Abstract

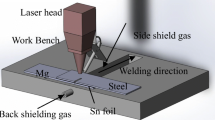

Magnesium alloy AZ31 was laser-welded to AlSi10Fe3-coated high-strength steel 22MnB5. The surface of the 22MnB5 steel sheet was treated by sandblasting before welding. Laser welding of magnesium with steel was found to be a welding-brazing process, due to the large difference in the melting temperatures of steel and magnesium. The liquid magnesium was wetted on the solid steel surface, which thus was a brazing process on the steel side. AZ61 magnesium welding filler was used to improve adhesion of the liquid magnesium to the steel surface. Furthermore, the suitability of using a flux was determined. Welded steel/magnesium joints with a high tensile strength of 2680–3090 N (178–213 MPa) were produced using a flux and inductive preheating of the conditioned steel surface. Under tensile loading, the welded joints did not fail at the steel/magnesium interface, but in the AZ61 magnesium welding filler. Metallurgical bonding at the magnesium/steel interface was attributed to the formation of a thin Al-Fe-rich layer, which is due to the alloyed aluminum (6 mass%) in the magnesium welding filler.

Similar content being viewed by others

References

Braess HH, Seiffert U (2013) Vieweg Handbuch Kraftfahrzeugtechnik. Springer Vieweg Verlag, 7th Edition

Dauensteiner A (2002) Der Weg zum Ein-Liter-Auto. Springer Verlag, Berlin

Karbasian H, Tekkaya AE (2010) A review on hot stamping. J Mater Process Technol 210:2103–2118

Massalki TB (1996) Binary alloy phase diagrams. ASM

Chen YC, Nakata K (2009) Effect of tool geometry on microstructure and mechanical properties of friction stir lap welded magnesium alloy and steel. Mater Des 30:3913–3919

Jana S, Hovanski Y, Grant GJ (2010) Friction stir lap welding of magnesium alloy to steel: a preliminary investigation. Metall Mater Trans 41A:3173–3182

Liu L, Xiao L, Feng JC, Tian YH, Zhou SQ, Zhou Y (2010) The mechanisms of resistance spot welding of magnesium to steel. Metall Mater Trans 41A:2651–2661

Wei Y, Li J, Xiong J, Huang F, Zhang F (2012) Microstructures and mechanical properties of magnesium alloy and stainless steel weld-joint made by friction stir lap welding. Mater Des 33:111–114

Liu LM, Zhao X (2008) Study on the weld joint of Mg alloy and steel by laser-GTA hybrid welding. Mater Charact 59:1279–1284

Qi X, Song G (2010) Interfacial structure of the joints between magnesium alloy and mild steel with nickel as interlayer by hybrid laser-TIG welding. Mater Des 31:605–609

Liqun L, Caiwang T, Yanbin C, Wei G, Changxing M (2013) CO2 laser welding–brazing characteristics of dissimilar metals AZ31B Mg alloy to Zn coated dual phase steel with Mg based filler. J Mater Process Technol 213:361–375

Li L, Tan C, Chen Y, Guo W, Mei C, Hu X (2012) Influence of Zn coating on interfacial reactions and mechanical properties during laser welding-brazing of Mg to steel. Metall Mater Trans 43A:4740–4754

Tan C, Li L, Chen Y, Guo W (2013) Laser-tungsten inert gas hybrid welding of dissimilar metals AZ31B Mg alloys to Zn coated steel. Mater Des 49:766–773

Wahba M, Katayama S (2012) Laser welding of AZ31B magnesium alloy to Zn-coated steel. Mater Des 35:701–706

Windmann M, Röttger A, Theisen W (2013) Phase formation at the interface between a boron alloyed steel substrate and an Al-rich coating. Surf Coat Technol 226:130–139

Windmann M, Röttger A, Kügler H, Theisen W, Vollertsen F (2015) Laser beam welding of aluminum to Al-base coated high-strength steel 22MnB5. J Mater Process Technol 217:88–95

Kubošová A, Karlík M, Haušild P, Prahl J (2008) Fracture behaviour of Fe3Al and FeAl type iron aluminides. Mater Sci Forum 567–568:349–352

Windmann M, Röttger A, Kügler H, Theisen W (2016) Removal of oxides and brittle coating constituents at the surface of coated hot-forming 22MnB5 steel for a laser welding process with aluminum alloys. Surf Coat Technol 285:153–160

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Windmann, M., Röttger, A., Kügler, H. et al. Laser beam welding of magnesium to coated high-strength steel 22MnB5. Int J Adv Manuf Technol 87, 3149–3156 (2016). https://doi.org/10.1007/s00170-016-8682-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8682-5