Abstract

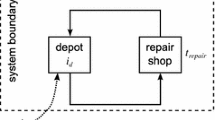

The process of remanufacturing is attractive economically and environmentally for both manufacturers and customers. This paper addresses a problem in the repairable spare parts remanufacturing industry to find the cost-optimal production strategy incorporating reconditioned components. New and reconditioned components are used to carry out replacements in order to honor warranty commitments. Key production decisions, such as when remanufacturing should commence, how long the warranty period should be, and how many returned components should be reconditioned are considered. The availability of reconditioned components and their discounted costs are also incorporated in the mathematical model. The goal is to investigate the interaction between these decisions and their impacts on the manufacturing system and the customer. An application to the remanufacturing of rotable spare parts in the airline industry is presented.

Similar content being viewed by others

References

Bitran GR, Hax AC (1977) On the design of hierarchical production planning systems. Decis Sci 8(1):28–55

Boucekkine R, Saglam C, Vallée T (2004) Technology adoption under embodiment: a two-stage optimal control approach. Macroecon Dyn 8(02):250–271

Bourgeois H, Leleux B (2004) Renault trucks: remanufacturing as a strategic activity. Tech. rep., International Institute for Management Development, Lausanne, Switzerland

Chari N (2015) Thematic development of recovery, remanufacturing, and support models for sustainable supply chains. Ph.D. thesis, Dalhousie University, Halifax, Canada

Chari N, Diallo C, Venkatadri U (2013) Optimal unlimited free-replacement warranty strategy using reconditioned products. International Journal of Performability Engineering 9(2):191–200

Chari N, Diallo C, Venkatadri U (2014) State of the art on performability across the sustainable value chain. International Journal of Performability Engineering 10(6):543–556

Duffuaa SO, Andijani AA (1999) An integrated simulation model for effective planning of maintenance operations for Saudi Arabian airlines (SAUDIA). Production Planning Control 10(6):579–584

Friend CH, Ghobbar AA (1996) Aircraft maintenance and inventory control: using the material requirements planning system-can it reduce costs and increase efficiency?. In: SAE Airframe Finishing Maintenance and Repair Conference and Exposition. Jacksonville, USA

Ghobbar AA, Friend CH (2002) Sources of intermittent demand for aircraft spare parts within airline operations. Journal of Air Transport Management 8(4):221–231

Graves SC (1981) A review of production scheduling. Oper Res 29(4):646–675

Graves SC (1999) Manufacturing planning and control. Massachusetts Institute of Technology:1–26

Guide Jr. VDR (2000) Production planning and control for remanufacturing: industry practice and research needs. J Oper Manag 18(4):467–483

Gutowski TG, Sahni S, Boustani A, Graves SC (2011) Remanufacturing and energy savings. Environ Sci Technol 45(10):4540–4547

Hax AC, Meal HC (1973) Hierarchical integration of production planning and scheduling. Tech. rep., DTIC Document

Huang HZ, Liu ZJ, Murthy DNP (2007) Optimal reliability, warranty and price for new products. IIE Trans 39(8):819–827

Kim B, Park S (2008) Optimal pricing, EOL (end of life) warranty, and spare parts manufacturing strategy amid product transition. Eur J Oper Res 188(3):723–745

Lund RT, Hauser W (2003) The Remanufacturing Industry: Anatomy of a Giant. Boston University, Boston USA

Makris M (2001) Necessary conditions for infinite-horizon discounted two-stage optimal control problems. J Econ Dyn Control 25(12):1935–1950

Mamer JW (1987) Discounted and per unit costs of product warranty. Manag Sci 33(7):916–930

Mangasarian OL (1966) Sufficient conditions for the optimal control of nonlinear systems. SIAM J Control 4(1):139–152

Moore JM, Wilson RC (1967) A review of simulation research in job shop scheduling. Prod Invent Manag 8(1):1–10

Murthy DNP, Djamaludin I (2002) New product warranty: a literature review. Int J Prod Econ 79(3):231–260

Regattieri A, Gamberi M, Gamberini R, Manzini R (2005) Managing lumpy demand for aircraft spare parts. Journal of Air Transport Management 11(6):426–431

Rossana RJ (1985) Delivery lags and buffer stocks in the theory of investment by the firm. J Econ Dyn Control 9(2):153–193

Silver EA (2008) Inventory management: an overview, Canadian publications, practical applications and suggestions for future research. INFOR 46(1):15–28

Simao H, Powell W (2009) Approximate dynamic programming for management of high-value spare parts. J Manuf Technol Manag 20(2):147–160

Thierry MC, Salomon M, van Nunen J. AEE, Van Wassenhove LN (1995) Strategic issues in product recovery management. Calif Manage Rev 37(2):114–135

Tomiyama K (1985) Two-stage optimal control problems and optimality conditions. J Econ Dyn Control 9 (3):317–337

Tomiyama K, Rossana RJ (1989) Two-stage optimal control problems with an explicit switch point dependence: optimality criteria and an example of delivery lags and investment. J Econ Dyn Control 13(3):319–337

Walsh B, Waugh R, Symington H Remanufacturing study—circular economy evidence building programme—summary report. Tech. rep., Zero Waste Scotland, Stirling, UK

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chari, N., Diallo, C., Venkatadri, U. et al. Production planning in the presence of remanufactured spare components: an application in the airline industry. Int J Adv Manuf Technol 87, 957–968 (2016). https://doi.org/10.1007/s00170-016-8520-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8520-9