Abstract

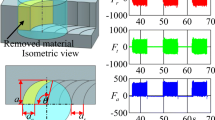

Tool wear on the cutting edges of micro end mills is an important issue affecting process outputs such as tool deflections and surface roughness, especially when difficult-to-cut materials such as titanium alloys, stainless steel, etc. are machined at micro scale. An understanding of the interactions between tool wear, machining forces, tool deflections, and surface roughness is important in order to maintain component quality requirements. However, in literature, the number of studies concerning tool wear in micro end mills is limited. The goal of the paper is to better understand tool wear patterns (flank wear, edge rounding) of micro end mills and their relationship to machining parameters. In this study, first, the influence of tool wear on micro milling forces and surface roughness parameters is analyzed and favorable micro milling process parameters are identified. It is shown that, when machining with worn end mills, forces are affected by the tool wear patterns. Then, the influence of increased milling forces due to tool wear on tool deflections and tool breakage is studied using both experimental techniques and finite element analysis. The finite element model-based tool deflection and tool breakage predictions are validated through experiments. The results of this study can be used in process parameter selection in pocket micro milling operations and tool condition monitoring systems.

Similar content being viewed by others

References

Davim JP, Jackson MP (Ed.) (2009) Nano and micromachining. ISTE-Wiley, London ISBN: 978-1-84821-103-2

Chae J, Park SS, Freiheit T (2006) Investigation of micro-cutting operations. Int J Mach Tools Manuf 45(3–4):313–332

Li H, Lai X, Li C, Feng J, Ni J (2008) Modelling and experimental analysis of the effects of tool wear, minimum chip thickness and micro tool geometry on the surface roughness in micro-end-milling. J Micromech Microeng 18:025006

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 33:402–407

Karpat Y (2009) Investigation of the effect of cutting tool edge radius on material separation due to ductile fracture in machining. Int J Mech Sci 51(7):541–546

Vogler MP, Kapoor SG, DeVor RE (2004) On the modeling and analysis of machining performance in micro-end milling, part II: cutting force prediction. Trans ASME J Manuf Sci Eng 126(4):695–705

Abdelrahman Elkaseer AM, Dimov SS, Popov KB, Minev RM (2014) Tool wear in micro-end milling: material microstructure effects, modeling, and experimental validation. J Micro Nano Manuf 2

Li C, Lai X, Li H, Ni J (2007) Modeling of three-dimensional cutting forces in micro-end-milling. J Micromech Micro Eng 17:671–678

Uriarte L, Herrero A, Zatarain M, Santiso G, Lopéz de Lacalle LN, Lamikiz A, Albizuri J (2007) Error budget and stiffness chain assessment in a micromilling machine equipped with tools less than 0.3mm in diameter. Precis Eng 31(2007):1–12

Mamedov A, Layegh SE, Lazoglu I (2015) Instantaneous tool deflection model for micro milling. Int J Adv Manuf Technol. doi:10.1007/s00170-015-6877-9

Rodrigues P, Labarga JE (2014) Tool deflection model for micromilling process. Int J Adv Manuf Technol 76:199–207. doi:10.1007/s00170-014-5890-8

Mijušković G, Krajnik P, Kopač J (2015) Analysis of tool deflection in micro milling of graphite electrodes. Int J Adv Manuf Technol 76:209–217. doi:10.1007/s00170-013-5536-2

Bao WY, Tansel IN (2000) Modeling micro-end-milling operations. Part III: influence of tool wear. Int J Mach Tools Manuf 40(15):2193–2211

Camara MA, Campos Rubio JC, Abrao AM, Davim JP (2012) State of the art on micromilling of materials, a review. J Mater Sci Technol 28(8):673–685

Saedon JB, Soo SL, Aspinwall DK, Barnacle A, Saad NH (2012) Prediction and optimization of tool life in micromilling AISI D2 (~62 HRC) hardened steel International Symposium on Robotics and Intelligent Sensors 2012 (IRIS). Proc Eng 41:1674–1683

Thepsonthi T, Özel T (2014) An integrated toolpath and process parameter optimization for high-performance micro-milling process of Ti–6Al–4V titanium alloy. Int J Adv Manuf Technol 75:57–75. doi:10.1007/s00170-014-6102-2

Cardoso P, Davim JP (2010) Optimization of surface roughness in micromilling. Mater Manuf Process 25(10):1115–1119

Oliaei SNB, Karpat Y (2014) Experimental investigations on micro milling of Stavax stainless steel, Procedia CIRP 14: 377–382 (6th CIRP International Conference on High Performance Cutting, HPC2014)

Liu H, Sun Y, Geng Y, Shan D (2015) Experimental research of milling force and surface quality for TC4 titanium alloy of micro-milling. Int J Adv Manuf Technol 79:705–716. doi:10.1007/s00170-015-6844-5

Jun M, Devor RE, Kapoor SG, Englert F (2008) Experimental investigation of machinability and tool wear in micro-end milling. Trans NAMRI/SME 36:201–208

Arizmendi M, Campa FJ, Fernandez J, de LLN L, Gil A, Bilbao E, Veiga F, Lamikiz A (2009) Model for surface topography prediction in peripheral milling considering tool vibration. CIRP Ann Manuf Technol 58:93–96

Arizmendi M, Fernandez J, Lopez de Lacalle LN, Lamikiz A, Gil A, Sanchez JA, Campa FJ, Veiga F (2008) Model development for the prediction of surface topography generated by ball-end mills taking into account the tool parallel axis offset. CIRP Ann Manuf Technol 57:101–104

Leach R (2013) Characterisation of areal surface texture. Springer, Berlin

Altintas Y (2012) Manufacturing automation, metal cutting mechanics, machine tool vibrations and CNC design, 2nd edn. Cambridge University Press, Cambridge

Zhou L, Peng FY, Yana R, Yao PF, Yang CC, Li B (2015) Analytical modeling and experimental validation of micro end-milling cutting forces considering edge radius and material strengthening effects. Int J Mach Tools Manuf 97:29–41

Salgado MA, Lopez de Lacalle LN, Lamikiz A, Munoa J, Sanchez JA (2005) Evaluation of the stiffness chain on the deflection of end-mills under cutting forces. Int J Mach Tools Manuf 45:727–739

Fang ZZ (2005) Correlation of transverse rupture strength of WC-Co with hardness. Int J Refract Met Hard Mater 23(2):119–127

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oliaei, S.N.B., Karpat, Y. Influence of tool wear on machining forces and tool deflections during micro milling. Int J Adv Manuf Technol 84, 1963–1980 (2016). https://doi.org/10.1007/s00170-015-7744-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7744-4