Abstract

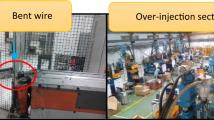

Productivity is a key-factor for companies manufacturing parts and sets to the automotive industry. Automation plays an important role in this matter, allowing development of entire manufacturing cells without the direct need of workers. Even in countries where the labour cost is relatively low, it becomes necessary to improve the level of automation applied to manufacturing cells and reduce the dependence of the human labour unpredictability, also increasing the quality and reducing the costs. This case study was developed based on an industrial request in order to improve a semi-automatic cell devoted to seat suspension mat manufacturing. The original cell allows several automatic operations but it needs two workers for two specific operations not considered in the initial design. Thus, new concepts of wire feeding and manipulation were developed in order to allow a better material flow throughout the cell. The new cell was designed and built with success, allowing to obtain a full-automated system, which leads to a better productivity and reliability of the manufacturing process.

Similar content being viewed by others

References

Leˇskov’a A, Kov’aˇcov’a L (2012) Automotive supply chain outline. Electronic journal Perner’s contacts 7(2):96–104

S. Serdar-Asan, A review of supply chain complexity drivers, Proceedings of the 41st International Conference on Computers & Industrial Engineering, pp. 792–797, Los Angeles, USA (2011)

Darestani SA, Ismail Y, Ismail N, Yusuff RM (2010) An investigation on supplier delivery performance by using SPC techniques for automotive industry. Journal of American Science 6(4):5–11

Holweg M (2008) The evolution of competition in the automotive industry, build to order: the road to the 5-day car. Springer, Berlin, pp. 13–34

Hu SJ (2013) Evolving paradigms of manufacturing: from mass production to mass customization and personalization. Forty Sixth CIRP Conference on Manufacturing Systems 7:3–8

Ribeiro L, Barata J (2011) Re-thinking diagnosis for future automation systems: an analysis of current diagnostic practices and their applicability in emerging IT based production paradigms. Comput Ind 62(7):639–659

Schleich H, Schaffer J, Scavarda LF (2007) Managing complexity in automotive production, 19th International Conference on Production Research. Valparaiso, Chile

He Y, Smith ML, Dudek RA (2010) Robotic material handler scheduling in flexible manufacturing systems for mass costumization. Robot Comput Integr Manuf 26(6):671676

Carpanzano E, Jovane F (2007) Advanced automation solutions for future adaptive factories. Annals of the CIRP 56(1):435–438

Makris S, Chryssolouris G (2013) Web services based supply chain control logic: an automotive case study. Int J Prod Res 52(7):2077–2091

Larsson A (2002) The development and regional significance of the automotive industry: supplier parks in Western Europe. International Journal of Urban and Regional Research 26:767–784

Mourtzis D, Doukas M (2015) On the configuration of supply chains for assembly-to-order products: case studies from the automotive and the CNC machine building sectors. Robotics and Computer Integrated Manufacturing 36:13–24

de Treville S, Shapiro RD, Hameri AP (2004) From supply chain to demand chain: the role of lead time reduction in improving demand chain performance. J Oper Manag 21(6):613–627

Mishina, K., Toyota motor manufacturing. Harvard Business School, case 9–693–019, USA (1995)

H. B. Lary, Imports of manufactures from less developed countries—trade in labor-intensive manufactures, National Bureau of Economic Research, pp. 86–115 (1968)

L. Kromann, J. R. Skaksen and A. Sørensen, Automation, labor productivity and employment a cross country comparison, CEBR, Copenhagen Business School (2011)

Bloom JZ, Lambrechts IJ, le Roux NJ (1998) Distinguishing between capital intensive and labour intensive enterprises listed in the industrial sector of the JSE. Manag Dyn 7(4):39–68

Feldmann K, Mutter B, Haselrnann T (1999) Automated assembly of lightweight automotive components. Annals of CIRP 48(1):9–12

Michalos G, Makris S, Papakostas N, Mourtzis D, Chryssolouris G (2010) Automotive assembly technologies review: challenges and outlook for a flexible and adaptive approach, CIRP. Journal of Manufacturing Science and Technology Vol. 2(No.2):81–91

Jovanel F, Koren Y, Bo¨er CR (2003) Present and future of flexible automation: towards new paradigms. CIRP Ann Manuf Technol Vol. 52(No.2):543–560

Wadhwa RS (2012) Flexibility in manufacturing automation: a living lab case study of Norwegian metal casting SMEs. J Manuf Syst Vol.31(No.4):444–454

A. Mane, S. Nahavandi, J. Zhang, Sequencing production on an assembly line using goal chasing and user defined algorithms, Proceedings of the 2002 Winter Simulation Conference, E. Yucesan, C.-H. Chen, J. L. Snowdon and J. M. Charnes (eds), Vol. 2, pp. 1269–1273 (2002)

S. L. Hunter, Ergonomic evaluation of manufacturing systems designs, Journal of Manufacturing Systems, Vol.20, No.6, pp.429–444 (2001/2002)

P. M. S. Nunes and F. J. G. Silva, Advances in sustainable and competitive manufacturing systems, 23rd International Conference on Flexible Automation and Intelligent Manufacturing, pp.329–340 (2013)

L. Morello, L. R. Rossini, G. Pia and A. Tonoli, The automotive body—volume I: components design, Springer, Cap6, pp. 560–603 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Araújo, W.F.S., Silva, F.J.G., Campilho, R.D.S.G. et al. Manufacturing cushions and suspension mats for vehicle seats: a novel cell concept. Int J Adv Manuf Technol 90, 1539–1545 (2017). https://doi.org/10.1007/s00170-016-9475-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9475-6