Abstract

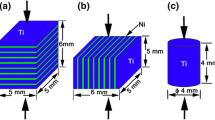

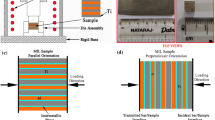

Titanium- and aluminum-based in situ metal intermetallic laminate (MIL) composites were prepared by solid-state diffusion bonding. The transition joints between Ti/Al were made at temperatures 550 and 575 °C with different bonding time under uniaxial pressure of 4 MPa under high vacuum to achieve MILs with different volume fraction of intermetallic phase. The phase and elemental analyses revealed the presence of only TiAl3 intermetallic layer formed between Ti/Al diffusion couple. Also, the layer thickness of the intermetallic phase increased with the increase in both bonding time and temperature. Compression tests were conducted on these MILs at room temperature both parallel and perpendicular to intermetallic layers. The mechanical properties and the failure mode of these MILs were studied based on the volume fraction of intermetallic phase. Results showed that the strength along the parallel direction of the MILs were much higher than the perpendicular direction. The failure mechanism of the MILs also varied based on the volume fraction of the intermetallic phases. Fractography revealed that with high intermetallic content, cracks were formed only on the intermetallic layer irrespective of loading direction. MILs containing intermetallic phase fraction exhibited better work hardening rate and the hardening rate behavior varied with the loading orientation.

Similar content being viewed by others

References

Doychak J (1992) Metal- and intermetallic-matrix composites for aerospace propulsion and power systems. JOM 44(6):46–51. doi:10.1007/BF03222256

Stoloff NS, Liu CT, Deevi SC (2000) Emerging applications of intermetallics. Intermetallics 8:1313–1320. doi:10.1016/S0966-9795(00)00077-7

Yamaguchi M, Inui H, Ito K (2000) High temperature structural intermetallics. Acta Mater 48:307–322. doi:10.1016/S1359-6454(99)00301-8

Vecchio KS (2005) Synthetic multifunctional metal-intermetallic laminate composites. JOM 57(3):25–31. doi:10.1007/s11837-005-0229-4

Xu L, Cui YY, Hao YL, Yang R (2006) Growth of intermetallic layer in multi-laminated Ti/Al diffusion couples. Mater Sci Eng A 435–436:638–647. doi:10.1016/j.msea.2006.07.077

Chaudhari GP, Acoff VL (2010) Titanium aluminide sheets made using roll bonding and reaction annealing. Intermetallics 18:472–478. doi:10.1016/j.intermet.2009.09.008

AlHazaa A, Khan TI, Haq I (2010) Transient liquid phase (TLP) bonding of Al7075 to Ti–6Al–4 V alloy. Mater Charact 61:312–317. doi:10.1016/j.matchar.2009.12.014

Bataev IA, Bataev AA, Mali VI, Pavlyukova DV, Yartsev PS, Golovin ED (2012) Nucleation and growth of titanium aluminide in an explosion welded laminate composite. Phys Met Metallogr 113(10):947–956. doi:10.1134/S0031918X12070022

Lazurenko DV (2015) Metal-intermetallic laminate Ti-Al3Ti composites produced by spark plasma sintering of titanium and aluminum foils enclosed in titanium shells. Metall Mater Trans A 46(9):4326–4334. doi:10.1007/s11661-015-3002-5

Norouzi E, Atapour M, Shamanian M, Allafchian A (2016) Effect of bonding temperature on the microstructure and mechanical properties of Ti-6Al-4V to AISI 304 transient liquid phase bonded joint. Mater Des. doi:10.1016/j.matdes.2016.03.101

Qin B, Sheng GM, Huang JW, Zhou B, Qiu SY, Li C (2006) Phase transformation diffusion bonding of titanium alloy with stainless steel. Mater Charact 56:32–38. doi:10.1016/j.matchar.2005.09.015

Aydin K, Kaya Y, Kahraman N (2012) Experimental study of diffusion welding/bonding of titanium to copper. Mater Des 12:356–368. doi:10.1016/j.matdes.2012.01.026

Konieczny M (2012) Microstructural characterisation and mechanical response of laminated Ni intermetallic composites synthesised using Ni sheets and Al foils. Mater Charact 70:117–124. doi:10.1016/j.matchar.2012.05.007

Kenevisi MS, Mousavi Khoie SM (2012) An investigation on microstructure and mechanical properties of Al7075 to Ti–6Al–4V transient liquid phase (TLP) bonded joint. Mater Des 38:19–25. doi:10.1016/j.matdes.2012.01.046

Fronczek DM, Wojewoda-Budka J, Chulist R, Sypien A, Korneva A, Szulc Z, Schell N, Zieba P (2016) Structural properties of Ti/Al clads manufactured by explosive welding and annealing. Mater Des 91:80–89. doi:10.1016/j.matdes.2015.11.087

Van Loo FJJ, Rieck CD (1973) Diffusion in the titanium-aluminium system—I. Interdiffusion between solid Al and Ti or Ti-Al alloys. Acta Metall 21(1):61–71. doi:10.1016/0001-6160(73)90220-4

Bataev IA, Bataev AA, Mali VI, Pavliukova DV (2012) Structural and mechanical properties of metallic–intermetallic laminate composites produced by explosive welding and annealing. Mater Des 35:225–234. doi:10.1016/j.matdes.2011.09.030

