Abstract

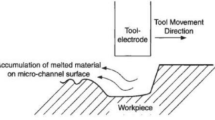

In this study, a tip-based channel fabricating method on aluminum alloy material is studied using different tip moving trajectories. A three-sided pyramidal tip is driven by a three-axis piezoelectric actuator to do the movements of the circle, the sharp ellipse (major axis along the feeding direction), and the flat ellipse (minor axis along the feeding direction) revolutions are the three kinds of moving trajectories used for machining. In each revolution, due to the shapes of tip and moving trajectory, there would be two cutting edges participating in machining process. Under these three trajectories, the variations of uncut chip thickness and cutting rake angle with tip revolving and the cutting length of every edge in each tip revolution are different, which results in different sizes of chips and burrs formed. Effects of these three moving trajectories on the material removal are studied in detail. Through processing experiments, it was found that without any deburring method, the channel machined using the sharp ellipse trajectory has two edges with no burr formed and could obtain better bottom surface quality with a smaller feed rate, while channels machined using the other two both have burrs at the right side, which results from the accumulation of chips. Finally, to eliminate or reduce this chip accumulation further, a three-dimensional moving trajectory is designed as a deburring method and used to process channels. It was found that this deburring method plays a significant role on the circle trajectory, but it is ineffective on the flat ellipse trajectory.

Similar content being viewed by others

References

Dornfeld D, Min S, Takeuchi Y (2006) Recent advances in mechanical micromachining. Ann CIRP Manuf Technol 55(2):745–768

Câmara MA, Rubio JCC, Abrão AM, Davim JP (2012) State of the art on micromilling of materials, a review. J Mater Sci Technol 28(8):673–685

Chae J, Park SS, Freiheit T (2006) Investigation of micro-cutting operations. Int J Mach Tools Manuf 46(3-4):313–332

Aurich JC, Dornfeld D, Arrazola PJ, Franke V, Leitz L, Min S (2009) Burr—analysis, control and removal. Ann CIRP Manuf Technol 58(2):519–542

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. Precis Eng 32(3):153–172

Heamawatanachai S, Bamberg E (2009) Design and characterization of a PZT driven micromachining tool based on single-point tool tip geometry. Precis Eng 33(4):387–394

Xue B, Yan YD, Li JR, Yu BW, Hu ZJ, Zhao XS, Cai Q (2015) Study on the micro-machining process with a micro three-sided pyramidal tip and the circular machining trajectory. J Mater Process Technol 217:122–130

Gozen BA, Ozdoganlar OB (2012) Design and evaluation of a mechanical nanomanufacturing system for nanomilling. Precis Eng 36(1):19–30

Park SS, Mostofa MG, Park CI, Mehrpouya M, Kim S (2014) Vibration assisted nano mechanical machining using AFM probe. Ann CIRP Manuf Technol 63(1):537–540

Vazquez E, Rodriguez CA, Zuniga AE, Ciurana J (2010) An experimental analysis of process parameters to manufacture metallic micro-channels by micro-milling. Int J Adv Manuf Technol 51(9-12):945–955

Chen PC, Pan CW, Lee WC, Li KM (2014) An experimental study of micromilling parameters to manufacture microchannels on a PMMA substrate. Int J Adv Manuf Technol 71(9-12):1623–1630

Focaroli S, Mazzitelli S, Falconi M, Luca G, Nastruzzi C (2014) Preparation and validation of low cost microfluidic chips using a shrinking approach. Lab Chip 14(20):4007–4016

Lekkala R, Bajpai V, Singh RK, Joshi SS (2011) Characterization and modeling of burr formation in micro-end milling. Precis Eng 35(4):625–637

Jeong YH, HanYoo B, Lee HU, Min BK, Cho DW, Lee SJ (2009) Deburring microfeatures using micro-EDM. J Mater Process Technol 209(14):5399–5406

Zhou Y, Gao YB, Wu BX, Tao S, Liu Z (2014) Deburring effect of plasma produced by nanosecond laser ablation. J Manuf Sci Eng Trans ASME 136(2):024501–024501-5

Kienzler A, Deuchert M, Schulze V (2009) Burr minimization and removal by micro milling strategies or micro peening process. In: Proceedings of the CIRP international conference on Burrs—analysis, control and removal. 237-243

Lee KL, Dornfeld DA (2005) Micro-burr formation and minimization through process control. Precis Eng 29(2):246–252

Yuan ZJ, Zhou M, Dong S (1996) Effect of diamond tool sharpness on minimum cutting thickness and cutting surface integrity in ultraprecision machining. J Mater Process Technol 62(4):327–330

Heaney PJ, Sumant AV, Torres CD, Carpick RW, Pfefferkorn FE (2008) Diamond coatings for micro end mills: enabling the dry machining of aluminum at the micro-scale. Diam Relat Mat 17(3):223–233

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 33(4):402–407

Bao WY, Tansel IN (2000) Modeling micro-end-milling operations. Part I: analytical cutting model. Int J Mach Tools Manuf 40(15):2155–2173

Ng CK, Melkote SN, Rahman M, Kumar AS (2006) Experimental study of micro- and nano-scale cutting of aluminum 7075-T6. Int J Mach Tools Manuf 46(9):929–936

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, Y., Xue, B., Hu, Z. et al. Machining slight burr formed micro-channels with different moving trajectories of a pyramidal diamond tip. Int J Adv Manuf Technol 84, 2037–2046 (2016). https://doi.org/10.1007/s00170-015-7853-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7853-0