Abstract

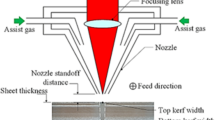

Modern day industries face a stiff challenge in cutting advanced materials like metal matrix composites with desired surface quality. The present work investigates the possibility of obtaining good quality characteristics (surface roughness and kerf width) with pulsed CO2 laser cutting of Al6061/Al2O3 composite. The parameters involved in this non-contact type cutting process like the beam power, assist gas pressure, flow rate of assist gas, pulsing frequency and speed of spot movement were varied according to a structured L27 orthogonal array, and the quality characteristics including surface finish and kerf width were observed. Response surface methodology (RSM) was applied to generate quadratic models for the observed quality characteristics, and desirability analysis was used to obtain the optimal setting of laser cutting parameters. Field emission scanning electron microscope (FESEM) images, EDX plot and P-profile graphs were also examined to study the cut surfaces.

Similar content being viewed by others

References

Gururaja S, Ramulu M, Pedersen W (2013) Machining of MMCs: a review. Mach Sci Technol 17(7):41–73

Adalarasan R, Santhanakumar M, Rajmohan M (2015) Optimization of laser cutting parameters for Al6061/SiCp/Al2O3 composite using grey based response surface methodology (GRSM). Measurement 73(1):596–606

Ren D, Narayan RJ, Lee Y (2009) Machined surface error analysis for laser micromachining of biocompatible polymers for medical devices manufacturing. Comput-Aided Design Appl 6(6):781–793

Dubey AK, Yadava V (2008) Laser beam machining—a review. Int J MachTools Manuf 48(6):609–628

Sharma A, Yadava V (2011) Optimization of cut quality characteristics during Nd:YAG laser straight cutting of Ni-based superalloy thin sheet using grey relational analysis with entropy measurement. Mater Manuf Process 26(12):1522–1529

Shi A, Attia H, Vargas R, Tavakoli S (2008) Numerical and experimental investigation of laser-assisted machining of inconel 718. Mach Sci Technol 12(4):498–513

Ding H, Shin YC (2013) Improving machinability of high chromium wear-resistant materials via laser-assisted machining. Mach Sci Technol 17(2):246–269

Kurt M, Kaynak Y, Bagci E, Demirer H, Kurt M (2009) Dimensional analyses and surface quality of the laser cutting process for engineering plastics. Int J Adv Manuf Technol 41(3–4):259–267

Scintilla LD, Palumbo G, Sorgente D, Tricarico L (2013) Fiber laser cutting of Ti6Al4V sheets for subsequent welding operations: effect of cutting parameters on butt joints mechanical properties and strain behaviour. Mater Des 47:300–308

Biswas R, Kuar AS, Biswas SK, Mitra S (2010) Effects of process parameters on hole circularity and taper in pulsed Nd:YAG laser microdrilling of Tin-Al2O3 composites. Mater Manuf Process 25(6):503–514

Islam MU, Campbell G (1993) Laser machining of ceramics: a review. Mater Manuf Process 8(6):611–630

Kumpulainen T, Karjalainen I, Prusi T, Holsa J, Heikkila R, Tuokko R (2009) Pulsed laser machining implemented with piezoelectric actuator. Int J Optomechatronics 8(6):1–17

Eltawahni HA, Rossini NS, Dassisti M, Alrashed K, Aldaham TA, Benyounis KY, Olabi AG (2013) Evaluation and optimization of laser cutting parameters for plywood materials. Opt Laser Eng 51(9):1029–1043

Santhanakumar M, Adalarasan R, Rajmohan M (2015) Experimental modelling and analysis in abrasive waterjet cutting of ceramic tiles using grey-based response surface methodology. Arab J Sci Eng 40(11):3299–3311

Adalarasan R, Santhanakumar M (2015) Application of Taguchi based response surface method (trsm) for optimization of multi responses in drilling Al/SiC/Al2O3 hybrid composite. J Inst Eng (India): Series C 96(1):65–71

Adalarasan R, Santhanakumar M, Rajmohan M (2015) Application of Grey Taguchi-based response surface methodology (GT-RSM) for optimizing the plasma arc cutting parameters of 304L stainless steel. Int J Adv Manuf Technol 78(5–8):1161–1170

Lal S, Kumar S, Khan ZA, Siddiquee AN (2014) Wire electrical discharge machining of AA7075/SiC/Al2O3 hybrid composite fabricated by inert gas-assisted electromagnetic stir-casting process. J Braz Soc Mech Sci Eng 36(2):335–346

Aghdeab SH, Mohammed LA, Ubaid AM (2015) Optimization of CNC turning for aluminum alloy using simulated annealing method. Jordan J Mech Indl Eng 9(1):39–44

Yang CB, Deng CS, Chiang HL (2012) Combining the Taguchi method with artificial neural network to construct a prediction model of a CO2 laser cutting experiment. Int J Adv Manuf Technol 59(9–12):1103–1111

Karthikeyan R, Adalarasan R, Pai BC (2002) Optimization of machining characteristics for Al/SiCp composites using ANN/GA. J Mater Sci Technol 18(1):47–50

Yilbas BS, Khan S, Raza K, Keles O, Ubeyli M, Demir T, Karakas MS (2010) Laser cutting of 7050 Al alloy reinforced with Al2O3 and B4C composites. Int J Adv Manuf Technol 50(1–4):185–193

Yilbas BS, Akhtar SS, Karatas C (2013) Laser cutting of alumina tiles: heating and stress analysis. J Manuf Process 15(1):14–24

Yilbas BS, Akhtar SS (2011) Laser cutting of alloy steel: three-dimensional modeling of temperature and stress fields. Mater Manuf Process 26(1):104–112

Santhanakumar M, Adalarasan R, Rajmohan M (2016) Parameter design for cut surface characteristics in abrasive waterjet cutting of Al/SiC/Al2O3 composite using grey theory based RSM. J Mech Sci Technol 30(1):371–379

Kalaimathi M, Venkatachalam G, Sivakumar M (2014) Experimental investigations on the electrochemical machining characteristics of monel 400 alloys and optimization of process parameters. Jordan J Mech Ind Eng 8(3):143–151

Sivarao S, Milkey KR, Samsudin ARN, Dubey AKN, Kidd PN (2014) Comparison between Taguchi method and response surface methodology (RSM) in modelling CO2 laser machining. Jordan J Mech nd Eng 8(1):35–42

Solaiyappan A, Mani K, Gopalan V (2014) Multi-objective for electrochemical machining of 6061Al/10%Wt Al2O3/5%Wt SiC composite using hybrid fuzzy-artificial bee colony algorithm. Jordan J Mech Ind Eng 8(5):323–331

Lum KCP, Ng SL, Black I (2000) CO2 laser cutting of MDF: 1. determination of process parameter settings. Optics Laser Technol 42(1):67–76

Al-Sulaiman F, Yilbas BS, Ahsan M, Karatas C (2009) CO2 laser cutting of Kevlar laminate: influence of assisting gas pressure. Int J Adv Manuf Technol 45(1–2):62–70

Yan Y, Ji L, Bao Y, Chen X, Jiang Y (2013) CO2 laser high-speed crack-free cutting of thick-section alumina based on close-piercing lapping technique. Int J Adv Manuf Technol 64(9–12):1611–1624

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adalarasan, R., Santhanakumar, M. & Thileepan, S. Selection of optimal machining parameters in pulsed CO2 laser cutting of Al6061/Al2O3 composite using Taguchi-based response surface methodology (T-RSM). Int J Adv Manuf Technol 93, 305–317 (2017). https://doi.org/10.1007/s00170-016-8978-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8978-5