Abstract

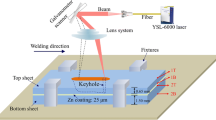

This work investigates the use of a trifocal laser intensity distribution to control the applied heat profile for laser brazing of hot-dip galvanized steel. Process analysis of conventional monofocal brazing processes showed that spatter and other process disruptions mainly originate from zinc dissolution and evaporation at the wetting line. In order to increase process stability and seam quality, a trifocal brazing method was developed and applied for brazing experiments. A transient three-dimensional model of the brazing processes shows a shift of the achieved temperature distribution and thus a separated evaporation of the zinc coating prior to the wetting with molten CuSi3 brass. The influence of the adjusted intensity distribution in the process area was analyzed with high-speed video imaging, thermal imaging, and metallographic analysis of the seam properties. The experimental analysis confirms that during trifocal brazing, a local zinc evaporation takes place prior to the spreading of the molten filler metal. As a result, a less turbulent processing zone and a superior seam quality are attained.

Similar content being viewed by others

References

Graudenz M, Heitmanek M (2012) Laser tools in the manufacturing process. Laser Tech J 9:24–27. doi:10.1002.latj.201290049

Ungers M, Fecker D, Frank S, Donst D, Märgner V, Abels P, Kaierle S (2010) In-situ quality monitoring during laser brazing. Phys Procedia 5:493503. doi:10.1016/j.phpro.2010.08.077

Fenggui L, Binfeng L, Xinhua T, Shun Y (2008) Study of influencing factors and joint performance of laser brazing on zinc-coated steel plate. Int J Adv Manuf Technol 37:961965. doi:10.1007/s00170-007-1035-7

Grimm A, Schmid M (2009) Possibilities for online process monitoring at laser brazing based on two dimensional detector systems. In: Xinbing L (ed) Conference proceedings ICALEO, vol 2009. Laser Institute of America, Orlando, pp 537– 544

Kimura S, Takemura S, Mizutani M, Katayama S (2006) Laser brazing phenomena of galvanized steel and pit formation mechanism. In: Ostendorf A (ed) Conference proceedings ICALEO, vol 2006. Laser Institute of America, Orlando, pp 346– 354

Koltsov A, Bailly N, Cretteur L (2010) Wetting and laser brazing of Zn-coated steel products by CuSi filler metal. J Mater Sci 45:21182125. doi:10.1007/s10853-009-3949-y

Gatzen M, Radel T, Thomy C, Vollertsen F (2014) The role of zinc layer during wetting of aluminium on zinc-coated steel in laser brazing and welding. Phys Procedia 56:730739. doi:10.1016/j.phpro.2014.08.080

Gatzen M, Radel T, Thomy C, Vollertsen F (2014) Wetting behavior of eutectic AlSi droplets on zinc coated steel substrates. J Mater Process Technol 214:123131. doi:10.1016/j.jmatprotec.2013.08.005

Heyn H (2003) Laserstrahllöten von verzinktem Stahl - Einfluss der Oberflächenbeschichtung. EALA - European Automotive Laser Applications, 08.04.2003, Bad Nauheim

Schmidt M, Otto A, Kägeler C (2008) Analysis of YAG laser lap-welding of zinc coated steel sheets. CIRP Ann - Manuf Technol 57:213216. doi:10.1016/j.cirp.2008.03.043

Roos C, Schmidt M (2014) Remote laser welding of zinc coated steel sheets in an edge lap configuration with zero gap. Phys Procedia 56:535544. doi:10.1016/j.phpro.2014.08.025

Hesse T (2008) Neue Erkenntnisse und Lösungs-grundlagen beim Laserstrahlschweißen von verzinkten Werkstoffen. European Automotive Laser Applications, 31.01.2008, Bad Nauheim

Rito N, Ohta M, Yamada T, Gotoh J, Kitagawa T (1988) Laser welding method. US patent 4745257 A

AlShaer A W, Li L, Mistry A (2014) The effects of short pulse laser surface cleaning on porosity formation and reduction in laser welding of aluminium alloy for automotive component manufacture. Opt Laser Technol 64:162–171. doi:10.1016/j.optlastec.2014.05.010

Milberg J, Trautmann A (2009) Defect-free joining of zinc-coated steels by bifocal hybrid laser welding. Prod Eng 3:9–15. doi:10.1007/s11740-008-0140-2

Kögel G (2014) Kurzpulslaser machen tailored welded blanks fit für das Presshärten. Blech 04:18–24

