Abstract

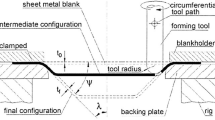

Controlling the strain rate during superplastic forming is the main reason to implement time-variable gas pressure profiles. In the present research, a new approach is introduced for controlling the strain rate during free bulge forming. The approach was examined by performing the superplastic forming operation with the Al-Mg5.6 aluminum alloy as a valuable material in transportation industries. Free bulge forming operations were performed at 500 °C and a strain rate range of 8 × 10−5–5.7 × 10−4 s−1. The changes of the strain rate at the apex of the workpiece were numerically monitored during the deformation, and a new strategy to smooth these changes was implemented. New time-dependent pressure profiles were defined, and their influences on the forming time and uniformity of the deformed part were examined. Finally, the stepwise rising pressure function followed by a constant pressure at which the time of increasing (T r) was between 20 and 40% of the total time needed for merely applying that constant pressure was shown to provide the best results. This type of pressure profile can also improve the uniformity of thickness and save the process time, compared with forming at a constant low pressure. Moreover, this stepwise pressure function is easy to be practically employed in various industrial applications.

Similar content being viewed by others

References

Taub AI, Krajewski PE, Luo AA, Ownes JN (2007) The evolution of technology for materials processing over the last 50 years: the automotive example. JOM 59(2):48–57

Taleff EM, Hector LG, Bradley JR, Verma R, Krajewski PE (2009) The effect of stress state on high-temperature deformation of fine-grained aluminum–magnesium alloy AA5083 sheet. Acta Mater 57:2812–2822

Khaleel MA, Johnson KI, Hamilton CH, Smith MT (1998) Deformation modeling of superplastic AA 5083. Int J Plasticity 14:1133–1154

Romhanji E, Popovic M, Radmilovic V (1999) Room temperature deformation behavior of AlMg6.5 alloy sheet. Z Metallkd 90(4):305–310

Franchitti S, Giuliano G, Palumbo G, Sorgente D, Tricarico L (2008) On the optimization of superplastic free forming test of an AZ31 magnesium alloy sheet, Int. J Mater Form 1:1067–1070

Barnes AJ (2007) Superplastic forming 40 years and still growing. J Mater Eng Perform 4:440–454

Dutta A, Mukherjee M (1992) Superplastic forming: an analytical approach. Mater Sci Eng A 157(1):9–13

Banabic D, Balan T, Comsa DS (2001) Closed form solution for bulging through elliptical dies. J. Mater. Process. Tech. 115:83–86

Abu-Farha F (2007) Integrated approach to the superplastic forming of magnesium alloy. Doctoral thesis. University of Kentucky

Abu-Farha F, Verma R, Hector LG Jr (2012) High temperature composite forming limit diagrams of four magnesium AZ31B sheets obtained by pneumatic stretching. J Mater Process Tech 212:1414–1429

Hambli R, Potiron A, Guerin F, Dumon B (2001) Numerical pressure prediction algorithm for superplastic forming processes using 2D and 3D models. J Mater Process Tech 112:83–90

Jarrar FS, Hector LG, Khraisheh MK, Bower AF (2010) New approach to gas pressure profile prediction for high temperature AA5083 sheet forming. J Mater Process Tech 210:825–834

Liu J, Tan MJ, Lim CVS (2013) Process optimization and microstructural development during superplastic-like forming of AA5083. Int J Adv Manuf Technol 69:2415–2422

Guiliano G (2008) Constitutive equation for superplastic Ti-6Al-4V alloy. Mater Des 29:1330–1333

Taleef EM, Hector LG, Verma R, Krajewski PE, Chang JK (2010) Material models for simulation of superplastic Mg alloy sheet forming. J Mater Eng Perform 19:488–494

Guan Z, Ren M, Zhao P, Ma P, Wang Q (2014) Constitutive equations with varying parameters for superplastic flow behavior of Al-Zn-Mg-Zr alloy. Mater Des 54:906–913

Guan Z, Ren M, Jia H, Zhao P, Ma P (2014) Constitutive equation with varying parameters for superplastic flow behavior. J Mater Eng Perform 23:791–798

Nazzal MA, Khraisheh MK, Darras BM (2004) Finite element modeling and optimization of superplastic forming using variable strain rate approach. J Mater Eng Perform 13:691–699

Yang CF, Chiu LH, Lee SC (1996) Superplastic forming of 7475 al alloy by variable pressure blowing. Scripta Mater 34(10):1555–1560

Sun P, Wu H, Tsai H, Huang C, Tzou M (2010) Effect of pressurization profile on the deformation characteristic of fine-grained AZ31B Mg alloy sheet during gas blow forming. J. Mater. Process. Tech. 210:1673–1679

Sorgente D, Palumbo G, Scintilla LD, Tricarico L (2015) Gas forming of an AZ31 magnesium alloy at elevated strain rates. Int J Adv Manuf Technol 83(5):861–872

Chung SW, Higashi K, Kim WJ (2004) Superplastic gas pressure forming of fine grained AZ61 magnesium alloy sheet. Mater Sci Eng A 372:15–20

Jarrar F (2014) Designing gas pressure profile for AA 5083 superplastic forming. Procedia Eng 81:1084–1089

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fereshteh-Saniee, F., Fakhar, N., Asgari, M. et al. A new experimental-numerical approach for studying the effects of gas pressure profile on superplastic forming characteristics of Al-Mg5.6 alloy. Int J Adv Manuf Technol 91, 1771–1780 (2017). https://doi.org/10.1007/s00170-016-9871-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9871-y