Abstract

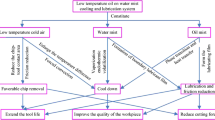

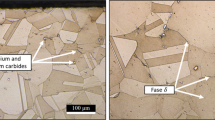

The elimination of cutting fluids’ usage is one of the great challenges of sustainable manufacturing. Various devices and alternative techniques have been developed, but their results are limited, as well as their commercial applications. Most of them require drastic changes in the cutting tools or machine tools, or operate with nonevaporative cooling cycles, with low cooling capacity. The aim of this study is to present a device that overcomes these limitations and stands as an alternative to the application of cutting fluid without sacrificing the performance of the machining. Thus, a toolholder is developed that enables the indirect cooling of the cutting tool with a pumped two-phase system using the coolant R141b (vaporization temperature of 32 °C). In this system, the geometry of the cutting tool is not changed and there is no direct contact with the refrigerant, so there is no contamination or piece cleaning necessity. Moreover, the system operates in a closed circuit with only 5 l of coolant that does not require constant treatment. The performance of the proposed method of internal cooling is evaluated by turning tests of AISI 1045 steel under conditions of continuous and interrupted cut. The turning tests compare the lives of the uncoated cemented carbide cutting tools, their temperatures, and wear mechanisms acting during machining with the internal cooling method, or cutting fluid or dry cutting. The results show that the internal cooling is able to extend the life of cutting tools by 58 % in interrupted cutting and by 7 % in continuous cutting in relation to the cutting fluid application and by 13 and by 45 % in relation to the interrupted and continuous dry cutting, respectively. The thermal analysis indicates that the internal cooling method reduces the average surface temperature of the contact zone by 10 % when compared to dry cutting. This device has a great possibility of use by the industry because is an effective and environmentally friendly technology.

Similar content being viewed by others

References

Bruni C, Forcellese A, Gabrielli F, Simoncini M (2006) Effect of the lubrication-cooling technique, insert technology and machine bed material on the workpiece surface finish and tool wear in finish turning of AISI 420B. Int J Mach Tool Manuf 46(12–13):1547–1554

Klocke F, EIsenblätter G (1997) Dry cutting. Ann CIRP 46:519–527

Wichmann H, Stache H, Schmidt C, Winter M, Bock R, Herrmann C, Bahadir M (2013) Ecological and economic evaluation of a novel glycerol based biocide-free metalworking fluid. J Clean Prod 43:12–19

Zhao F, Ogaldez J, Sutherland JW (2012) Quantifying the water inventory of machining processes. CIRP Ann Manuf Technol 61:67–70

Burton CM, Crook B, Scaife H, Evans GS, Barber CM (2012) Systematic review of respiratory outbreaks associated with exposure to water-based metalworking fluids. Ann Occup Hyg 56(4):374–388

De Groot A, Geier J, Flyvholm M, Lensen G, Coenraads P (2010) Formaldehyde-releasers: relationship to formaldehyde contact allergy. Metalworking fluids and remainder. Part 1. Contact Dermatitis 63:117–128

Suuronen K, Aalto-Korte K, Piipari R, Tuomi T, Jolanki R (2007) Occupational dermatitis and allergic respiratory diseases in Finnish metalworking machinists. Occup Med 57:227–283

Trafny EA (2013) Microorganisms in metalworking fluids: current issues in research and management. Int J Occup Med Environ Health 26(1):4–15

Dudzinski D, Devillez A, Moufki A, Larrouquere D, Zerrouki V, Vigneau J (2004) A review of developments towards dry and high speed machining of Inconel 718 alloy. Int J Mach Tool Manuf 44:439–456

Jianxin D, Hui Z, Ze W, Yunsong L, Jun Z (2012) Friction and wear behaviors of WC/Co cemented carbide tool materials with different WC grain sizes at temperatures up to 600 °C. Int J Refract Met Hard Mater 31:196–204

Schaller E (1965) Einfluss der diffusion auf den Verschleiss von Hartmetallwerkzeugen bei der Zerspanung von Stahl. Ind Anz 87(9):9–14

Shaw MC (2005) Metal cutting principles, 2nd edn. Oxford University Press, New York, 594 p

Yildiz Y, Nalbant M (2008) A review of cryogenic cooling in machining processes. Int J Mach Tool Manuf 48(9):947–964

Dhar NR, Kamruzzaman M, Khan MMA, Chattopadhyay AB (2006) Effects of cryogenic cooling by liquid nitrogen jets on tool wear, surface finish and dimensional deviation in turning different steels. Int J Mach Mach Mater 1(1):115–135

Çakir O, Kiyak M, Altan E (2004) Comparison of gases applications to wet and dry cuttings in turning. J Mater Process Technol 35–41:153–154