Donst D (2012) Entwicklung eines Zweistrahlverfahrens zum flussmittelfreien Laserstrahlhartlöten von Alumini-umblechwerkstoffen. Dissertation, RWTH Aachen

Frank S (2015) Flux-free laser joining of aluminum and galvanized steel. J Mater Process Technol 222:365372. doi:10.1016/j.jmatprotec.2015.03.032

Hanebuth (1996) Laserstrahlhartlöten mit Zwei-strahltechnik. Dissertation, Friedrich Alexander Universität Erlangen Nürnberg

Hoffmann P, Hornig H, Berndl J (2006) Mehrstrahllaserbearbeitungskopf. European patent 1935552 B1

Hoffmann P, Schwab J, Foertschbeck E (2004) Twins spot technology for an advanced laser brazing process. In: Geiger M, Otto A (eds) Proceedings of the 4th LANE. Meisenbach-Verlag, Bamberg, pp 259–262

Grimm A, Schmidt M, Hoffmann P (2010) Laserstrahllöten mit Koaxialer Drahtzuführung. In: DVS-Berichte Band, vol 267. DVS Media, Düsseldorf, p 312320

Mittelstädt C, Seefeld T, Reitemeyer D, Vollertsen F (2014) Two-beam laser brazing of thin sheet steel for automotive industry using Cu-base filler material. Phys Procedia 56:699708. doi:10.1016/j.phpro.2014.08.077

Heitmanek M, Dobler M, Graudenz M, Perret W, Göbel G, Schmidt M, Beyer E (2014) Laser brazing with beam scanning: Experimental and simulative analysis. Phys Procedia 56:689698. doi:10.1016/j.phpro.2014.08.076

Victor B, Farson F, Ream S, Walters C (2011) Custom beam shaping for high-power fiber laser welding. Weld J 90:113120

Goffin N, Higginson R, Tyrer J (2015) The use of holographic optical elements (HOE’s) to investigate the use of a flat irradiance profile in the control of heat absorption in wire-fed laser cladding. J Mater Process Technol 220:191201. doi:10.1016/j.jmatprotec.2015.01.023

Chen S, Li L, Chen Y, Daic J, Huang J (2011) Improving interfacial reaction nonhomogeneity during laser weldingbrazing aluminum to titanium. Mater Des 32:44084416. doi:10.1016/j.matdes.2011.03.074

Li L, Feng X, Chen Y (2008) Influence of laser energy input mode on joint interface characteristics in laser brazing with Cu-base filler metal. Trans Nonferrous Metals Soc China 18:10651070. doi:10.1016/S1003-6326(08)60182-X

Hansen K, Kristiansen M, Olsen F (2014) Beam shaping to control of weldpool size in width and depth. Phys Procedia 56:467476. doi:10.1016/j.phpro.2014.08.150

Weller H, Tabor G, Jasak H, Fureby C (1998) A tensorial approach to computational continuum mechanics using objectoriented techniques. Comput Phys 12:620–631. doi:10.1063/1.168744

Dobler M, Leitz K, Otto A, Schmidt M (2013) Simulation of process dynamics in laser beam brazing. In: Kaierle S (ed) Conference proceedings ICALEO, vol 2013. Laser Institute of America, Orlando, pp 85–90

Saunders N, Guo U, Li X, Miodownik A, Schillé J (2003) Using JMatPro to model materials properties and behavior. J Miner Met Mater Soc 55:60–65. doi:10.1007/s11837-003-0013-2

Kai M, Zhishui Y, Peilei Z, Yunlong L, Hua L, Chonggui L, Xiaopeng L (2015) Influence of wire feeding speed on laser brazing zinc-coated steel with Cu-based filler metal. Int J Adv Manuf Technol 76:13331342. doi:10.1007/s00170-014-6347-9

Jia L, Shichun J, Yan S, Cong N, Junke C, Genzhe H (2015) Effects of zinc on the laser welding of an aluminum alloy and galvanized steel. J Mater Process Technol 224:4959. doi:10.1016/j.jmatprotec.2015.04.017

Eustathopoulus N, Nicolas M, Drevet B (1999) Wettability at high temperatures. Elsevier, Oxford, pp 348–382

Marder A (2000) The metallurgy of zinc-coated steel. Prog Mater Sci 45:191271. doi:10.1016/S0079-6425(98)00006-1

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reimann, W., Dobler, M., Goede, M. et al. Three-beam laser brazing of zinc-coated steel. Int J Adv Manuf Technol 90, 317–328 (2017). https://doi.org/10.1007/s00170-016-9361-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9361-2