Abstract

The milling process is a widely used conventional machining operation. Due to economic reasons, the multi-pass milling process is more convenient. However, the required time for machining increases and an optimization solution must be undertaken. In this paper, the total production time is minimized by resorting to a powerful bio-inspired algorithm, called the cuckoo optimization algorithm. The constraints are successfully handled and the optimal results are compared with those available in the literature. It is shown that the present results are better.

Similar content being viewed by others

References

R. Venkata Rao. (2010) Modeling and optimization of machining processes. In Advanced modeling and optimization of manufacturing processes. UK: Springer London, 2010, ch. 2, pp. 55–175

Sonmez AI, Baykasoglu A, Dereli T, Filiz IH (1999) Dynamic optimization of multipass milling operations via geometric programming. Int J Mach Tools Manuf 39(2):297–320

Wang ZG, Rahman M, Wong YS, Sun J (2005) Optimization of multi-pass milling using parallel genetic algorithm and parallel genetic simulated annealing. Int J Mach Tools Manuf 45(15):1726–1734

Onwubolu GC (2006) Performance-based optimization of multi-pass face milling operations using Tribes. Int J Mach Tools Manuf 56(7–8):717–727

Gao L, Huang J, Li X (2012) An effective cellular particle swarm optimization for parameters optimization of a multi-pass milling process. Appl Soft Comput 12(11):3490–3499

Venkata Rao R, Pawar PJ (2010) Parameter optimization of a multi-pass milling process using non-traditional optimization algorithms. Appl Soft Comput 10(2):445–456

Yang Y, Li X, Gao L (2013) Parameters optimization of a multi-pass milling process based on imperialist competitive algorithm. In 2013 I.E. 17th International Conference on Computer Supported Cooperative Work in Design, Whistler, Canada, 2013, pp. 406–410

Pawar PJ, Venkata Rao R (2013) Parameter optimization of machining processes using teaching–learning-based optimization algorithm. Int J Adv Manuf Technol 67(5):995–1006

Huang J, Gao L, Li X (2015) An effective teaching-learning-based cuckoo search algorithm for parameter optimization problems in structure designing and machining processes. Appl Soft Comput 36:349–356

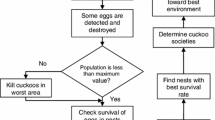

Rajabioun R (2011) Cuckoo optimization algorithm. Appl Soft Comput 11(8):5508–5518

Rabiee M, Sajedi H (2013) Job scheduling in grid computing with cuckoo optimization algorithm. Int J Comput Appl 62(16):38–44

Mellal MA, Williams EJ (2014) Parameter optimization of advanced machining processes using cuckoo optimization algorithm and hoopoe heuristic. J Intell Manuf. doi:10.1007/s10845-014-0925-4

Mellal MA, Williams EJ (2015) Cuckoo optimization algorithm for unit production cost in multi-pass turning operations. Int J Adv Manuf Technol 76(1):647–656

Roozitalab A, Asgharizadeh E (2013) Optimizing the warranty period by cuckoo meta-heuristic algorithm in heterogeneous customers’ population. J Ind Eng Int 9(27):1–6

Mellal MA, Adjerid S, Williams EJ, Benazzouz D (2012) Optimal replacement policy for obsolete components using cuckoo optimization algorithm based-approach: Dependability context. J Sci Ind Res 71(11):715–721

Mellal MA, Adjerid S, Williams EJ (2013) Optimal selection of obsolete tools in manufacturing systems using cuckoo optimization algorithm. Chem Eng Trans 33:355–360

Addeh J, Ebrahimzadeh A, Azarbad M, Ranaee V (2014) Statistical process control using optimized neural networks: a case study. ISA Trans 53(5):1489–1499

Mellal MA, Williams EJ (2015) Cuckoo optimization algorithm with penalty function for combined heat and power economic dispatch problem. Energy 93:1711–1718

Smith AE, Coit DW (1997) Constraint handling techniques–penalty functions. In Handbook of Evolutionary Computation.: Oxford University Press and Institute of Physics Publishing, ch. 5.2-1–5.2-6

Mezura-Montes E, Coello Coello CA (2011) Constraint-handling in nature-inspired numerical optimization: past, present and future. Swarm and Evol Comput 1(4):173–194

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mellal, M.A., Williams, E.J. Total production time minimization of a multi-pass milling process via cuckoo optimization algorithm. Int J Adv Manuf Technol 87, 747–754 (2016). https://doi.org/10.1007/s00170-016-8498-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8498-3