Abstract

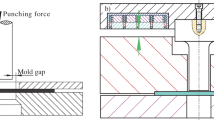

In this work, experimental and numerical simulation of high-speed inward forming of tubes on a die in electromagnetic forming (EMF) system using a compression coil is presented. A 2D axi-symmetric electromagnetic model is used to calculate magnetic field and magnetic forces. Modified loose-coupled simulations of electromagnetic and structural aspects of EMF process are reported and emphasized in this paper. During the simulation, in each time step, the transient magnetic forces are obtained from the electromagnetic model and used as input load to the mechanical model. Based on the calculated deformation, in each step, the tube geometry in the electromagnetic model is updated to calculate the electromagnetic forces in proceeding step. Tube material, AA 6061-T6, is assumed to obey the Johnson-Cook (J-C) rate-dependent model. Displacement and thickness variations of workpieces along the tube length are presented and discussed experimentally and numerically. The results demonstrate that various workpiece zones could be thickened or thinned based on various process parameters. In addition, it is seen that the increase of discharge voltage decreases the thickness at die radius and reverses the thickening trend at tip of the bead.

Similar content being viewed by others

References

Chunfeng L, Zhiheng Z, Jianhui L, Yongzhi W, Yuying Y (2002) Numerical simulation of the magnetic pressure in tube electromagnetic bulging. J Mater Process Technol 123:225–228

El-Azab A, Garnich M, Kapoor A (2003) Modeling of the electromagnetic forming of sheet metals: state-of-the-art and future needs. J Mater Process Technol 142:744–754

Murakoshi Y, Takahashi M, Sano T, Hanada K, Negishi H (1998) Inside bead forming of aluminum tube by electro-magnetic forming. J Mater Process Technol 80–8:695–699

Oliveira DA, Worswick MJ, Finn M, Newman D (2005) Electromagnetic forming of aluminum alloy sheet: free-form and cavity fill experiments and model. J Mater Process Technol 170:350–362

Triantafyllidis N, Waldenmyer JR (2004) Onset of necking in electro-magnetically formed rings. J Mech Phys Solids 52:2127–2148

Jimbert P, Eguia I (2015) Improving the electromagnetic forming process efficiency for steel parts by electrolytic coating. DYNA 90(4):383–392. doi:10.6036/7364

Bruno EJ (1968) High velocity forming of metals. ASTM Publication, Michigan

Correia JPM, Siddiqui MA, Ahzi S, Belouettar S, Davies R (2008) A simple model to simulate electromagnetic sheet free bulging process. Int J Mech Sci 50:1466–1475

Mamalis AG, Manolakos DE, Kladas AG, Koumoutsos AK (2004) Electromagnetic forming and powder processing: trends and developments. Appl Mech Rev 57:299–324

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming—a review. J Mater Process Technol 211:787–829

Takatsu N, Kato M, Sato K, Tobe T (1988) High speed forming of metal sheets by electromagnetic forces. Jpn Soc Mech Eng Int J 60:142–148

Cui X, Mo J, Xiao Sh DE, Zhao J (2011) Numerical simulation of electromagnetic sheet bulging based on FEM. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3273-y

Cui X, Mo J, Han F (2012) 3D Multi-physics field simulation of electromagnetic tube forming. Int J Adv Manuf Technol 59:521–529. doi:10.1007/s00170-011-3540-y

Bay F, Labbe V, Favennec Y, Chenot JL (2003) A numerical model for induction heating processes coupling electromagnetism and thermo mechanics. Int J Numer Methods Eng 58:839–867

Imbert JM, Winkler SL, Worswick MJ, Oliveira DA, Golovashchenko S (2004) Numerical study of damage evolution and failure in an electromagnetic corner fill operation. Proceedings of the 8th Int conference on numerical methods in industrial forming processes, NUMIFORM 2004, Columbus:1833–1838

Wang L, Chen ZY, Li CX, Huang SY (2006) Numerical simulation of the electromagnetic sheet metal bulging process. Int J Adv Manuf Technol 30:395–400

Li F, Mo J, Zhou H, Fang Y (2013) 3D Numerical simulation method of electromagnetic forming for low conductive metals with a driver. Int J Adv Manuf Technol 64:1575–1585. doi:10.1007/s00170-012-4124-1

Al-Hassani STS (1975) Magnetic pressure distribution in the sheet metal forming. Electrical Methods of Machining, Proceedings of the Forming and coating conference, Institute of electrical engineering:1–10

Pérez I, Aranguren I, González B, Eguia I (2009) Electromagnetic forming: a new coupling method. Int J Mater Form 2:637–640

Siddiqui MA, Correia JPM, Ahzi S, Belouettar S (2008) A numerical model to simulate electromagnetic sheet metal forming process. Int J Mater Form 1:1387–1390

Cui X, Mo J, Li J, Huang L, Zhu Y, Li ZW, Zhong K (2013) Effect of second current pulse and different algorithms on simulation accuracy for electromagnetic sheet forming. Int J Adv Manuf Technol 68:1137–1146

Haiping Y, Chunfeng L, Jianghua D (2009) Sequential coupling simulation for electromagnetic–mechanical tube compression by finite element analysis. J Mater Process Technol 209:707–713

Bartels G, Schatzing W, Scheibe HP, Leone M (2009) Comparison of two different simulation algorithms for the electromagnetic tube compression. Int J Mater Form 2(1):693–696

Cao Q, Li L, Lai Z, Zhou Z, Xiong Q, Zhang X, Han X (2014) Dynamic analysis of electromagnetic sheet metal forming process using finite element method. Int J Adv Manuf Technol 74:361–368

Vivek A, Kim KH, Daehn GS (2010) Simulation and instrumentation of electromagnetic compression of steel tubes. J Mater Process Technol. doi:10.1016/j.jmatprotec.2010.08.023

Fallahi AA, Ebrahimi HH, Farzin M (2012) Numerical and experimental investigation of inward tube electromagnetic forming—electromagnetic study. Adv Mater Res 383–390:6710–6716. doi:10.4028/www.scientific.net/AMR.383-390.6710

Dariani BM, Liaghat GH, Gerdooei M (2009) Experimental investigation of sheet metal formability under various strain rates. Proc IMechE Vol 223 Part B: J Engineering Manufacture IMechE 2009:1–10

Johnson GR and Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proc 7th Int Symposium on Ballistics 541–547

Lesuer DR, Kay GJ, LeBlanc MM (2001) Modeling large-strain, high-rate deformation in metals. Technical Report UCRL-JC-134118, Lawrence Livermore National Laboratory, Livermore

Corbett BM (2006) Numerical simulations of target hole diameters for hypervelocity impacts into elevated and room temperature bumpers. Int J Impact Eng 33:431–440

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haratmeh, H.E., Arezoodar, A.F. & Farzin, M. Numerical and experimental investigation of inward tube electromagnetic forming. Int J Adv Manuf Technol 88, 1175–1185 (2017). https://doi.org/10.1007/s00170-016-8826-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8826-7