Ahmed MI, Ismail AF, Nurul AKM (2007) Effectiveness of cryogenic machining with modified toolholder. J Mater Process Technol 185:91–96

Bouzakis K, Michailidis N, Skordaris G, Bouzakis E, Biermann D, M'saoubi R (2012) Cutting with coated tools: coating technologies, characterization methods and performance optimization. CIRP Ann Manuf Technol 61:703–723

Weinert K, InasakI I, Sutherland JW, Wakabayashi T (2004) Dry machining and minimum quantity lubrication. CIRP Ann Manuf Technol 53:511–537

Jeffries NP (1969) A new cooling method for metal-cutting tools, Ph.D. Dissertation, University of Cincinnati

Jeffries NP, Zerkle RD (1970) Thermal analysis of an internally-cooled metal-cutting tool. Int J Mach Tool Manuf 10:381–399

Zhao H, Barber GC, Zou Q (2002) A study of flank wear in orthogonal cutting with internal cooling. Wear 253:957–962

Zhao H, Barber GC, Zou Q, Gu R (2006) Effect of internal cooling on tool-chip interface temperature in orthogonal cutting. Tribol Trans 49:125–134

Chiou RY, Lu L, Chen JS, North MT (2007) Investigation of dry machining with embedded heat pipe cooling by finite element analysis and experiments. Int J Adv Manuf Technol 31:905–914

Al-Odat MQ (2010) Numerical analysis of cutting tool temperature in dry machining processes with embedded heat pipe. Eng Comput 27:658–673

Liang L, Quan Y, Ke Z (2011) Investigation of tool-chip interface temperature in dry turning assisted by heat pipe cooling. Int J Adv Manuf Technol 54:35–43

Rozzi JC, Sanders JK, Chen W (2011) The experimental and theoretical evaluation of an indirect cooling system for machining. J Heat Transf 133(3):10p

Ferri C, Minton T, Ghani SBC, Cheng K (2013) Internally-cooled tools and cutting temperature in contamination-free machining. Proc Inst Mech Eng Part C J Mech Eng Sci 1–11

Sun X, Bateman R, Cheng K, Ghani SC (2001) Design and analysis of an internally-cooled smart cutting tool for dry cutting. Proc Inst Mech Eng B J Eng Manuf 226:585–591

Minton T, Ghani S, Sammler F, Bateman R, Fürstmann P, Roeder M (2013) Temperature of internally-cooled diamond-coated tools for dry-cutting titanium. Int J Mach Tool Manuf 75:27–35

Sanchez LEA, Scalon VL, Abreu GGC (2011) Cleaner machining through a toolholder with internal cooling. 3rd International Workshop Advances in Cleaner Production, São Paulo

Vicentin GC, Sanchez LEA, Scalon VL, Abreu GGC (2011) A sustainable alternative for cooling the machining processes using a refrigerant fluid in recirculation inside the toolholder. Clean Techn Environ Policy 13:831–840

Bhatia SM, Pandey PC, Shan HS (1978) Thermal cracking of carbide tools during intermittent cutting. Wear 51:201–211

Molés F, Navarro-Esbrí J, Peris B, Mota-Babilone A, Kontomaris K (2015) Thermodynamic analysis of a combined organic Rankine cycle and vapor compression cycle system activated with low temperature heat sources using low GWP fluids. Appl Therm Eng 87:444–453

Komanduri R, Hou ZB (2000) Thermal modeling of the metal cutting process part I—temperature rise distribution due to shear plane heat source. Int J Mech Sci 42:1715–1752

Komanduri R, Hou ZB (2001) Thermal modeling of the metal cutting process part II—temperature rise distribution due to frictional heat source at the tool-chip interface. Int J Mech Sci 43:57–88

Komanduri R, Hou ZB (2001) Thermal modeling of the metal cutting process part III—temperature rise distribution due to the combined effects of shear plane heat source and the tool-chip interface frictional heat source. Int J Mech Sci 43:89–107

Lienhard JH, Eichhorn R (1976) Peak boiling heat flux on cylinders in a cross flow. Int J Heat Mass Transf 19:1135–1142

Wang ZY, Rajurkar KP, Fan J, Lei S, Shin YC, Petrescu G (2003) Hybrid machining of Inconel 718. Int J Mach Tool Manuf 43:1391–1396

Dandekar CR, Shin YC, Barnes J (2010) Machinability improvement of titanium alloy (Ti–6Al–4V) via LAM and hybrid machining. Int J Mach Tool Manuf 50:174–182

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ingraci Neto, R.R., Scalon, V.L., Fiocchi, A.A. et al. Indirect cooling of the cutting tool with a pumped two-phase system in turning of AISI 1045 steel. Int J Adv Manuf Technol 87, 2485–2495 (2016). https://doi.org/10.1007/s00170-016-8620-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8620-6