Abstract

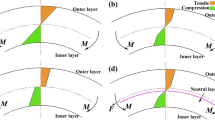

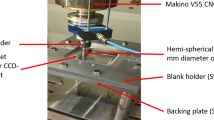

In this paper, the springback of the aluminium alloy AA5754 under hot stamping conditions was characterised under stretch and pure bending conditions. It was found that elevated temperature stamping was beneficial for springback reduction, particularly when using hot dies. Using cold dies, the flange springback angle decreased by 9.7 % when the blank temperature was increased from 20 to 450 °C, compared to the 44.1 % springback reduction when hot dies were used. Various other forming conditions were also tested, the results of which were used to verify finite element (FE) simulations of the processes in order to consolidate the knowledge of springback. By analysing the tangential stress distributions along the formed part in the FE models, it was found that the springback angle is a linear function of the average through-thickness stress gradient, regardless of the forming conditions used.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Lutsey NP (2010) Review of technical literature and trends related to automobile mass-reduction technology, in. Institute of Transportation Studies, UC Davis

Garrett RP, Lin J, Dean TA (2005) An investigation of the effects of solution heat treatment on mechanical properties for AA 6xxx alloys: experimentation and modelling. Int J Plast 21:1640–1657

Z. Shi, Y. Wang, J. Lin, T.A. Dean, D. Balint, M. Stanton, D. Watson 2012 An investigation, using standard experimental techniques, to determine FLCs at elevated temperature for aluminium alloys, in: The 3rd International Conference on New Forming Technology, Harbin, China

Li DM, Ghosh AK (2004) Effects of temperature and blank holding force on biaxial forming behavior of aluminum sheet alloys. J Mater Eng Perform 13:348–360

Palumbo G, Tricarico L (2007) Numerical and experimental investigations on the warm deep drawing process of circular aluminum alloy specimens. J Mater Process Technol 184:115–123

Toros S, Ozturk F, Kacar I (2008) Review of warm forming of aluminum-magnesium alloys. J Mater Process Technol 207:1–12

Wang L, Strangwood M, Balint D, Lin J, Dean TA (2011) Formability and failure mechanisms of AA2024 under hot forming conditions. Mater Sci Eng A-Struct Mater Prop Microstruct Process 528:2648–2656

N. Li, M.S. Mohamed, J. Cai, J. Lin, D. Balint, T.A. Dean (2011) Experimental and numerical studies on the formability of materials in hot stamping and cold die quenching processes, 14th International Conference on Material Forming Esaform, 2011 Proceedings, 1353, 1555–1561

Chen G, Chen M, Wang N, Sun J (2015) Hot forming process with synchronous cooling for AA2024 aluminum alloy and its application. Int J Adv Manuf Technol:1–7

Liang J, Gao S, Teng F, Yu P, Song X (2014) Flexible 3D stretch-bending technology for aluminum profile. Int J Adv Manuf Technol 71:1939–1947

J.L. L. Wang, O. El Fakir, A. Foster, G. Adam and J. Sellors (2013) HFQ forming: a novel lightweight sheet metal forming technology for mass-production, in: TTP2013 tools and technologies for processing ultra high strength materials., Austria, Graz

J.C. H. Laurent, R. Greze, P. Y. Manach, A. Andrade-Campos, M. C. Oliveira and L. F. Menezes (2011) Mechanical behaviour and springback study of an aluminium alloy in warm forming conditions, International Scholarly Research Network, 2011 Article ID 381615, 381619 pages

T.A.D. J. Lin, R.P. Garrett and F.A. D. (2008) A process in forming high strength and complex-shaped Al-alloy sheet components, in: B. Patent (Ed.), UK

D.B. J. Lin, L. Wang, T.A. Dean and A.D. Foster (2011) Method for forming component of complex shape from aluminum-alloy sheet, involves quenching heated sheets between cold dies in solution and maintaining shape of sheet, Imperial Innovations Ltd (Unlo), pp. 2499271-A2499271

Keum YT, Han BY (2002) Springback of FCC sheet in warm forming. J Ceram Process Res 3:159–165

Moon YH, Kang SS, Cho JR, Kim TG (2003) Effect of tool temperature on the reduction of the springback of aluminum sheets. J Mater Process Technol 132:365–368

Kim HS, Koç M (2008) Numerical investigations on springback characteristics of aluminum sheet metal alloys in warm forming conditions. J Mater Process Technol 204:370–383

D.W.a.R.R. I.G. Masters (2009) Modelling springback—a review, in: The 7th International Conference on Manufacturing Research (ICMR09), University of Warwick, Coventry

F. Fraunhofer-Institut für Werkstoffmechanik IWM, Springback of hat profiles, in.

R.B. M.Stanton, G.Williams and I.Dargue 2009 Investigation of materials springback using a simple U-profile, in, University of Warwick

Novelis, Mill certificate.

El Fakir O, Wang L, Balint D, Dear JP, Lin J, Dean TA (2014) Numerical study of the solution heat treatment, forming, and in-die quenching (HFQ) process on AA5754. Int J Mach Tools Manuf 87:39–48

Mohamed MS, Foster AD, Lin JG, Balint DS, Dean TA (2012) Investigation of deformation and failure features of AA6082: experimentation and modelling. Int J Mach Tools Manuf 53:27–38

Z. Shi, L. Wang, M. Mohamed, J.Lin, D. Balint, T.A Dean (2009) Friction at warm forming conditions, internal report

Foster AD, Mohamed MS, Lin JG, Dean TA (2008) An investigation of lubrication and heat transfer for a sheet aluminium heat, form-quench (HFQ) process. Steel Res Int 113-120

C. Edupack 2012 English level − 3-metal alloy-non-ferrous-aluminium-wrought-5454

Oliveira MC, Alves JL, Chaparro BM, Menezes LF (2007) Study on the influence of work-hardening modeling in springback prediction. Int J Plast 23:516–543

Chen FK, Ko SF (2011) Deformation analysis of springback in L-bending of sheet metal. Adv Sci Lett 4:1928–1932

Wagoner RH, Lim H, Lee M-G (2013) Advanced issues in springback. Int J Plast 45:3–20

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wang, A., Zhong, K., El Fakir, O. et al. Springback analysis of AA5754 after hot stamping: experiments and FE modelling. Int J Adv Manuf Technol 89, 1339–1352 (2017). https://doi.org/10.1007/s00170-016-9166-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9166-3