mater 61(7):2649–2661

Schmidt H, Hattel J (2005) A local model for the thermomechanical conditions in friction stir welding. Model Simul Mater Sci Eng 13(1):77–93

Kim D et al (2010) Numerical simulation of friction stir butt welding process for AA5083-H18 sheets. European Journal of Mechanics - A/Solids 29(2):204–215

Jamshidi Aval H, Serajzadeh S, Kokabi AH (2011) Experimental and theoretical evaluations of thermal histories and residual stresses in dissimilar friction stir welding of AA5086-AA6061. Int J Adv Manuf Technol 61(1–4):149–160

Mandal S, Rice J, Elmustafa AA (2008) Experimental and numerical investigation of the plunge stage in friction stir welding. J Mater Process Technol 203(1–3):411–419

Awang M et al (2005) Thermo-mechanical modeling of friction stir spot welding (FSSW) process: use of an explicit adaptive meshing scheme. No. 2005-01-1251. SAE Technical Paper

Liu X, Lan S, Ni J (2015) Thermal mechanical modeling of the plunge stage during friction-stir welding of dissimilar Al 6061 to TRIP 780 steel. J Manuf Sci Eng 137(5):051017–051017

Benson D (1995) A multi-material Eulerian formulation for the efficient solution of impact and penetration problems. Comput Mech 15(6):558–571

Benson DJ (1997) A mixture theory for contact in multi-material Eulerian formulations. Comput Methods Appl Mech Eng 140(1):59–86

Benson DJ, Okazawa S (2004) Contact in a multi-material Eulerian finite element formulation. Comput Methods Appl Mech Eng 193(39):4277–4298

Brown KH, Burns SP, Christon MA (2002) Coupled Eulerian-Lagrangian methods for earth penetrating weapon applications. SAND2002-1014. Albuquerque, NM, US: Sandia National Laboratories

Aquelet N, Souli M, Olovsson L (2006) Euler–Lagrange coupling with damping effects: application to slamming problems. Comput Methods Appl Mech Eng 195(1):110–132

McGlaun JM, Thompson S, Elrick M (1990) CTH: a three-dimensional shock wave physics code. International Journal of Impact Engineering 10(1–4):351–360

Awang M (2007) Simulation of friction stir spot welding (FSSW) process: study of friction phenomena. PhD Dissertation, West Virginia University

Zhang Z, Chen J (2008) The simulation of material behaviors in friction stir welding process by using rate-dependent constitutive model. J Mater Sci 43(1):222–232

Sanjeev N, Malik V, Hebbar HS (2014) Effect of coefficient of friction in finite element modeling of friction stir welding and its importance in manufacturing process modeling applications. International Journal of Applied Science and Engineering Research 3(4):755–762

Gueyffier D et al (1999) Volume-of-fluid interface tracking with smoothed surface stress methods for three-dimensional flows. J Comput Phys 152(2):423–456

Ulysse P (2002) Three-dimensional modeling of the friction stir-welding process. Int J Mach Tools Manuf 42(14):1549–1557

Al-Badour F et al (2013) Coupled Eulerian-Lagrangian finite element modeling of friction stir welding processes. J Mater Process Technol 213(8):1433–1439

Hossfeld M, Roos E A new approach to modelling friction stir welding using the CEL method. Advanced Manufacturing Engineering and Technologies (NEWTECH 2013), Stockholm, Sweden 27–30, October 2013, p. 179

Al-Badour F et al (2014) Thermo-mechanical finite element model of friction stir welding of dissimilar alloys. Int J Adv Manuf Technol 72(5–8):607–617

Figner MSG et al (2009) Friction stir spot welds between aluminium and steel automotive sheets: influence of welding parameters on mechanical properties and microstructure. Welding in the World 53(1–2):R13–R23

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, K., Liu, X. & Ni, J. Thermal-mechanical modeling on friction stir spot welding of dissimilar materials based on Coupled Eulerian-Lagrangian approach. Int J Adv Manuf Technol 91, 1697–1707 (2017). https://doi.org/10.1007/s00170-016-9884-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9884-6