Abstract

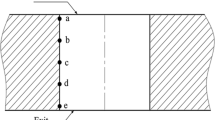

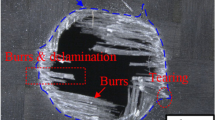

This paper demonstrates a novel method that combines X-ray computed tomography (CT) and image processing for investigating two materials with significantly different densities. CT is increasingly used in industrial applications of inspecting materials and defects. The limitations of the system and data reconstruction are continuously researched so as to improve the quality of the results. One of the most common issues in CT is beam hardening, frequently experienced in multi-material scanning. The materials examined to demonstrate the method are carbon fibre reinforced polymers (CFRP) and titanium alloy Ti6Al4V, often used in combination in industry to optimise the weight to strength ratio. The assembly of the materials is usually achieved by bolting and riveting, which requires drilling through the two materials together. The machining of these materials is difficult due to their higher specific properties and as a result tool wear is always an issue. CFRPs properties depend on the nature, orientation and bond of the fibres and as a result drilling affects their service life. The results of the method ensure the quality of the drilled holes by measuring the variation of the maximum diameter, circularity, positioning of the hole and an examining the entrance delamination and exit burrs by image processing.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Hsieh J (2009) Computed Tomography - Principles, design, artifacts, and recent advances, 2nd ed. SPIE Press, Washington

Herman GT (2009) Fundamentals of computed tomography - image reconstruction from projections. Springer, London

Kruth JP, Bartscher M, Carmignato S, Schmitt R, De Chiffre L, Weckenmann A (2011) Computed tomography for dimensional metrology. CIRP Ann 2011 - Manuf Technol 60:821–842

Sun W, Brown S, Leach RK (2012) An overview of industrial X-ray computed tomography. Queen’s Printer and Controller of HMSO, England

Kourra N, Warnett JM, Attridge A, Erchihan K, Gupta A, Barnes S, Williams MA (2015) Metrological study of CFRP drilled holes with x-ray computed tomography. Int J Adv Manuf Technol 78:2025–2035

Welkenhuyzen F, Kiekens K, Pierlet M, Dewulf W, Bleys P, Kruth JP, Voet A (2009) Industrial computer tomography for dimensional metrology: Overview of influence factors and improvement strategies. OPTIMESS Conference:2009

Kumar J, Attridge A, Wood PKC, Williams MA (2011) Analysis of the effect of cone-beam geometry and test object configuaration on the measurement accuracy of a computed tomography scanner used for dimensional measurement. Meas Sci Technol 22:35105–35120

Hiller J, Maisl M, Reindl LM (2012) Physical characterization and performance evaluation of an X-ray micro-computed tomography system for dimensional metrology applications. Meas Sci Technol 23:85404–85422

Weib D, Lonardoni R, Deffner A, Kuhn C (2012) Geometric image distortion in flat-panel X-ray detectos and its influence on the accuracy of CT-based dimensional measurements, iCT Conference Austria

Dewulf W, Kiekens K, Tan Y, Welkenhuyzen F, Kruth JP (2013) Uncertainty determination and quantification for dimensional measurements with industrial computed tomography. CIRP Ann - Manuf Technol 62:535–538

VDI/VDE (2010) Computed tomography in dimensional measurements. Measurement procedure and comparability VDI/VDE 2630 Part 1:4

Lifton JJ, Malcolm AA, McBride JW, Cross KJ (2013) The application of voxel size correction in X-ray Computed Tomography for dimensional metrology, Singapore International NDT Conference & Exhibition 2013

Teti R (2002) Machining of composite materials. CIRP Ann-Manuf Technol 51:611–634

Isbilir O, Ghassemieh E (2013) Comparative study of tool life and hole quality in drilling of CFRP/titanium stack using coated carbide drill. Mach Sci Technol 17:380–409

Ramulu M, Branson T, Kim D (2001) A study of the drilling of composite and titanium stacks. Compos Struct 53:67–77

Kim D, Ramulu M (2007) Study on the drilling of titanium/graphite hybrid composites. Trans of ASME 129:390–396

Grilo TJ, Paulo RMF, Silva CRM, Davim JP (2013) Experimental delamination analyses of CFRPs using different drill geometries. Compos: Part B 45:1344–1350

Persson E, Eriksson I, Zackrisson L (1997) Effects of hole machining defects on strength and fatigue life of composite laminates. Compos: Part A 28A:141–151

Abrate S, Walton DA (1992) Machining of composite materials Part I: traditional methods. Compos Manuf 3:75–83

Li Y, Zhou J, He Y, Hao X (2015) Drilling delamination and thermal damage of carbon nanotube/carbon fiber reinforced epoxy composites processed by microwave curing. Int J Mach Tool Manuf 97:11–17

Liu D, Tang Y, Cong W (2012) A review of mechanical drilling for composite laminates. Compos Struct 94:1265–1279

Davim JP, Reis P (2003) Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos Struct 59:481–487

Stone R, Krishnamurthy K (1996) A neural network thrust force controller to minimize delamination during drilling of graphite epoxy laminates. Int J Mach Tools Manuf 36:985–1003

Gaitonde VN, Karnik SR, Rubio JC, Correia AE, Abrao AM, Davim JP (2008) Analysis of parametric influence on delamination in high speed drilling of carbon fiber reinforced plastic composites. J Mater Process Technol 203:431–438

