Abstract

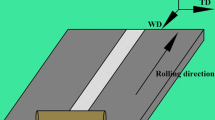

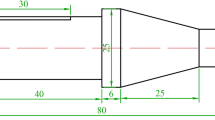

Mg-Al-Sn magnesium alloys have bright future in application because of good properties without rare earth elements. To study the effects of rotation rate on microstructures and mechanical properties of Mg-5Al-1Sn alloy after friction stir welding (FSW), extruded plates were butt welded by FSW with various rotation rates at constant other parameters. The results showed that after FSW, Mg17Al12 phase with poor thermal stability was dissolved, while Mg2Sn phase remained due to high dissolution point and good thermal stability. The hole-type defects were observed at 600 rpm, and the weld joint was with no defects at 800~1100 rpm. The weld joint at 800 rpm gave a maximum ultimate tensile strength (UTS), which was 91% of the base material (BM). After FSW, both UTS and elongation of weld joints decreased compared with the BM, caused by the soften region between nugget zone (NZ) and thermo-mechanically affected zone (TMAZ), the dissolution of Mg17Al12 phases, the residual stress and dislocation content in the TMAZ, and the textural variation. With increasing rotation rate from 600 to 1100 rpm, the UTS of weld joints first increased and then decreased, while the elongation kept mostly unchangeable due to the common action of multifactors.

Similar content being viewed by others

References

Liu LM, Dong CF (2006) Gas tungsten-arc filler welding of AZ31 magnesium alloy. Mater Lett 60:2194–2197. doi:10.1016/j.matlet.2005.12.120

Mohammadzadeh Jamalian M, Farahani M, Besharati Givil MK, Aghaei Vafaei M (2016) Study on the effects of friction stir welding process parameters on the microstructure and mechanical properties of 5086-H34 aluminum welded joints. Int J Adv Manuf Technol 83:611–621. doi:10.1007/s00170-015-7581-5

He J, Ling ZM, Li HM (2016) Effect of tool rotational speed on residual stress, microstructure, and tensile properties of friction stir welded 6061-T6 aluminum alloy thick plate. Int J Adv Manuf Technol 84:1953–1961. doi:10.1007/s00170-015-7859-7

Asadi P, Givi MKB, Akbari M (2016) Simulation of dynamic recrystallization process during friction stir welding of AZ91 magnesium alloy. Int J Adv Manuf Technol 83:301–311. doi:10.1007/s00170-015-7595-z

Chowdhury SH, Chen DL, Bhole SD, Cao X, Wanjara P (2013) Friction stir welded AZ31 magnesium alloy: microstructure, texture, and tensile properties. Metall Mater Trans A 44A:323–336. doi:10.1007/s11661-012-1382-3

Sahu PK, Pal S (2015) Multi-response optimization of process parameters in friction stir welded AM20 magnesium alloy by Taguchi grey relational analysis. J Magnes Alloy 3:36–46. doi:10.1016/j.jma.2014.12.002

Ni DR, Chen DL, Wang D, Xiao BL, Ma ZY (2014) Tensile properties and strain-hardening behaviour of friction stir welded SiCp/AA2009 composite joints. Mater Sci Eng A 608:1–10. doi:10.1016/j.msea.2014.04.060

Wang WD, Deng DA, Mao ZT, Tong YG, Ran Y (2016) Influence of tool rotation rates on temperature profiles and mechanical properties of friction stir welded AZ31 magnesium alloy. Int J Adv Manuf Technol online. doi:10.1007/s00170-016-8918-4

Commin L, Dumont M, Masse JE, Barrallier L (2009) Friction stir welding of AZ31 magnesium alloy rolled sheets: influence of processing parameters. Acta Mater 57:326–334. doi:10.1016/j.actamat.2008.09.011

Cao X, Jahazi M (2009) Effect of welding speed on the quality of friction stir welded butt joints of a magnesium alloy. Mater Des 30:2033–2042. doi:10.1016/j.matdes.2008.08.040

Cao X, Jahazi M (2011) Effect of tool rotational speed and probe length on lap joint quality of a friction stir welded magnesium alloy. Mater Design 32:1–11. doi:10.1016/j.matdes.2010.06.048