Jiangwei R, Yajiang L, Tao F (2002) Microstructure characteristics in the interface zone of Ti/Al diffusion bonding. Mater Lett 56:647–652. doi:10.1016/S0167-577X(02)00570-0

Mirjalili M, Soltanieh M, Matsuura K, Ohno M (2013) On the kinetics of TiAl3 intermetallic layer formation in the titanium and aluminum diffusion couple. Intermetallics 32:297–302. doi:10.1016/j.intermet.2012.08.017

Peng LM, Wang JH, Li H, Zhao JH, He LH (2005) Synthesis and microstructural characterization of Ti–Al3Ti metal–intermetallic laminate (MIL) composites. Scr Mater 52:243–248. doi:10.1016/j.scriptamat.2004.09.010

Kenevisi MS, Mousavi Khoie SM, Alaei M (2013) Microstructural evaluation and mechanical properties of the diffusion bonded Al/Ti alloys joint. Mech Mater 64:69–75. doi:10.1016/j.mechmat.2013.04.011

Lazurenko DV, Bataev IA, Mali VI, Bataev AA, Maliutina IN, Lozhkin VS, Esikov MA, Jorge AMJ (2016) Explosively welded multilayer Ti-Al composites: structure and transformation during heat treatment. Mater Des. doi:10.1016/j.matdes.2016.04.037

Fan M, Domblesky J, Jin K, Qin L, Cui S, Guo X, Kim N, Tao J (2016) Effect of original layer thicknesses on the interface bonding and mechanical properties of Ti-Al laminate composites. Mater Des. doi:10.1016/j.matdes.2016.03.102

Li T, Jiang F, Olevsky EA, Vecchio KS, Meyers MA (2007) Damage evolution in Ti6Al4V–Al3Ti metalintermetallic laminate composites. Mater Sci Eng A 443(1–2):1–15. doi:10.1016/j.msea.2006.05.037

Price RD, Jiang F, Kulin RM, Vecchio KS (2011) Effects of ductile phase volume fraction on the mechanical properties of Ti–Al3Ti metal-intermetallic laminate (MIL) composites. Mater Sci Eng A 528(7–8):3134–3146. doi:10.1016/j.msea.2010.12.087

Kattner UR, Lin JC, Chang YA (1992) Thermodynamic assessment and calculation of the Ti-AI system. Metallurgical Transactions A 23(8):2081–2090. doi:10.1007/BF02646001

Kocks UF (1976) Laws of work-hardening and low-temperature creep. J Eng Mater Technol 98(1):76–85. doi:10.1115/1.3443340

Mecking H, Kocks UF (1981) Kinetics of flow and strain-hardening. Acta Metall 29(11):1865–1875. doi:10.1016/0001-6160(81)90112-7

Kocks UF, Mecking H (2003) Physics and phenomenology of strain hardening: the FCC case. Prog Mater Sci 48:171–273. doi:10.1016/S0079-6425(02)000038

Chen M, Ma E, Hemker KV, Sheng H, Wang Y, Cheng X (2003) Deformation twinning in nanocrystalline aluminum. Science 300(5623):1275–1277. doi:10.1126/science.1083727

Liao XZ, Zhou F, Lavernia EJ, He DW, Zhu YT (2003) Deformation twins in nanocrystalline Al. Appl Phys Lett 83(24):5062–5064. doi:10.1063/1.1633975

Zhao F, Wang L, Fan D, Bie BX, Zhou XM, Suo T, Li YL, Chen MW, Liu CL, Qi ML, Zhu MH, Luo SN (2016) Macrodeformation twins in single-crystal aluminum. Phys Rev Lett 116:075501. doi:10.1103/PhysRevLett.116.075501

Asgari S, El-Danaf E, Kalidindi SR, Doherty RD (1997) Strain hardening regimes and microstructural evolution during large strain compression of low stacking fault energy FCC alloys that form deformation twins. Metall Mater Trans A 28(9):1781–1795. doi:10.1007/s11661-997-0109-3

Salem AA, Kalidindi SR, Doherty RD (2002) Strain hardening regimes and microstructure evolution during large strain compression of high purity titanium. Scr Mater 46(6):419–423. doi:10.1016/S1359-6462(02)00005-2

Ahn K, Huh H, Yoon J (2013) Strain hardening model of pure titanium considering effects of deformation twinning. Met Mater Int 19(4):749–758. doi:10.1007/s12540-013-4014-6

Salem AA, Kalidindi SR, Doherty RD (2003) Strain hardening of titanium: role of deformation twinning. Acta Mater 51(14):4225–4237. doi:10.1016/S1359-6454(03)00239-8

Salem AA, Kalidindi SR, Doherty RD, Semiatin SL (2006) Strain hardening due to deformation twinning in α-titanium: mechanisms. Metall Mater Trans A 37(1):259–268. doi:10.1007/s11661-006-0171-2

Caceres CH, Blake AH (2007) On the strain hardening behaviour of magnesium at room temperature. Material science and Engineering A 462(1–2):193–196. doi:10.1016/j.msea.2005.12.113

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thiyaneshwaran, N., Sivaprasad, K. & Ravisankar, B. Work hardening behavior of Ti/Al-based metal intermetallic laminates. Int J Adv Manuf Technol 93, 361–374 (2017). https://doi.org/10.1007/s00170-016-9382-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9382-x