Abstract

Experimental forming limit curves (FLCs) were determined for two different grades of low-carbon steel: interstitial free (IF) and drawing quality (DQ). The grades had different interstitial content, clear differences in microstructural evolution, and differences in experimental FLCs. Microstructural evolution was generalized in terms of developments in crystallographic texture and in-grain misorientations. These were extrapolated further into dynamic values of normal anisotropy (\( \overline{r} \)) and strain hardening exponent (n), respectively. FLCs were simulated by finite element (FE) analysis. Simulations were conducted using constant (or initial) and dynamic material properties (namely, \( \overline{r} \) and n). Simulations using the dynamic variation in the material properties showed better comparison to the experimental FLCs.

Similar content being viewed by others

References

Goodwin GM (1968) Application of strain analysis to sheet metal forming problems in press shop. Trans SAE paper no. 680093; Vol. 77

Keeler SP, Backofen WA (1946) Plastic instability and fracture in sheets stretched over rigid punches. Trans ASM 56:30–48

Keeler SP (1965) Determination of forming limits in automotive stampings. Sheet Met Ind 42:683–695

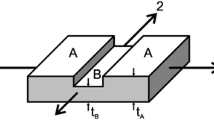

Hecker SS (1975) Simple technique for determining forming limit curves. Sheet Met Ind 52:671–675

Tadros AK, Mellor PB (1978) An experimental study of the in-plane stretching of sheet metal. Int J Mech Sci 20:121–134

Gronostajski J, Dolny A (1980) Memories Sci Rev Metall 4:570–578

Raghavan KS (1995) A simple technique to generate in-plane forming limit curves and selected application. Metall Trans A 26:2075–2084

Sing WM, Rao KP (1993) Influence of material properties on sheet metal formability limits. J Mater Process Technol 37:37–51

Lu ZH, Lee D (1987) Prediction of history-dependent forming limits by applying different hardening models. Int J Mech Sci 29:123–137

Nakamachi E (1995) Sheet-forming process characterization by static-explicit anisotropic elastic–plastic finite-element simulation. J Mater Process Technol 50:116–132

Yoshida T, Kayayama T, Usuda M (1995) Forming-limit analysis of hemispherical-punch stretching using the three-dimensional finite-element method. J Mater Process Technol 50:226–237

Takuda H, Mori K, Takakura N, Yamaguchi K (2000) Finite element analysis of limit strains in biaxial stretching of sheet metals allowing for ductile fracture. Int J Mech Sci 42:785–798

McGinty RD, McDowell DL (2004) Application of multiscale crystal plasticity models to forming limit diagrams. J Eng Mater Technol 126:285–291

Campos HB, Butuc MC, Grácio JJ, Rocha JE, Duarte JMF (2006) Theoretical and experimental determination of the forming limit diagram for the AISI 304 stainless steel. J Mater Process Technol 179:56–60

Aretz H (2007) Numerical analysis of diffuse and localized necking in orthotropic sheet metals. Int J Plast 23:798–840

Ganjiani M, Assempour A (2007) An improved analytical approach for determination of forming limit diagrams considering the effects of yield functions. J Mater Process Technol 182:598–607

Signorelli JW, Bertinetti MA, Turner PA (2009) Predictions of forming limit diagrams using a rate-dependent polycrystal self-consistent plasticity model. Int J Plast 25:1–25

Hora P, Tong L, Reissner J (1996) A prediction method of ductile sheet metal failure in FE simulation. In: Numisheet 1996, Dearborn, Michigan, USA, pp 252–256

Mattiasson K, Sigvant M, Larson M (2006) Methods for forming limit prediction in ductile metal sheets. In: IDDRG 2006. Porto, Portugal, pp 1–9

Franz G, Abed-Meraim F, Ben Zineb T, Lemoine X, Berveiller M (2009) Role of intragranular microstructure development in the macroscopic behavior of multiphase steels in the context of changing strain paths. Mater Sci Eng A 517(1–2):300–311

Franz G, Abed-Meraim F, Ben Zineb T, Lemoine X, Berveiller M (2013) Strain localization analysis for single crystals and polycrystals: towards microstructure-ductility linkage. Int J Plast 48:1–33

Franz G, Abed-Meraim, Balan T, Altmeyer G (2014) Investigation and comparative analysis of plastic instability criteria: application to forming limit diagrams. Int J Adv Manuf Technol 71:1247–1262

Clift SE, Hartly P, Sturgess CEN, Rowe GW (1990) Fracture prediction in plastic deformation processes. Int J Mech Sci 32:1–17

Takuda H, Mori K, Hatta N (1999) The application of some criteria for ductile fracture to the prediction of the forming limit of sheet metals. J Mater Process Technol 95:116–121

