Abstract

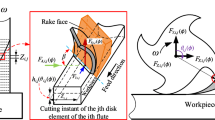

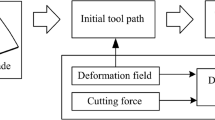

A mathematical model of cutting force is established to illustrate the characteristics in micro milling process of copper thin wall structure. The deformation of thin wall is predicted by means of finite element analysis. Experiments are carried out to confirm the validity of the model in which a diamond-coated micro milling cutter with a 0.5-mm diameter is used. Deformation and micro burrs are induced using different parameters and machining methods. Experimental results show that the proposed mathematical model and analysis methods can effectively predict the machining deformation of a micro thin wall. There is a close correspondence between the position of applied load and deformation of a thin wall. Not only the sizes of burrs and deformation are smaller but also the quality is better for the down-milling of copper thin wall structure than the up-milling. With decreasing the cutting thickness, the surface quality is improved.

Similar content being viewed by others

References

Chae J, Park SS, Freiheit T (2006) Investigation of micro-cutting operations. Int J Mach Tools Manuf 46(3):313–332

Liu X, DeVor RE, Kapoor SG, Ehmann KF (2004) The mechanics of machining at the microscale: assessment of the current state of the science. J Manuf Sci Eng 126(4):666–678

Vogler MP, DeVor RE, Kapoor SG (2003) Microstructure-level force prediction model for micro-milling of multi-phase materials. J Manuf Sci Eng 125(2):202–209

Liu Y, Li TX, Liu K, Zhang YM (2016) Chatter reliability prediction of turning process system with uncertainties. Mech Syst Signal Process 66:232–247

Li P, Zdebski D, Langen HH, Hoogstrate AM (2010) Micromilling of thin ribs with high aspect ratios. J Micromech Microeng 20(11):115013

Annoni M, Petrò S, Rebaioli L, Semeraro Q, Solito R, (2012) Micromilling strategies impact on thin walls geometrical quality, 4M 2012 - 9th International Conference on Multi-Material Micro Manufacture, Wien (Austria)..

Budak E (2006) Analytical models for high performance milling, Part II: process dynamics and stability, International Journal of Machine Tools and Manufacture, in press.46(12):1478–1488

Tang AJ, Liu ZQ (2008) Deformations of thin-walled plate due to static end milling force. J Mater Process Technol 206(1):345–351

Liu G (2009) Study on deformation of titanium thin-walled part in milling process. J Mater Process Technol 209(6):2788–2793

Wan M, Zhang WH, Qin GH, Tan G (2007) Efficient calibration of instantaneous cutting force coefficients and runout parameters for general end mills. Int J Mach Tools Manuf 47(11):1767–1776

Wan M, Zhang WH, Tan G, Qin GH (2007) An in-depth analysis of the synchronization between the measured and predicted cutting forces for developing instantaneous milling force model. Int J Mach Tools Manuf 47(12):2018–2030

Loehe J, Zaeh MF, Roesch O (2012) In-process deformation measurement of thin-walled workpieces. Procedia CIRP 1:546–551

Friedrich CR, Vasile MJ (1996) Development of the micromilling process for high-aspect-ratio microstructures. J Microelectromech Syst 5(1):33–38

Friedrich CR (2002) Micromechanical machining of high aspect ratio prototypes. Microsyst Technol 8(4–5):343–347

Bang Y, Lee K, Oh S (2005) 5-axis micro milling machine for machining micro parts. Int J Adv Manuf Technol 25(9–10):888–894

Chern GL, Wu YJE, Cheng JC, Yao JC (2007) Study on burr formation in micro-machining using micro-tools fabricated by micro-EDM. Precis Eng 31(2):122–129

Jin X, Altintas Y (2012) Prediction of micro-milling forces with finite element method. J Mater Process Technol 212(3):542–552

Huo D, Lin C, Choong ZJ, Pancholi K, Degenaar P (2015) Surface and subsurface characterisation in micro-milling of monocrystalline silicon. Int J Adv Manuf Technol 81(5–8):1319–1331

da Silva LC, da Mota PR, da Silva MB, Ezugwu EO, Machado ÁR (2015) Study of burr behavior in face milling of PH 13-8 Mo stainless steel. CIRP J Manuf Sci Technol 8:34–42

da Silva LC, da Mota PR, da Silva MB, Ezugwu EO, Machado ÁR (2015) Study of burr height in face milling of PH 13-8 Mo stainless steel––transition from primary to secondary burr and benefits of deburring between passes. CIRP J Manuf Sci Technol 10:61–67

Wen XL, Gong YD, Cheng J, Ba DC (2015) Mechanism analysis and experiment al research on wear of electroplated diamond micro-grinding tool. Journal of Mechanical Engineering 51(11):177–185

Reddy NSK, Rao PV (2006) Selection of an optimal parametric combination for achieving a better surface finish in dry milling using genetic algorithms. Int J Adv Manuf Technol 28(5–6):463–473

Piquard R, D’Acunto A, Laheurte P, Dudzinski D (2014) Micro-end milling of NiTi biomedical alloys, burr formation and phase transformation. Precis Eng 38(2):356–364

Malekian M, Park SS, Jun MBG (2009) Modeling of dynamic micro-milling cutting forces. Int J Mach Tools Manuf 49(7):586–598

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Li, P., Liu, K. et al. Micro milling of copper thin wall structure. Int J Adv Manuf Technol 90, 405–412 (2017). https://doi.org/10.1007/s00170-016-9334-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9334-5