Dobriyal RP, Dhindawa BK, Muthukumaranb S, Mukherjeeb SK (2008) Microstructure and properties of friction stir butt-welded AE42 magnesium alloy. Mater Sci Eng A 477:243–249. doi:10.1016/j.msea.2007.06.028

Rao HM, Rodriguez RI, Jordon JB, Barkey ME, Guo YB, Badarinarayan H, Yuan W (2014) Friction stir spot welding of rare-earth containing ZEK100 magnesium alloy sheets. Mater Design 56:750–754. doi:10.1016/j.matdes.2013.12.034

Carlone P, Palazzo GS (2015) Characterization of TIG and FSW weldings in cast ZE41A magnesium alloy. J Mater Process Tech 215:87–94. doi:10.1016/j.jmatprotec.2014.07.026

Hono K, Mendis CL, Sasaki TT, Oh-ishi K (2010) Towards the development of heat-treatable high-strength wrought Mg alloys. Scripta Mater 63:710–715. doi:10.1016/j.scriptamat.2010.01.038

Pan FS, Xu AL, Deng DA, Ye JH, Jiang XQ, Tang AT, Yang R (2016) Effects of friction stir welding on microstructure and mechanical properties of magnesium alloy Mg-5Al-3Sn. Mater Des 110:266–274. doi:10.1016/j.matdes.2016.07.146

Luo AA, Fu PH, Peng LM, Kang XY, Li ZZ, Zhu TY (2012) Solidification microstructure and mechanical properties of cast magnesium-aluminum-tin alloys. Metall Mater Trans A 43:360–368. doi:10.1007/s11661-011-0820-y

Elsayed FR, Sasaki TT, Mendis CL, Ohkubo T, Hono K (2013) Compositional optimization of Mg-Sn-Al alloys for higher age hardening response. Mater Sci Eng A 566:22–29. doi:10.1016/j.msea.2012.12.041

Kabir ASH, Sanjari M, Su J, Jung I, Yue S (2014) Effect of strain-induced precipitation on dynamic recrystallization in Mg-Al-Sn alloys. Mater Sci Eng A 616:252–259. doi:10.1016/j.msea.2014.08.032

Xu AL, Pan FS, Jiang XQ, Li C, Ran Y (2015) Microstructure and properties of friction stir welded Mg-1Al-xSn-0.3Mn magnesium alloys. Mater Sci Forum 816:349–355. doi:10.4028/www.scientific.net/MSF.816.349

Zhou L, Nakata K, Liao J, Tsumura T (2012) Microstructural characteristics and mechanical properties of non-combustive Mg-9Al-Zn-Ca magnesium alloy friction stir welded joints. Mater Design 42:505–512. doi:10.1016/j.matdes.2012.06.005

Lohwasser D, Chen Z (2010) Friction stir welding from basics to applications. Woodhead Publishing Limited and CRC Press LLC, Boca Raton, pp. 15–17

Park SHC, Sato YS, Kokawa H (2003) Effect of micro-texture on fracture location in friction stir weld of Mg alloy AZ61 during tensile test. Scripta Mater 49:161–166. doi:10.1016/s1359-6462(03)00210-0

Afrin N, Chen DL, Cao X, Jahazi M (2008) Microstructure and tensile properties of friction stir welded AZ31B magnesium alloy. Mater Sci Eng A 472:179–186. doi:10.1016/j.msea.2007.03.018

Yang J, Xiao BL, Wang D, Ma ZY (2010) Effects of heat input on tensile properties and fracture behavior of friction stir welded Mg–3Al–1Zn alloy. Mater Sci Eng A 527:708–714. doi:10.1016/j.msea.2009.09.044

Albakri AN, Mansoor B, Nassar H, Khraisheh MK (2013) Thermo-mechanical and metallurgical aspects in friction stir processing of AZ31 Mg alloy—a numerical and experimental investigation. J Mater Process Tech 213:279–290. doi:10.1016/j.jmatprotec.2012.09.015

Darras BM, Khraisheh MK, Abu-Farha FK, Omar MA (2007) Friction stir processing of commercial AZ31 magnesium alloy. J Mater Process Tech 191:77–81. doi:10.1016/j.jmatprotec.2007.03.045

