Abstract

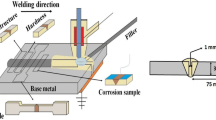

This study addressed the comparison of microstructures and mechanical properties of gas tungsten arc welding (GTAW) of 443 super pure ferritic stainless steel which are protected by three different kinds of shielding gas during welding process: pure argon, argon in the inner layer combined with nitrogen in the outer layer (simple double-layer gas), and argon-5 %nitrogen in the inner layer combined with nitrogen in the outer layer (mixed double-layer gas). As a result, in the center of the welds protected by nitrogen and argon, it formed equiaxed grains which achieving the purpose of grain refinement, while there were all columnar grains in the weld protected by pure argon. The experimental results showed that the depth/width ratio of the welds shielded by simple double-layer gas had been increased. Additionally, with the addition of nitrogen in the shielding gas, the hardness and impact toughness of the weld metal and heat-affected zone (HAZ) were improved when the heat input was the same. The relationships between microstructures and mechanical properties of 443 ferritic stainless steel joints were studied by optical microscope and scanning electron microscope combined with energy-dispersive spectrometer.

Similar content being viewed by others

References

Mallaiah G, Kumar A, Ravinder Reddy P, Madhusudhan G (2012) Influence of grain refining elements on mechanical properties of AISI 430 ferritic stainless steel weldments—Taguchi approach[J]. Mater Des 36:443–450

Amuda MOH, Mridha S (2012) Comparative evaluation of grain refinement in AISI 430 FSS welds by elemental metal powder addition and cryogenic cooling[J]. Mater Des 35:609–618

Zhang H, Hu SS, Shen JQ, Ma L, Yin FL (2015) Microstructures and mechanical properties of 30Cr-4Mo ferritic stainless steel joints produced by double-pulsed gas metal arc welding. Int J Adv Manuf Technol 80:1975–1983

Tae JP, Jong PK, Sang HU, In SW, Jong SL, Chung YK (2011) Effect of Al–Si coating layer on the penetration and microstructures of ferritic stainless steel, 409L GTA welds[J]. J Mater Process Technol 211(3):415–423

Amuda MOH, Mridha S (2013) Grain refinement and hardness distribution in cryogenically cooled ferritic stainless steel welds[J]. Mater Des 47:365–371

Watanabe T, Nakamura H, Ei K (1989) Grain refinement by TIG welding with electromagnetic stirring—a study of solidification control of austenitic stainless steel weld metal[J]. Weld Int 3(4):312–317

Liu Z, Su M, Su Y (2009) Influence of magnetic field on microstructure and properties of stainless steel welding joint [J]. J Shenyang Univ Technol 6:014

Watanabe T, Shiroki M, Yanagisawa A, Sasaki T (2010) Improvement of mechanical properties of ferritic stainless steel weld metal by ultrasonic vibration[J]. J Mater Process Technol 210(12):1646–1651

Li DJ, Lu SP, Li DZ, Li YY (2010) Mechanisms increasing welding efficiency during new development of double shielded TIG process[J]. Sci Technol Weld Joining 15(6):528–533

Lakshminarayanan AK, Balasubramanian V (2010) An assessment of microstructure, hardness, tensile and impact strength of friction stir welded ferritic stainless steel joints[J]. Mater Des 31(10):4592–4600

Lakshminarayanan AK, Balasubramanian V (2012) Evaluation of microstructure and mechanical properties of laser beam welded AISI 409 M grade ferritic stainless steel[J]. J Iron Steel Res Int 19(1):72–78

Sprengard BA (2011) Effect of nitrogen concentration in shielding gas on microstructure and mechanical properties of ATI 2003® Lean Duplex Stainless Steel Autogenous Plasma Arc Welding[D]. University of Cincinnati

Keskitalo M, Mäntyjärvi K, Sundqvist J, Powell J, Kaplan AFH (2015) Laser welding of duplex stainless steel with nitrogen as shielding gas[J]. J Mater Process Technol 216:381–384

Pan DZ (2012) Physical simulation of variations in nitrogen content in laser welds of 21-6-9 austenitic stainless steel alloys. The Ohio State University

Villafuerte JC, Pardo E, Kerr HW (1990) The effect of alloy composition and welding conditions on columnar-equiaxed transitions in ferritic stainless steel gas-tungsten arc welds[J]. Metall Trans A 21(7):2009–2019

Villaret V, Deschaux-Beaume F, Bordreuil C, Rouquette S, Chovet C (2013) Influence of filler wire composition on weld microstructures of a 444 ferritic stainless steel grade[J]. J Mater Process Technol 213(9):1538–1547

Villafuerte JC, Kerr HW, David SA (1995) Mechanisms of equiaxed grain formation in ferritic stainless steel gas tungsten arc welds[J]. Mater Sci Eng A 194(2):187–191

Akhlaghi M, Steiner T, Meka SR, Leineweber A, Mittemeijer EJ (2015) Lattice-parameter change induced by accommodation of precipitate/matrix misfit; misfitting nitrides in ferrite[J]. Acta Mater 98:254–262

Sathiya P, Jaleel AMY (2011) Influence of shielding gas mixtures on bead profile and microstructural characteristics of super austenitic stainless steel weldments by laser welding. J Mater Process Technol 54:525–535

Lu S, Fujii H, Nogi K (2004) Marangoni convection and weld shape variations in Ar–O2 and Ar–CO2 shielded GTA welding[J]. Mater Sci Eng A 380(1):290–297

Li JY, Chen YL, Huo JH (2015) Mechanism of improvement on strength and toughness of H13 die steel by nitrogen[J]. Materials Science and Engineering: A

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, Y., Wang, Y., Li, H. et al. An experimental study of nitrogen gas influence on the 443 ferritic stainless steel joints by double-shielded welding. Int J Adv Manuf Technol 87, 3315–3323 (2016). https://doi.org/10.1007/s00170-016-8693-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8693-2