Abstract

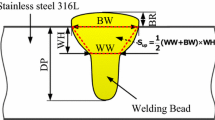

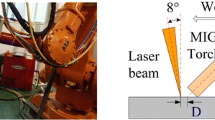

Laser brazing (LB) provides a promising way to join the galvanized steels in automotive industry. The process parameters of LB have significant effects on the bead profile and hence the quality of joint. Since the relationships between the process parameters and bead profiles cannot be expressed explicitly, it is impractical to determine the optimal process parameters intuitively. This paper proposes an optimization methodology by combining Kriging surrogate and particle swarm optimization (PSO) to address the process parameters optimization of the bead profiles in LB with crimping butt of 0.8-mm-thick galvanized steel. Firstly, an experiment using Taguchi L 25 orthogonal array is conducted where welding speed (WS), wire speed rate (WF), and gap (GAP) are taken into consideration as the input parameters, while the bead profiles are the output responses. Secondly, the relationships between the inputs and outputs are established using the Kriging model. Thirdly, the effects of the input parameters on the bead profiles are analyzed, and the global process parameters are obtained by the presented Kriging-PSO approach. At last, the verification experiments were conducted to verify the effectiveness of the optimal values. On the whole, the proposed hybrid method, Kriging-PSO, shows great promise for improving the effectiveness and stability of LB welding process.

Similar content being viewed by others

References

Zhang Y, Gao X (2013) Analysis of characteristics of molten pool using cast shadow during high-power disk laser welding. Int J Adv Manuf Technol 70(9-12):1979–1988. doi:10.1007/s00170-013-5442-7

Chen H-C, Pinkerton AJ, Li L, Liu Z, Mistry AT (2011) Gap-free fibre laser welding of Zn-coated steel on Al alloy for light-weight automotive applications. Mater Des 32(2):495–504. doi:10.1016/j.matdes.2010.08.034

Qin G, Lei Z, Su Y, Fu B, Meng X, Lin S (2014) Large spot laser assisted GMA brazing–fusion welding of aluminum alloy to galvanized steel. J Mater Process Technol 214(11):2684–2692. doi:10.1016/j.jmatprotec.2014.06.011

Colombo D, Previtali B (2014) Laser dimpling and remote welding of zinc-coated steels for automotive applications. Int J Adv Manuf Technol 72(5-8):653–663. doi:10.1007/s00170-014-5690-1

Quintino L, Pimenta G, Iordachescu D, Miranda RM, Pepe NV (2006) MIG brazing of galvanized thin sheet joints for automotive industry. Mater Manuf Process 21(1):63–73. doi:10.1081/Amp-200060621

Zhao Y, Zhang Y, Hu W, Lai X (2012) Optimization of laser welding thin-gage galvanized steel via response surface methodology. Opt Lasers Eng 50(9):1267–1273. doi:10.1016/j.optlaseng.2012.03.010

Shah LH, Ishak M (2014) Review of research progress on aluminum-steel dissimilar welding. Mater Manuf Process 29(8):928–933, doi:10.1080/10426914.2014.880461

Cao X, Wallace W, Poon C, Immarigeon JP (2003) Research and progress in laser welding of wrought aluminum alloys. I Laser welding processes. Mater Manuf Processes 18(1):1–22. doi:10.1081/Amp-120017586

Chen W, Ackerson P, Molian P (2009) CO2 laser welding of galvanized steel sheets using vent holes. Mater Des 30(2):245–251. doi:10.1016/j.matdes.2008.05.009

Iqbal S, Gualini MMS, Rehman A (2010) Dual beam method for laser welding of galvanized steel: experimentation and prospects. Opt Laser Technol 42(1):93–98. doi:10.1016/j.optlastec.2009.05.009

Qin GL, Su YH, Meng XM, Fu BL (2015) Numerical simulation on MIG arc brazing-fusion welding of aluminum alloy to galvanized steel plate. Int J Adv Manuf Tech 78(9-12):1917–1925. doi:10.1007/s00170-014-6529-5

Rong YM, Zhang Z, Zhang GJ, Yue C, Gu YF, Huang Y, Wang CM, Shao XY (2015) Parameters optimization of laser brazing in crimping butt using Taguchi and BPNN-GA. Opt Lasers Eng 67:94–104. doi:10.1016/j.optlaseng.2014.10.009

Ma K, Yu ZS, Zhang PL, Lu YL, Yan H, Li CG, Liu XP (2015) Influence of wire feeding speed on laser brazing zinc-coated steel with Cu-based filler metal. Int J Adv Manuf Tech 76(5-8):1333–1342. doi:10.1007/s00170-014-6347-9

Joo S-M, Bang H-S, Kwak S-Y (2014) Optimization of hybrid CO2 laser-GMA welding parameters on dissimilar materials AH32/STS304L using grey-based Taguchi analysis. Int J Precis Eng Manuf 15(3):447–454. doi:10.1007/s12541-014-0356-3