Ozturk F, Lee D (2004) Analysis of forming limits using ductile fracture criteria. J Mater Process Technol 147:397–404

Nandedkar VM (2000) Formability studies on deep drawing quality steel. PhD thesis, IIT Bombay, Mumbai

Yerra SK, Vankudre HV, Date PP, Samajdar I (2004) Effect of strain path on the formability of a low carbon steel—on the textural and microtextural developments. J Eng Mater Technol 126:53–61

Raveendra S, Kanjarla AK, Paranjape H, Mishra SK, Mishra S, Delannay L, Samajdar I, Van Houtte P (2011) Strain mode dependence of deformation texture developments: microstructural origin. Metall Trans A 42A:2113–2124

Franz G, Abed-Meraim F, Lorrain J-P, Zineb TB, Lemoine X, Berveiller M (2009) Ellipticity loss analysis for tangent moduli deduced from a large strain elastic–plastic self-consistent model. Int J Plast 25:205–238

Böhlke T, Bondár G, Estrin Y, Lebyodkin MA (2009) Geometrically non-linear modeling of the Portevin–Le Chatelier effect. Comput Mater Sci 44:1076–1088

Franz G, Abed-Meraim F, Zineb TB, Lemoine X, Berveiller M (2011) Impact of intragranular microstructure development on ductility limits of multiphase steels. Mater Sci Eng A 528:3777–3785

Hill R (1948) A theory of yielding and plastic flow of anisotropic metals. Proc Roy Soc Lond A 193:281–297

Nowell MM, Wright SI (2005) Orientation effects on indexing of electron backscattered diffraction patterns. Ultramicroscopy 103:41

Bunge HJ (1982) Texture analysis in materials science. Butterworths, London

Khatirkar R, Mani Krishna KV, Kestens LAI, Petrov R, Pant P, Samajdar I (2011) Strain localizations in ultra low carbon steel: exploring the role of dislocations. ISIJ Int 51(5):849–856

Verlinden B, Driver J, Samajdar I, Doherty RD (2007) Thermo-mechanical processing of metallic materials. ISBN–978-0-08-044497-0, Pergamon materials series – series ed. R.W. Cahn, Elsevier, Amsterdam

Ray RK, Jonas JJ, Hook RE (1994) Cold rolling and annealing textures in low carbon and extra low carbon steels. Int Mater Rev 39(4):129–171

Nandedkar VM, Samajdar I, Narashiman K (2001) Development of grain interior strain localizations during plane strain deformation of a deep drawing quality steel. ISIJ Int 41(12):1517

Van-Houtte P (1995) MTM-FHM software system, version 2. MTM, KU Leuven, Belgium

Van Houtte P, Li S, Seefeldt M, Delannay L (2005) Deformation texture prediction: from the Taylor model to the advanced Lamel model. Int J Plast 21:589–624

Delannay L, Jacques PJ, Kalidindi SR (2006) Finite element modeling of crystal plasticity with grains shaped as truncated octahedrons. Int J Plast 22:1879–1898

Gladman T (1997) The physical metallurgy of microalloyed steels. The Institute of Materials, London

Wang W, Wagoner RH, Wang XJ (1996) Measurement of friction under sheet forming conditions. Metall Mater Trans A 27A:3971–3981

Wilkund D, Rosen BG, Gunnarsson L (2008) Frictional mechanisms in mixed lubricated regime in steel sheet metal forming. Wear 264:474–479

Mishra SK, Sharvari GD, Pant P, Narasimhan K, Samajdar I (2009) Improved predictability of forming limit curves through microstructural inputs. Int J Metal Form 2:59–67

Hutchinson WB (1984) Development and control of annealing textures in low carbon steel. Int Mater Rev 29(1):25–42

Vadavadagi BH, Shekhawat SK, Narasimhan K, Samajdar I (2014) Improved prediction of strain distribution during mechanical and hydro-mechanical deep drawing processes using microstructure-based dynamic strain hardening and anisotropy. Int J Strain Anal Eng Des 50(1):51–60

Basavaraj V, Shekhawat SK, Narasimhan K, Samajdar I (2015) Constrained tensile stretching of steel strips under different lubrication: predicting macroscopic strain distributions with microstructural inputs. Int J Mater Form 8:327–339

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vadavadagi, B.H., Shekhawat, S.K., Samajdar, I. et al. Forming limit curves in low-carbon steels: improved prediction by incorporating microstructural evolution. Int J Adv Manuf Technol 86, 1027–1036 (2016). https://doi.org/10.1007/s00170-015-8224-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8224-6