Abstract

Serrated contact wheels are widely used in robotic surface finishing process. This paper studies the pressure distribution at the interface between a serrated contact wheel and a workpiece, which is a key factor influencing the material removal process. Finite element models are developed to simulate different contact scenarios of the serrated wheels during the robotic finishing process. The effects of neoprene rubber materials, which introduce compliant property in serrated contact wheels are investigated in detail. The experimental work has been conducted to verify the pressure distributions obtained from the finite element analysis and to observe the behavior of the pressure distribution for two types of contact wheels of the same diameter, namely serrated type and flat type. This effort provides insights into industrial applications and the usefulness of finite element models in terms of compliant contact wheels for robotic surface finishing processes.

Similar content being viewed by others

References

Arunachalam APS, Idapalapati S, Subbiah S (2015) Multi-criteria decision making techniques for compliant polishing tool selection. Int J Adv Manuf Technol 79(1–4):519–530

Jackson MJ, Davim JP (2010) Machining with abrasives , USSpringer

Ren X, Kuhlenkötter B (2008) Real-time simulation and visualization of robotic belt grinding processes. Int J Adv Manuf Technol 35(11–12):1090–1099

Wang Y, Huang Y, Chen Y, Yang Z (2015) Model of an abrasive belt grinding surface removal contour and its application. Int J Adv Manuf Technol :1–10

Wu S (2012) Robotic Conformance Grinding Modeling, Control and Optimization. University of Connecticut,

Vlassak JJ (2004) A model for chemical–mechanical polishing of a material surface based on contact mechanics. Journal of the Mechanics and Physics of Solids 52(4):847–873. doi:10.1016/j.jmps.2003.07.007

Umer M, Saptaji K, Subbiah S Study of Pressure Distribution in Compliant Coated Abrasive Tools for Robotic Polishing. In: Proceedings of the ASME International Manufacturing Science and Engineering, 2012. ASME,

Ren X, Cabaravdic M, Zhang X, Kuhlenkötter B (2007) A local process model for simulation of robotic belt grinding. Int J Mach Tools Manuf 47(6):962–970

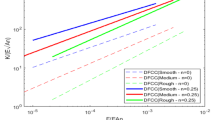

Sun Y, Vu TT, SH Y (2015) Study of pressure distribution in compliant contact wheels for robotic surface finishing. In, International Conference on Control, Mechatronics and Automation

Toupin RA (1965) Saint-Venant’s principle. Arch Ration Mech Anal 18(2):83–96

Martins P, Natal Jorge R, Ferreira A (2006) A comparative study of several material models for prediction of hyperelastic properties: application to silicone-rubber and soft tissues. Strain 42(3):135–147

Marinescu ID, Rowe WB, Dimitrov B, Inaski I (2004) Tribology of abrasive machining processes. Elsevier,

Johnson KL (1987) Normal contact of elastic solids - Hertz theory In: Contact Mechanics. Cambridge University Press, pp 84–106

Liu Y, Hua L (2010) Fabrication of metallic bipolar plate for proton exchange membrane fuel cells by rubber pad forming. J Power Sources 195(11):3529–3535

Sala G (2001) A numerical and experimental approach to optimise sheet stamping technologies: part II—aluminium alloys rubber-forming. Mater Des 22(4):299–315

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Y., Vu, T.T., Halil, Z. et al. Pressure distribution of serrated contact wheels—experimental and numerical analysis. Int J Adv Manuf Technol 90, 3407–3419 (2017). https://doi.org/10.1007/s00170-016-9630-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9630-0