Singh A, Cooper DE, Blundell NJ, Pratihar DK, Gibbons GJ (2013) Modelling of weld-bead geometry and hardness profile in laser welding of plain carbon steel using neural networks and genetic algorithms. Int J Comput Integr Manuf 27(7):656–674. doi:10.1080/0951192x.2013.834469

Benyounis KY, Olabi AG, Hashmi MSJ (2005) Optimizing the laser-welded butt joints of medium carbon steel using RSM. J Mater Process Technol 164–165:986–989. doi:10.1016/j.jmatprotec.2005.02.067

Ruggiero A, Tricarico L, Olabi AG, Benyounis KY (2011) Weld-bead profile and costs optimisation of the CO2 dissimilar laser welding process of low carbon steel and austenitic steel AISI316. Opt Laser Technol 43(1):82–90. doi:10.1016/j.optlastec.2010.05.008

Katherasan D, Elias JV, Sathiya P, Haq AN (2012) Simulation and parameter optimization of flux cored arc welding using artificial neural network and particle swarm optimization algorithm. J Intell Manuf 25(1):67–76. doi:10.1007/s10845-012-0675-0

Acar E (2015) Effect of error metrics on optimum weight factor selection for ensemble of metamodels. Expert Syst Appl 42(5):2703–2709. doi:10.1016/j.eswa.2014.11.020

Vafeiadis T, Diamantaras KI, Sarigiannidis G, Chatzisavvas KC (2015) A comparison of machine learning techniques for customer churn prediction. Simul Model Pract Th 55:1–9. doi:10.1016/j.simpat.2015.03.003

Jiang P, Wang JZ, Zhou Q, Zhang XL (2015) An Enhanced Analytical Target Cascading and Kriging Model Combined Approach for Multidisciplinary Design Optimization. Math Probl Eng. doi:10.1155/2015/685958

Li X, Lawson S, Zhou Y, Goodwin F (2007) Novel technique for laser lap welding of zinc coated sheet steels. J Laser Appl 19(4):259. doi:10.2351/1.2795755

Zhang HT, Feng JC, He P, Hackl H (2007) Interfacial microstructure and mechanical properties of aluminium–zinc-coated steel joints made by a modified metal inert gas welding–brazing process. Mater Charact 58(7):588–592. doi:10.1016/j.matchar.2006.07.008

Schmidt M, Otto A, Kägeler C (2008) Analysis of YAG laser lap-welding of zinc coated steel sheets. CIRP Ann Manuf Technol 57(1):213–216. doi:10.1016/j.cirp.2008.03.043

Zadeh PM, Toropov VV, Wood AS (2009) Metamodel-based collaborative optimization framework. Struct Multidiscip O 38(2):103–115. doi:10.1007/s00158-008-0286-8

Cui L, He DY, Guo F, Li XY, Jiang JM (2010) Effect of fiber laser-MIG hybrid process parameters on weld bead shape and tensile properties of commercially pure titanium. Mater Manuf Process 25(11):1309–1316. doi:10.1080/10426914.2010.512648

Li CB, Chen MH, Yuan ST, Liu LM (2012) Effect of welding speed in high speed laser-TIG welding of magnesium alloy. Mater Manuf Process 27(12):1424–1428. doi:10.1080/10426914.2012.700144

Cao R, Yu G, Chen JH, Wang P-C (2013) Cold metal transfer joining aluminum alloys-to-galvanized mild steel. J Mater Process Technol 213(10):1753–1763. doi:10.1016/j.jmatprotec.2013.04.004

Li LQ, Tan CW, Chen YB, Guo W, Mei CX (2013) CO2 laser welding-brazing characteristics of dissimilar metals AZ31B Mg alloy to Zn coated dual phase steel with Mg based filler. J Mater Process Technol 213(3):361–375. doi:10.1016/j.jmatprotec.2012.10.009

Lin J, Ma N, Lei Y, Murakawa H (2013) Shear strength of CMT brazed lap joints between aluminum and zinc-coated steel. J Mater Process Technol 213(8):1303–1310. doi:10.1016/j.jmatprotec.2013.02.011

Tan CW, Li LQ, Chen YB, Mei CX, Guo W (2013) Interfacial microstructure and fracture behavior of laser welded-brazed Mg alloys to Zn-coated steel. Int J Adv Manuf Tech 68(5-8):1179–1188. doi:10.1007/s00170-013-4910-4

Taguchi G (1978) Performance analysis design. Int J Prod Res 16(6):521–530

Sacks J, Welch WJ, Mitchell TJ, Wynn HP (1989) Design and analysis of computer experiments. Stat Sci 409–423

Eberhart RC, Shi Y (2000) Comparing inertia weights and constriction factors in particle swarm optimization. Ieee C Evol Computat: 84–88. doi:10.1109/CEC.2000.870279

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, P., Cao, L., Zhou, Q. et al. Optimization of welding process parameters by combining Kriging surrogate with particle swarm optimization algorithm. Int J Adv Manuf Technol 86, 2473–2483 (2016). https://doi.org/10.1007/s00170-016-8382-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8382-1