Abstract

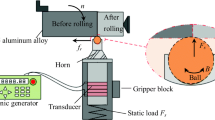

Ultrasonic surface rolling process (USRP) is an effective method to improve material surface quality, such as surface finish, microstructure, and stress state. Previously, USRP is usually used in comparably hard materials (e.g., instance steel and titanium alloys). In this paper, attention is focused on low hardness aluminum alloy which is widely used in the aviation industry. Aluminum alloy 7050-T7451 is used to investigate its surface characteristics in the ultrasonic rolling experiment. With the aid of surface optical profiler, X-ray stress analyzer, scanning electronic microscope (SEM), and energy-dispersive spectrometer (EDS), the differences of surface characteristics are explored in the USRP-treated area and that of the turning area. In addition, the influence of feed rate on surface integrity is also investigated. The results show that surface integrity is improved by USRP, and the best quality is obtained with the feed speed of 0.10 mm/r. Under the optimal experimental condition, surface roughness (R a ) is reduced to 0.059 μm, axial and tangential surface compressive residual stress is increased to −130.6 and −330.8 MPa, respectively, and surface microhardness is increased by 41.3 %. Metal flow traces, fusion of surface grain boundary, and the phenomenon of impurity phase diffusion are observed in the cross section of the treated specimen. The internal strengthening mechanism of the USRP-treated surface is probed.

Similar content being viewed by others

References

Zhuang W, Liu Q, Djugum R, Sharp PK, Paradowska A (2014) Deep surface rolling for fatigue life enhancement of laser clad aircraft aluminium alloy. Appl Surf Sci 320:558–562. doi:10.1016/j.apsusc.2014.09.139

Bouzid W, Tsoumarev O, Sa K (2003) An investigation of surface roughness of burnished AISI 1042 steel. Int J Adv Manuf Technol 24:120–125. doi:10.1007/s00170-003-1761-4

Mohammadi F, Sedaghati R, Bonakdar A (2014) Finite element analysis and design optimization of low plasticity burnishing process. Int J Adv Manuf Technol 70:1337–1354. doi:10.1007/s00170-013-5406-y

Roland T, Retraint D, Lu K, Lu J (2006) Fatigue life improvement through surface nanostructuring of stainless steel by means of surface mechanical attrition treatment. Scr Mater 54:1949–1954. doi:10.1016/j.scriptamat.2006.01.049

Bozdana AT, Gindy NNZ, Li H (2005) Deep cold rolling with ultrasonic vibrations—a new mechanical surface enhancement technique. Int J Mach Tool Manuf 45:713–718. doi:10.1016/j.ijmachtools.2004.09.017

Cheng M, Zhang D, Chen H, Qin W (2014) Development of ultrasonic thread root rolling technology for prolonging the fatigue performance of high strength thread. J Mater Process Technol 214:2395–2401. doi:10.1016/j.jmatprotec.2014.05.019

Wang T, Wang D, Liu G, Gong B, Song N (2008) Investigations on the nanocrystallization of 40Cr using ultrasonic surface rolling processing. Appl Surf Sci 255:1824–1829. doi:10.1016/j.apsusc.2008.06.034

Wang T, Wang D, Liu G, Gong B, Song N (2009) 40Cr Nano-crystallization by ultrasonic surface rolling extrusion processing. J Mech Eng 45:177–183. doi:10.3901/JME.2009.05.177

Liu Y, Wang L, Wang D (2011) Finite element modeling of ultrasonic surface rolling process. J Mater Process Technol 211:2106–2113. doi:10.1016/j.jmatprotec.2011.07.009

Liu Y, Zhao X, Wang D (2014) Determination of the plastic properties of materials treated by ultrasonic surface rolling process through instrumented indentation. Mater Sci Eng A 600:21–31. doi:10.1016/j.msea.2014.01.096

Xie J, Zhu Y, Huang Y, Bai C, Ye X (2013) Microstructure characteristics of 30CrMnSiNi2A steel after ultrasound-aided deep rolling. J Mater Eng Perform 22:1642–1648. doi:10.1007/s11665-012-0459-x

Zhao X, Fan Y, Wang H, Liu Y (2015) Revealing the surface nano-enhancing mechanism of α-titanium alloy by microstructure evolution. Mater Lett 160:51–54. doi:10.1016/j.matlet.2015.07.067

Pyun YS, Cho IH, Suh CM, Park J, Rogers J, Kayumov R, Murakami R (2013) Reducing production loss by prolonging service life of rolling mill shear pin with ultrasonic nanocrystal surface modification technology. Int J Precis Eng Manuf 14:2027–2032. doi:10.1007/s12541-013-0276-7

Zhu Y, Wang K, Li L, Huang Y (2009) Evaluation of an ultrasound-aided deep rolling process for anti-fatigue applications. J Mater Eng Perform 18:1036–1040. doi:10.1007/s11665-008-9341-2

She D, Yue W, Du Y, Fu Z, Wang C, Liu J (2015) Vacuum tribological properties of titanium with a nanocrystalline surface layer. Tribol Lett. 57. doi: 10.1007/s11249-014-0447-4

Huang X, Sun J, Li J (2015) Finite element simulation and experimental investigation on the residual stress-related monolithic component deformation. Int J Adv Manuf Technol 77:1035–1041. doi:10.1007/s00170-014-6533-9

Rasooli M, Moshref-javadi M, Taherizadeh A (2015) Investigation of ultrasonic vibration effects on the microstructure and hardness of aluminum alloy 2024 tube spinning parts. Int J Adv Manuf Technol 77:2117–2124. doi:10.1007/s00170-014-6500-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, L.X., Sun, J., Li, L. et al. Study on surface characteristics of 7050-T7451 aluminum alloy by ultrasonic surface rolling process. Int J Adv Manuf Technol 87, 2533–2539 (2016). https://doi.org/10.1007/s00170-016-8659-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8659-4