Mironov S, Onuma T, Sato YS, Kokawa H (2015) Microstructure evolution during friction-stir welding of AZ31 magnesium alloy. Acta Mater 100:301–312. doi:10.1016/j.actamat.2015.08.066

Ji SD, Shi QY, Zhang LG, Zou AL, Gao SS, Zan LV (2012) Numerical simulation of material flow behavior of friction stir welding influenced by rotational tool geometry. Comput Mater Sci 63:218–226. doi:10.1016/j.commatsci.2012.06.001

Chai F, Zhang DT, Li YY, Zhang W (2015) Microstructure evolution and mechanical properties of a submerged friction-stir-processed AZ91 magnesium alloy. J Mater Sci 50:3212–3225. doi:10.1007/s10853-015-8887-2

Motallebnejad P, Saeid T, Heidarzadeh A, Darzi KH, Ashjari M (2014) Effect of tool pin profile on microstructure and mechanical properties of friction stir welded AZ31B magnesium alloy. Mater Des 59:221–226. doi:10.1016/j.matdes.2014.02.068

Dong P, Li HM, Sun DQ, Gong WB, Liu J (2013) Effects of welding speed on the microstructure and hardness in friction stir welding joints of 6005A-T6 aluminum alloy. Mater Design 45:524–531. doi:10.1016/j.matdes.2012.09.040

Yang J, Wang D, Xiao BL, Ni DR, Ma ZY (2013) Effects of rotation rates on microstructure, mechanical properties, and fracture behavior of (FSW) AZ31 magnesium alloy. Metall Mater Trans A 44A:517–530. doi:10.1007/s11661-012-1373-4

Pareek M, Polar A, Rumiche F (2006) Proceedings of the seventh international conference on trends in welding research. ASM International GA, United State, May 16-20:421–426

Woo W, Choo H, Brown DW, Liaw PK, Feng Z (2006) Texture variation and its influence on the tensile behavior of a friction-stir processed magnesium alloy. Scripta Mater 54:1859–1864. doi:10.1016/j.scriptamat.2006.02.019

Ren SR, Ma ZY, Chen LQ (2007) Effect of welding parameters on tensile properties and fracture behavior of friction stir welded Al–Mg–Si alloy. Scripta Mater 56:69–72. doi:10.1016/j.scriptamat.2006.08.054

Liu HJ, Fujii H, Maeda M, Nogi K (2003) Mechanical properties of friction stir welded joints of 1050-H24 aluminium alloy. Sci Technol Weld Join 8:450–454

Moshwan R, Yusof F, Hassan MA, Rahmat SM (2015) Effect of tool rotational speed on force generation, microstructure and mechanical properties of friction stir welded Al-Mg-Cr-Mn (AA 5052-O) alloy. Mater Design 66:118–128. doi:10.1016/j.matdes.2014.10.043

Commin L, Dumontb M, Rotinata R, Pierrona F, Massec JE, Barrallierc L (2012) Influence of the microstructural changes and induced residual stresses on tensile properties of wrought magnesium alloy friction stir welds. Mater Sci Eng A 551:288–292. doi:10.1016/j.msea.2012.05.021

Commin L, Dumont M, Masse JE, Barrallier L (2009) Friction stir welding of AZ31 magnesium alloy rolled sheets: influence of processing parameters. Acta Mater 57:326–334. doi:10.1016/j.actamat.2008.09.011

Park SHC, Sato YS, Kokawa H (2003) Basal plane texture and flow pattern in friction stir weld of a magnesium alloy. Metall Mater Trans A 34A:987–994. doi:10.1007/s11661-003-0228-4

Emam SA, Domiaty AE (2009) A refined energy-based model for friction-stir welding. Proceedings of world Academy of Science. Eng Technol 53:1016–1022

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Pan, F., Xu, A., Ye, J. et al. Effects of rotation rate on microstructure and mechanical properties of friction stir-welded Mg-5Al-1Sn magnesium alloy. Int J Adv Manuf Technol 91, 389–397 (2017). https://doi.org/10.1007/s00170-016-9752-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9752-4