Abrao AM, Faria PE, Rubio JCC, Reis P, Davim JP (2007) Drilling of fiber reinforced plastics: a review. J Mater Process Technol 186:1–7

Marques AT, Durao LM, Magalhaes AG, Silva JF, Tavares JMR (2009) Delamination analysis of carbon fibre reinforced laminates: evaluation of a special step drill. Compos Sci Technol 69:2376–2382

Makhdum F, Norddin DNP, Roy A, Silberschmidt VV (2012) Ultrasonically assisted drilling of carbon fibre reinforced plastics. Solid State Phenom 188:170–175

Tsao CC, Hocheng H (2004) Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int J Mach Tools Manuf 44:1085–1090

Vob R, etal (2015) Evaluation of bore exit quality for fibre reinforced plastics including delamination and uncut fibres CIRP Journal of Manufacturing Science and Technology

Hocheng H, Tsao C (2003) Comprehensive analysis of delamination in drilling of composite materials with various drill bits. J Mater Process Technol 140:335–339

Boyle MM, Martin CJ, Neuner JD (2001) Epoxy resins, ASM handbook ohio: ASM international

Feldshtein E (2011) The influence of machining conditions on burr shapes when drilling reach-through holes in difficult to cut materials. Advances Manuf Sci Technol 35:75–83

Brinksmeier E, Janssen R (2002) Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. CIRP Ann - Manuf Technol 51:87–90

Dornfeld DA, Kim JS, Dechow H, Hewson J, Chen LJ (1999) Drilling burr formation in titanium alloy Ti6Al4V. Ann CIRP 48:73–76

Kim D, Ramulu M (2004) Drilling process optimization for graphite/bismaleimide-titanium alloy stacks. Compos Struct 63:101–114

Zhang PF, Churi NJ, Pei ZJ, Treadwell C (2008) Mechanical drilling processes for titanium alloys: a literature review. Mach Sci Technol 12:417–444

Makhdum F, Phadnis V, Roy A, Silberschmidt V (2014) Effect of ultrasonically-assisted drilling on carbon fibre reinforced plastics. J Sound Vib 333:5939–5952

Pujana J, Rivero A, Celaya A, Lopezz de Lacalle L (2014) Analysis of ultrasonic asssited drilling of Ti6Al4V. Int J Mach Tools Manuf 49:500–508

Phandis V, Makhdum F, Roy A, Silberschmidt V (2012) Experimental and numerical investigations in CFRP laminate, CIRP, 455–459

Dahnel AN, Ascroft H, Barnes S, Gloger M (2015) Analysis of tool wear and hole quality during ultrasonic assisted drilling of carbon fibre composite/titanium alloy (Ti6Al4V) stacks. texas, USA ASME International Mechanical Engineering Congress and Exposition

Goeje MP, Wapenaar KED (1992) Non-destructive inspection of carbon fibre-reinforced plastics using eddy current methods. Compos 23:147–157

Pye CJ, Adams RD (1981) Detection of damage in fibre reinforced plastics using thermal field generated during resonant vibration. NDT Int 14:111–118

Mook G, Lange R, Koeser O (2001) Non-destructive characterisation of carbon-fibre-reinforced plastics by means of eddy-currents. Compos Sci Technol 61:865–873

Mouritz AP, Townsend C, Shah Khan MZ (2000) Non-destructive detection of fatigue damage in thick composites by pulse-echo ultrasonics. Compos Sci Technol 60:23–32

Steinberger R, Valagas Leitao TI, Ladstatter E, Pinter G, Billinger W, Lang RW (2006) Infrared thermographic techniques for non-destructive damage characterization of carbon fibre reinforced polymers during tensile fatigue testing. Int J Fatigue 28:1340–1347

Seif MA, Khashaba UA, Rojas-Oviedo R (2007) Measuring delamination in carbon/epoxy composites using a shadow moire laser based imaging technique. Compos Struct 79:113–118

Raisutis R, Kazys R, Zukauskas E, Mazeika L, Vladisauskas A (2010) Application of ultrasonic guided waves for non-destructive testing of defective CFRP rods with multiple delaminations. NDT & E Int 43:416–424

Kourra N, Williams MA, Attridge A, Warnett J, Barnes S, Gupta A (2014) Analysis of drilled holes on carbon fibre material with X-ray Computed Tomography, IEEE International Workshop on Metrology for Aerospace 2014

Kachelrieb M, Soubelle K, Kalender WA (2006) Empirical cupping correction: a first-order raw data precorrection for cone-beam computed tomography. Med Phys 33:1269–1274

Silva D, Teixera JP, Machado CM (2014) Methodology analysis for evaluation of drilling-induced damage in composites. Int J Manuf Technol Manag 71:1919–1928

Krulikowski A (1997) Form Controls Fundamentals of Geometric Dimensioning & Tolerancing, vol 71-110. Effective Training Inc, Wayne

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kourra, N., Warnett, J.M., Attridge, A. et al. A metrological inspection method using micro-CT for the analysis of drilled holes in CFRP and titanium stacks. Int J Adv Manuf Technol 88, 1417–1427 (2017). https://doi.org/10.1007/s00170-016-8691-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8691-4